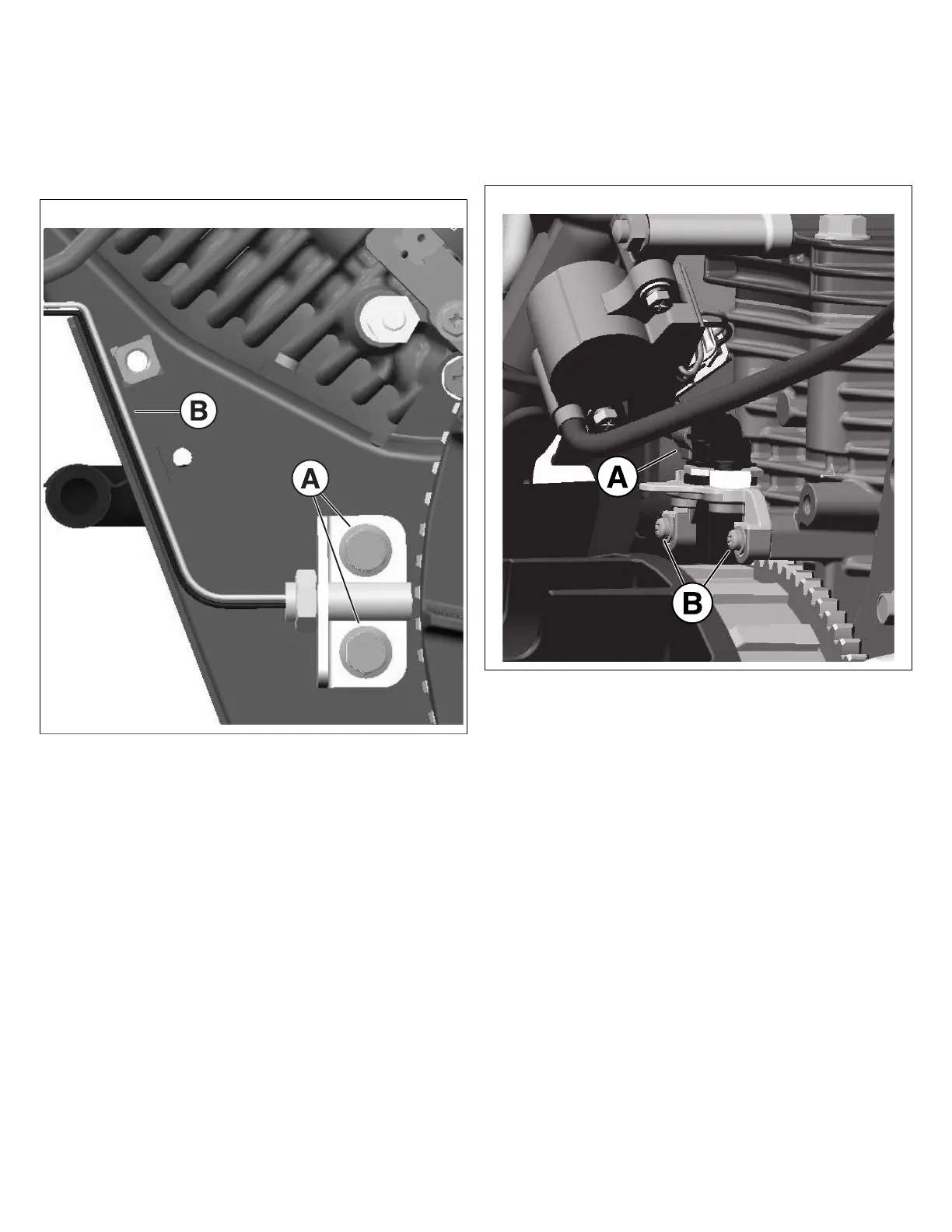

Optional Speed Sensor

1. Install the speed sensor onto the engine back plate. Align

the 2 mounting holes with the threaded back plate holes.

2. Start by hand the 2 sensor fasteners (A, Figure 193).

Tighten until fastener head makes light contact with the

sensor mounting.

193

3. Using a feeler gauge, adjust the air gap between the

sensor head and the flywheel teeth to 0.015in(0.38 mm).

4. While maintaining the specified sensor air gap, tighten

the sensor fasteners to 60 lb-in (6.8 Nm).

NOTE: DO NOT overtighten the sensor fasteners. Damage

to the sensor casing may occur.

5. Route the sensor wiring along the engine back plate (B).

The wiring will be OUTSIDE of the blower housing.

6. Connect the wire harness connector to the sensor wire

connector.

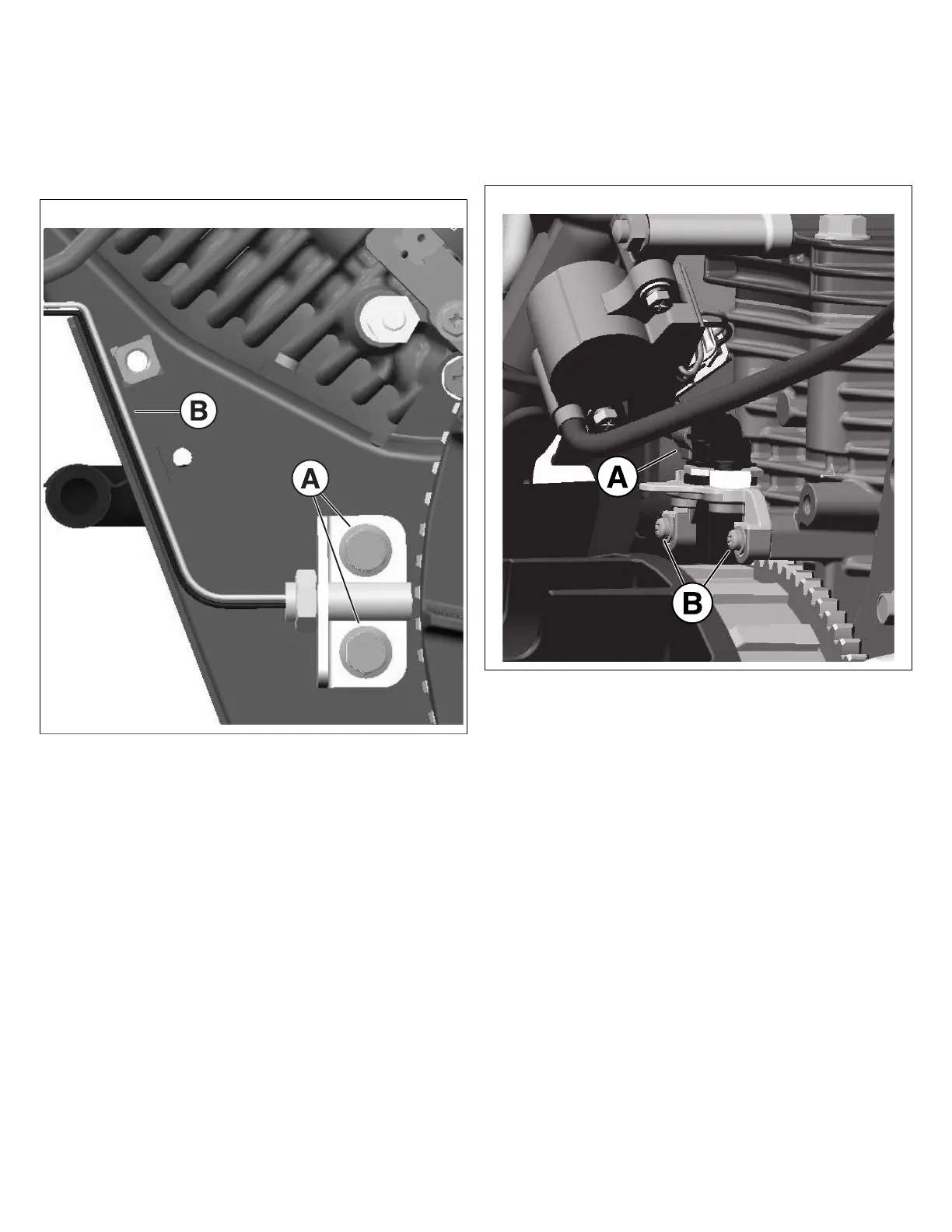

Crankshaft Position Sensor(CKP)

1. Install the crankshaft position sensor onto the crankcase

bosses above the flywheel on the cylinder 1 side of the

engine.

2. Apply a small amount of threadlocker (see

SPECIFICATIONS - Engine Fluids and Sealant

Specifications) CKP fastener threads. Start the 2 sensor

fasteners (B, Figure 194)by hand.Tighten until the

fastener head makes contact with the sensor. DO NOT

overtighten as the sensor air gap needs to be adjusted

prior to final torqueing.

194

3. Using a feeler gauge, adjust the sensor air gap to 0.010

in (0.25 mm).

4. While maintaining the specified sensor air gap, tighten

the 2 sensor fasteners to 23 lb-in (2.6 Nm).

5. Connect the wire harness connector to the crankshaft

position sensor electrical connector (A).

Engine Control Module(ECM) - EFI

Depending on the engine trim, an externally mounted ECM

may be equipped. For installation instructions, proceed as

follows:

1. Install the ECM onto the mounting bracket.

146 vanguardpower.com

Loading...

Loading...