56 | IM-112 DECEMBER 2019

Vertical Turbine Pumps

2001299 - VTP- IOM

56 | IM-112 DECEMBER 2019

Vertical Turbine Pumps

2001299 - VTP- IOM

Vertical Turbine Pumps

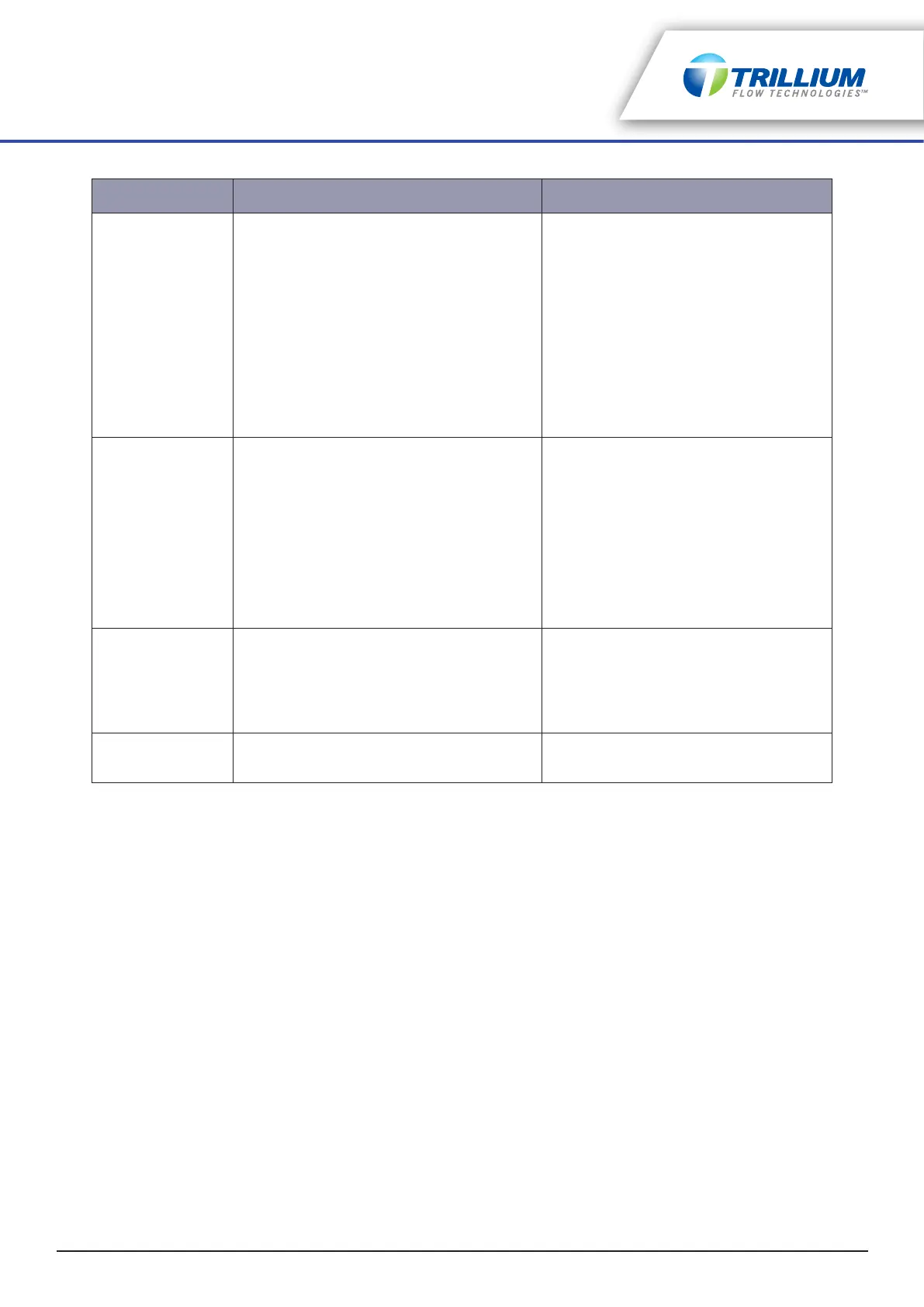

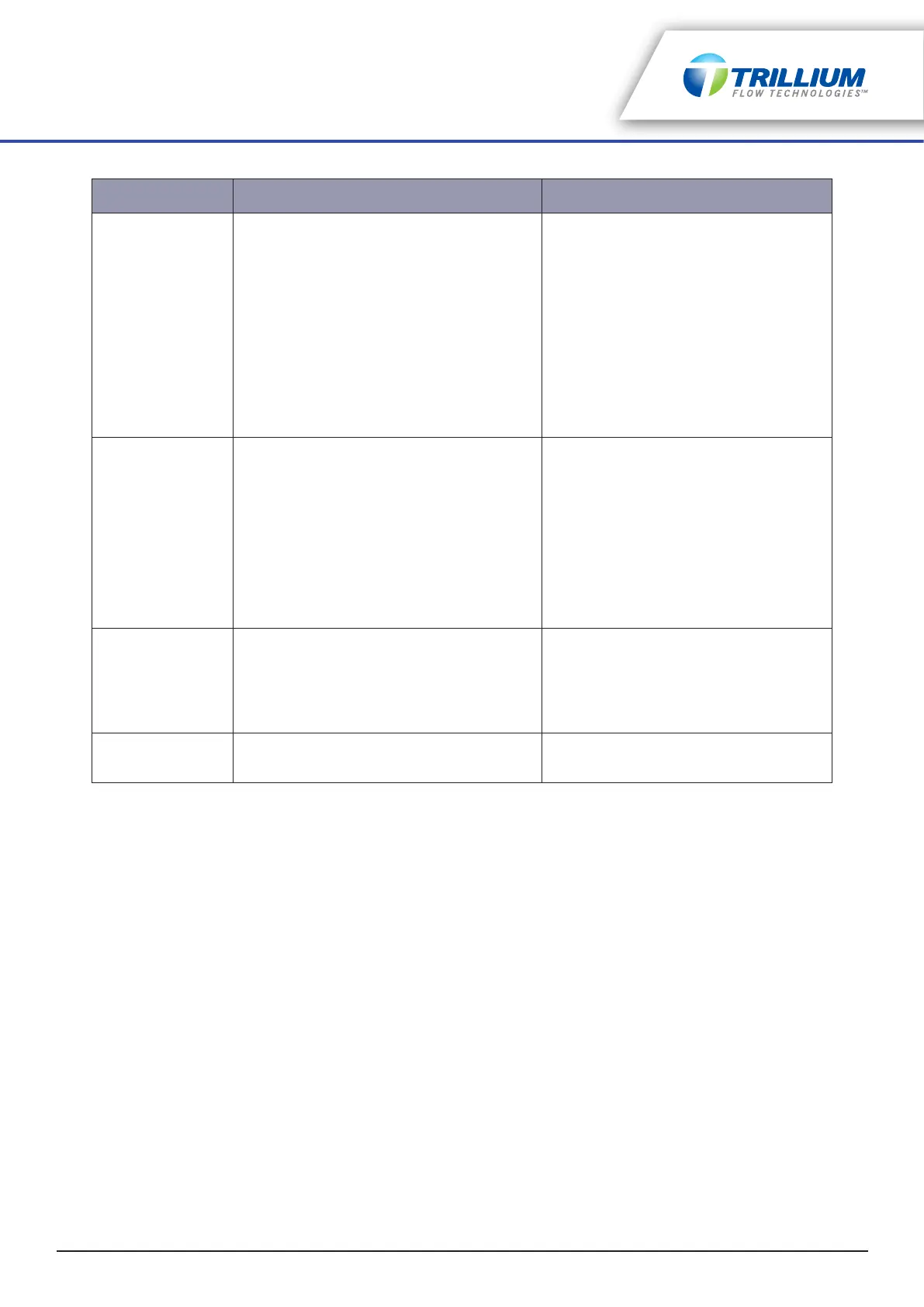

Troubleshooting

Document Name: 2001299-VTP-IOM-EN Page 56 of 67

Revision 3 Copyright © 2014, Weir Floway, Inc. All Rights Reserved. Issue Date: December 12, 2014

Motor overloaded. 1 Line voltage not correct.

2 Faulty equipment used to check.

3 Specific gravity higher than design.

4 Operation at point on pump curve other than

design.

5 Motor speed too high.

6 Impellers dragging.

7 Pump in bind.

1 Check and correct.

2 Check equipment.

3 Correct specific gravity or re-evaluate

system.

4 Check performance curve.

5 Line voltage too high or incorrect

frequency.

6 Readjust.

7 Pull master switch, rotate pump by hand

to check. Disassemble the unit to

determine the cause.

Pump vibrating

excessively and

making noise.

1 Unit running backwards.

2 Pump breaking suction and pumping air.

3 Loose fasteners.

4 Badly worn motor or pump bearings.

5 Impeller(s) loose on shaft.

6 Pump & motor shafts misaligned.

7 Stress due to piping misalignment.

1 Refer to

“Hollow Shaft Driver Installation”

on page 24, step 12.

2 Lower pump or reduce capacity or

increase fluid level.

3 Check all bolts, nuts, and re-tighten.

4 Pull unit and repair.

5 Pull unit and repair.

6 Pull unit and repair.

7 Correct.

Excess wear 1 Abrasives.

2 Pump in bind.

3 Vibration.

1 Clean system.

2 Pull master switch, rotate pump by hand

to check. Disassemble the unit to

determine the cause.

3 Determine cause and correct.

Corrosion 1 Impurities.

2 Corrosive liquid.

1 Analyze the fluid.

2 Change to corrosion resistant materials.

Condition Probable Cause Remedy

Table 10-1: Troubleshooting Chart (Continued)

Loading...

Loading...