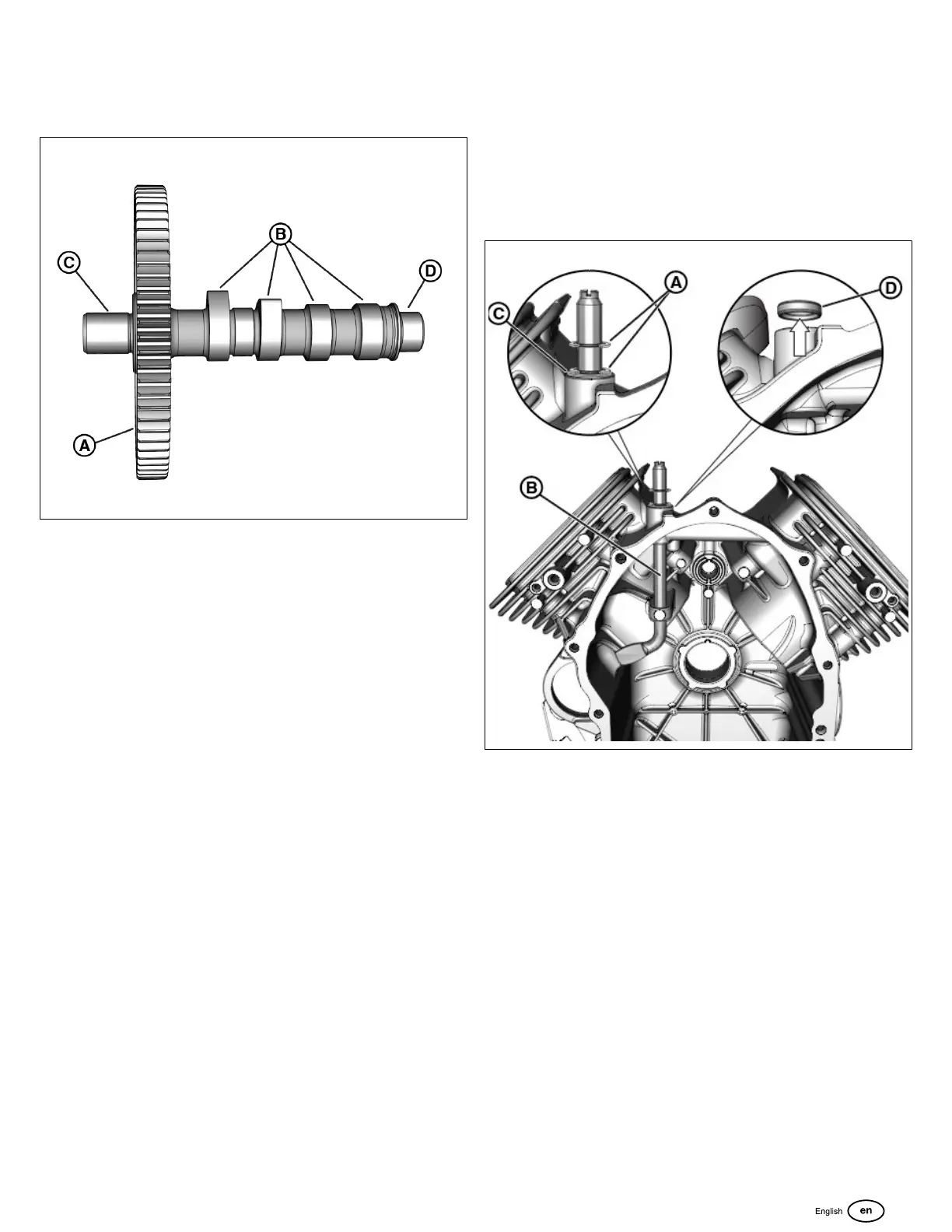

Camshaft

1. Check camshaft gear (A, Figure 130) for worn, cracked,

chipped, or missing teeth.

130

2. Check camshaft lobes (B) for scratching, scoring, or

excessive wear.

3. Check MAG bearing journal (C) and PTO bearing journal

(D) for scratching or scoring.

4. Using an outside micrometer, measure the MAG bearing

journal and PTO bearing journal diameters. Replace the

camshaft if either measurement is 0.783in (19.897mm)

or less.

CRANKCASE AND CRANKCASE COVER

Governor Shaft and Seal - Disassembly

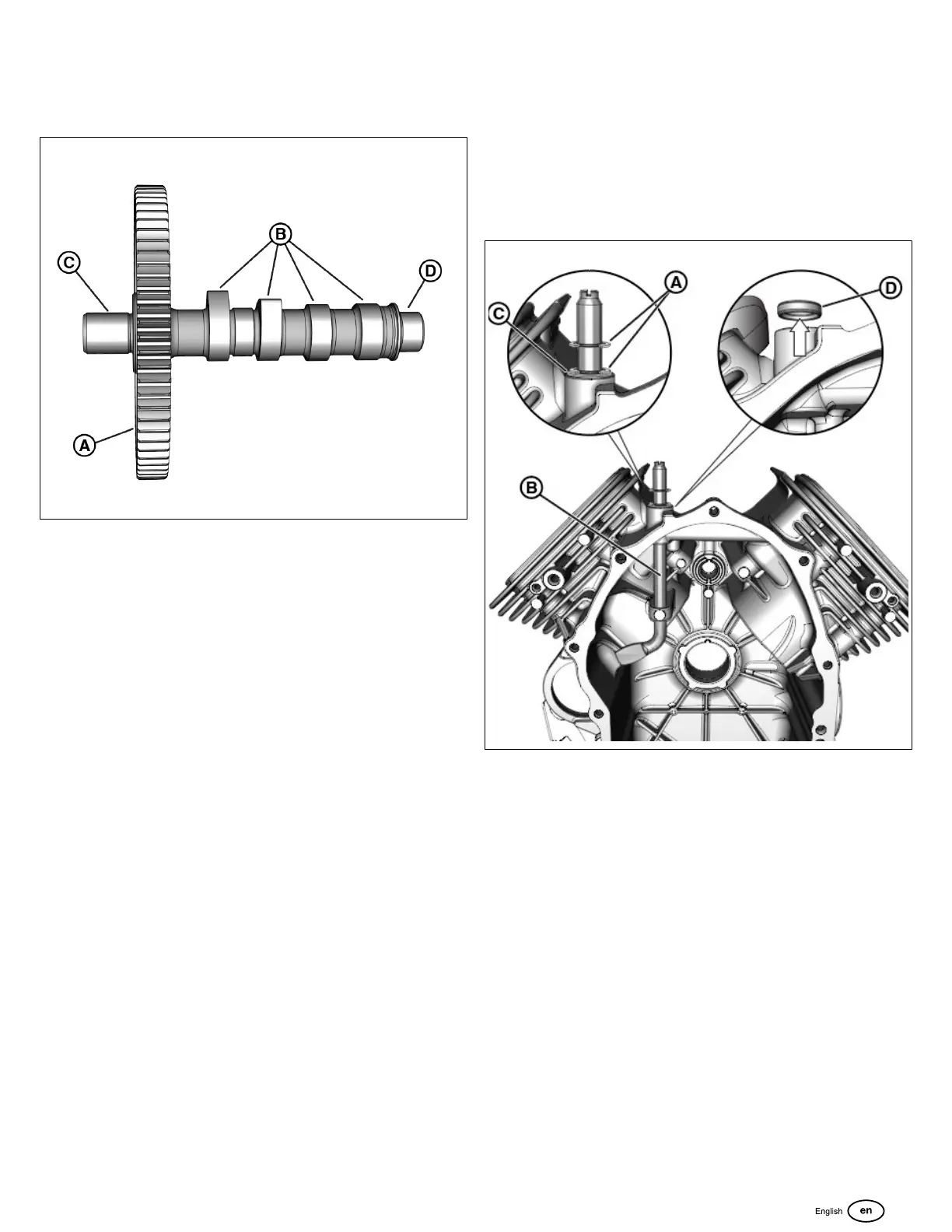

1. If equipped, remove C-clips (A, Figure 131) from top 2

grooves in governor shaft(B) and bottom groove within

the crankcase. Discard C-clips.

131

2. Remove flat washer(C)from crankcase boss.

3. Remove governorshaftfrom inside crankcase.

4. Using a small pick, remove oil seal(D)from crankcase

bore. Exercise caution to avoid scratching bore during

seal removal.

Governor Shaft and Seal - Assembly

1. Install new governor shaft oil seal (D, Figure 131). Press

seal into shaft bore until seal edge is level with bore lip.

2. From inside the crankcase, install the governor shaft (B)

up through the crankcase shaft bore. Make sure to avoid

damaging the new oil seal.Make sure that the paddle of

the governor shaft is orientated as pictured in Figure 131.

3. Install the flat washer (C)over the governor shaft and

onto the crankcase boss.

4. If equipped, install new C-clips onto the top 2 grooves of

the governor shaft and on the bottom groove within the

crankcase.

105

Loading...

Loading...