MC095 - MCP-8 Control Unit Section 4 - Programming

53

Feeder Timeout:

When the Feeder is stopped, a programmed timeout (from 5 to 60 seconds duration) delays station movement to or

from the tipsealer pad. If the Feeder is restarted before the timeout ends, the valves remain in the dispensing position.

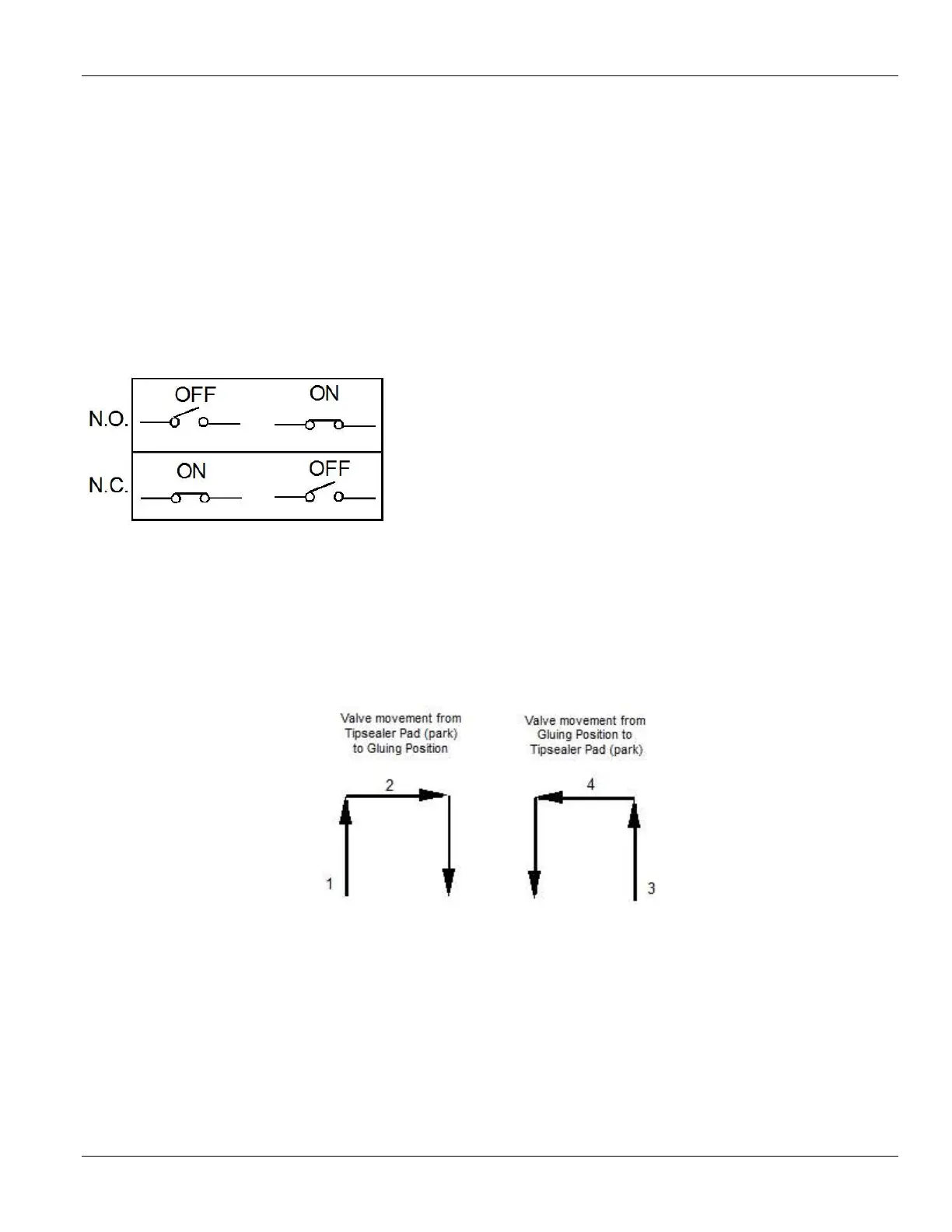

Feed Signal Polarity:

Allows the following Feed Signal options (polarity):

N.O.

Feeder is Normally Open (Off).

N.C.

Feeder is Normally Closed (On).

If the Valves move to the Tipsealer Pad when the Feeder is Active (ON), or move to the dispensing position when the

Feeder is Off, the polarity is incorrect.

Reverse the polarity setting to correct it.

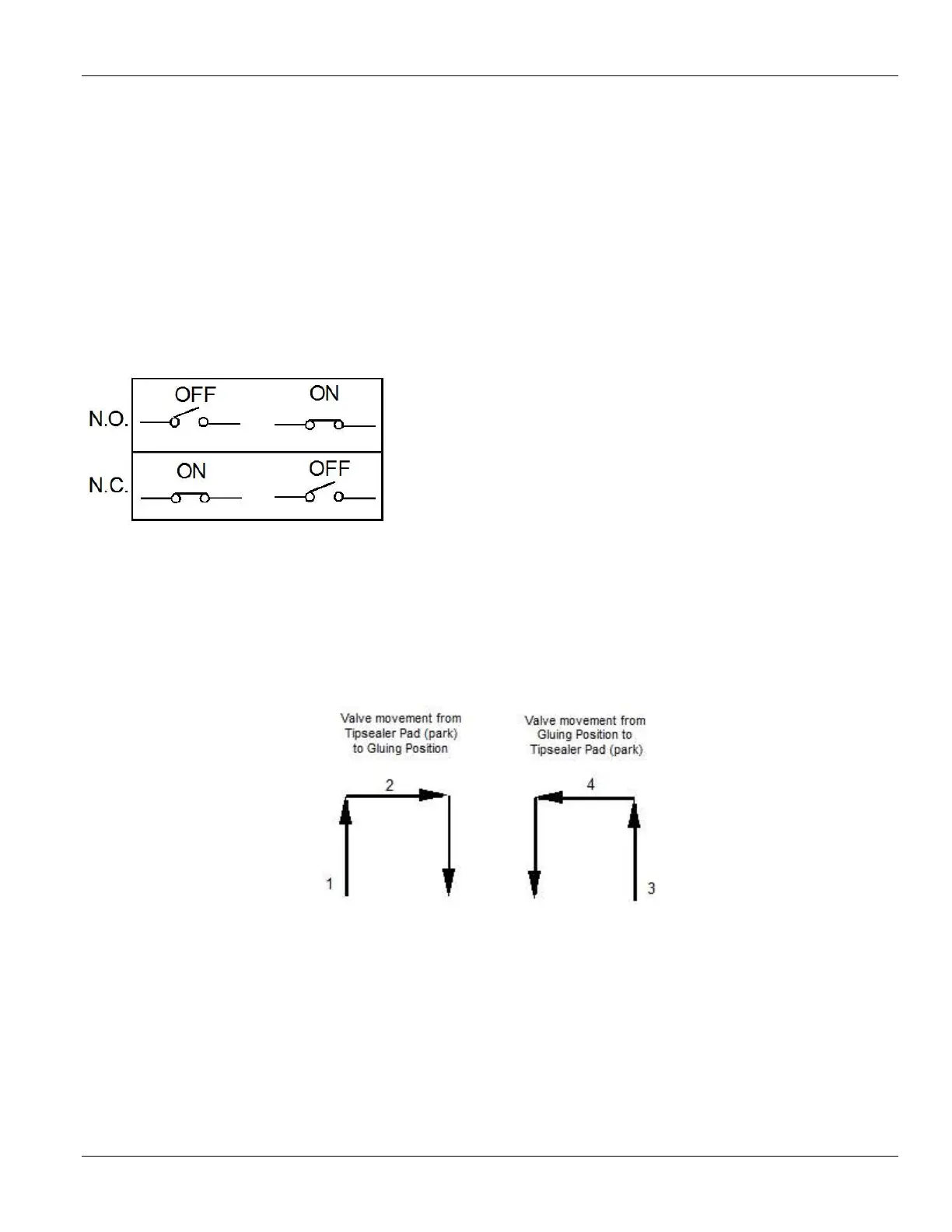

Delay Time (1-4):

These settings, designated by number (1-4), set the delay (in miliseconds) for each valve motion to or from the

Tipsealer Pad (refer to the figure, below).

Output Manual Mode:

When the station is switched to Manual Mode, the controls allow an alarm to activate, or for a relay to shut down the

system until the station is set back to Auto Mode.

The Manual Mode function allows to operator to manually move the valves off the Tipsealer to clean the nozzles. If

the manual mode switch is not set back to auto, the Tipsealer will be disabled during future machine stops. The

Manual Mode button is located on the air manifold control box, located near the glue station.

Manual Mode output options:

Off

Alarm 1

Alarm 2

Relay

Loading...

Loading...