2. Install oil scavenge hose fitting and hose as follows:

A. Apply a light film of clean engine oil to new o-ring (C)

of oil scavenge pump hose fitting (D). Install o-ring

onto fitting.

NOTE: Verify that old o-ring is not present in the

crankcase cover bore. Inadvertently stacking old and

new o-rings will result in oil leaks.

B. Install oil scavenge pump hose fitting into crankcase

cover bore closest to the cylinder heads, and hand

tighten until snug. Tighten hose fitting to 215 lb-in

(24.3 Nm).

C. Install oil scavenge hose connector (with redclip

lock)onto fitting. Push inclip lockto secure.

3. Install crankcase ventilation hoseconnector(with

blueclip lock)onto fitting. Push inclip lock to secure.

4. Install oil supply check valve, hose fitting, and hose as

follows:

A. Install oil supply check valve (E) into crankcase

cover bore farthest from the cylinder heads. Tighten

check valve to 375 lb-in (42.4 Nm).

B. Apply a light film of clean engine oil to new o-ring (F)

of oil supply pump hose fitting (G).Install o-ring onto

fitting.

NOTE: Verify that old o-ring is not present in the

check valve bore. Inadvertently stacking old and new

o-rings will result in oil leaks.

C. Install hose fitting into check valve and tighten to 325

lb-in (36.7 Nm).

5. Prime oil supply pump as follows:

NOTE:Failure to prime oil supply gerotor pump will

result in air pockets in the lubrication system and can

lead to catastrophic engine damage.

A. If available, obtain green rubber cap used to keep

dust and dirt out of fitting during shipping. Install

rubber cap onto fitting to act as an oil seal during

priming.

B. Obtain standard oil can with a pointed nozzle. Verify

that nozzle is clean of dirt and grit, and then push

through rubber cap.

C. Add 3 ounces (88.7 ml) of oil. Remove and discard

rubber cap.

D. Install oil supply hose connector (with greenclip

lock) onto fitting. Push inclip lock to secure.

Oil Pressure Switch

1. Thoroughly clean the threads of the oil pressure switch to

remove any dirt or debris.

2. Snuglywrap thread sealing tape around the threads of

the switch 2-3 times in a counter-clockwise direction.

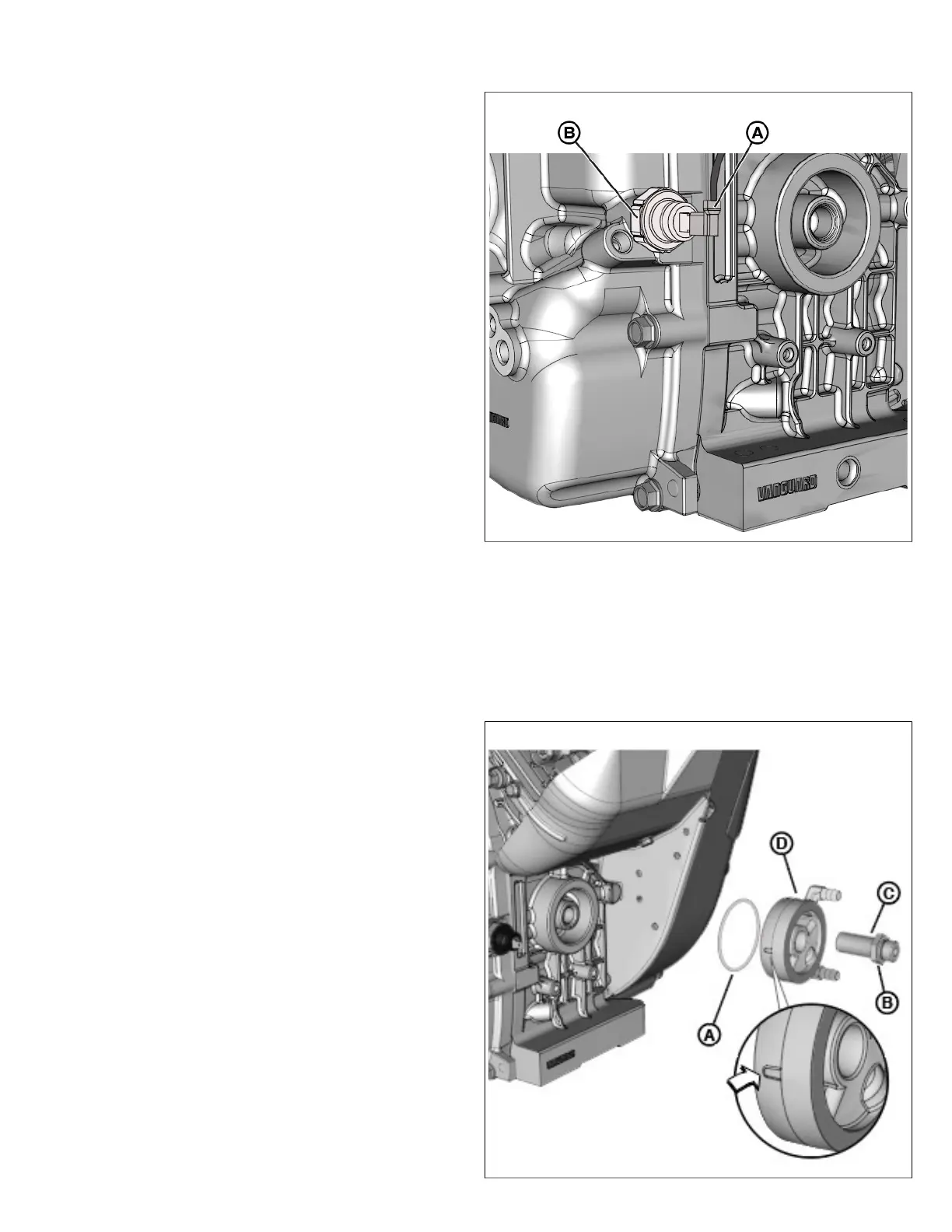

3. Start by hand the switch (B, Figure 225)into the

crankcase. Tighten to 15 lb-in (1.7 Nm).

225

4. Connect the harness spade connector (A) to the switch

spade contact.

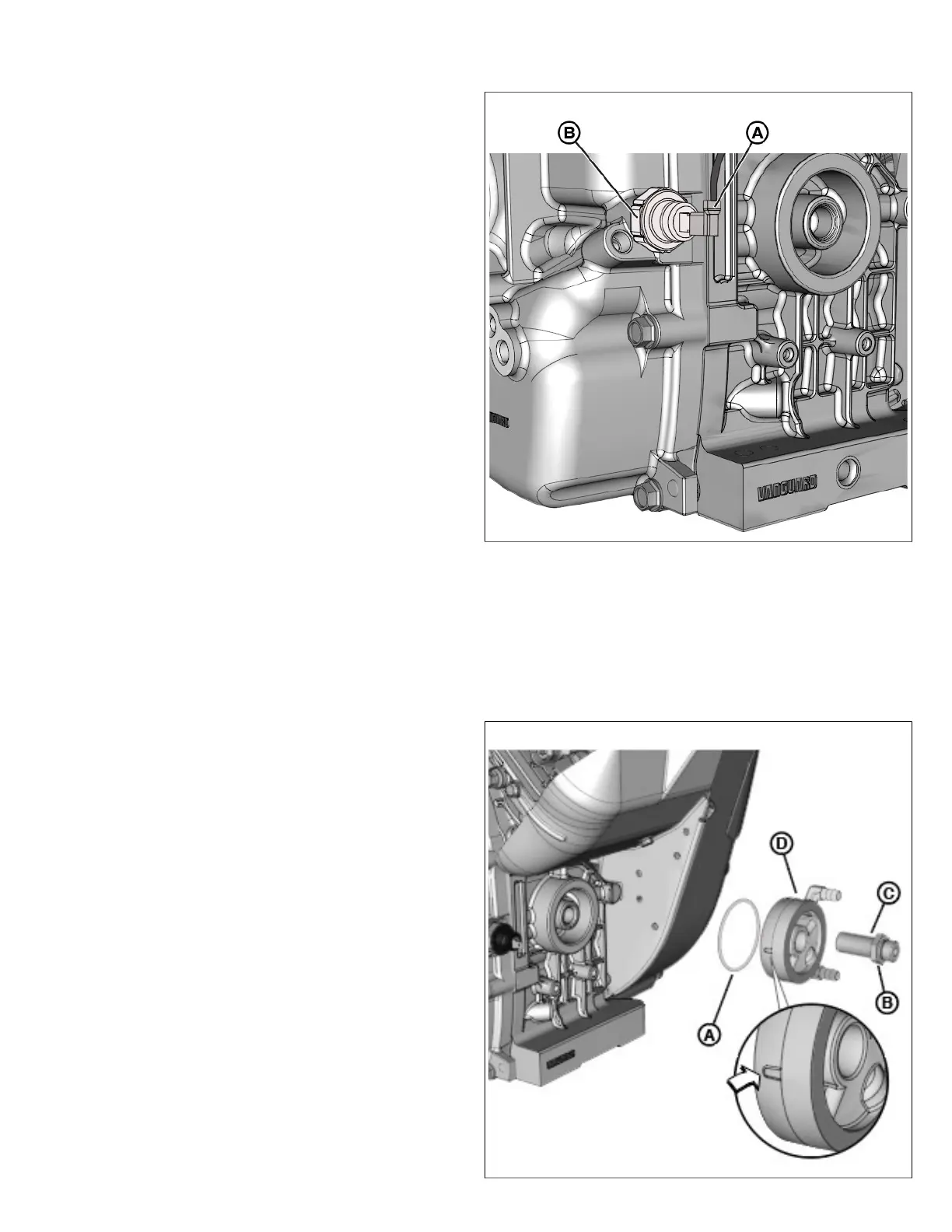

Oil Diverter Valve and Drip Tray

1. Inspect o-ring(A, Figure 226)in diverter groove for

cuts, tears, or general deterioration. Install new o-ring, if

necessary.

226

160 vanguardpower.com

Loading...

Loading...