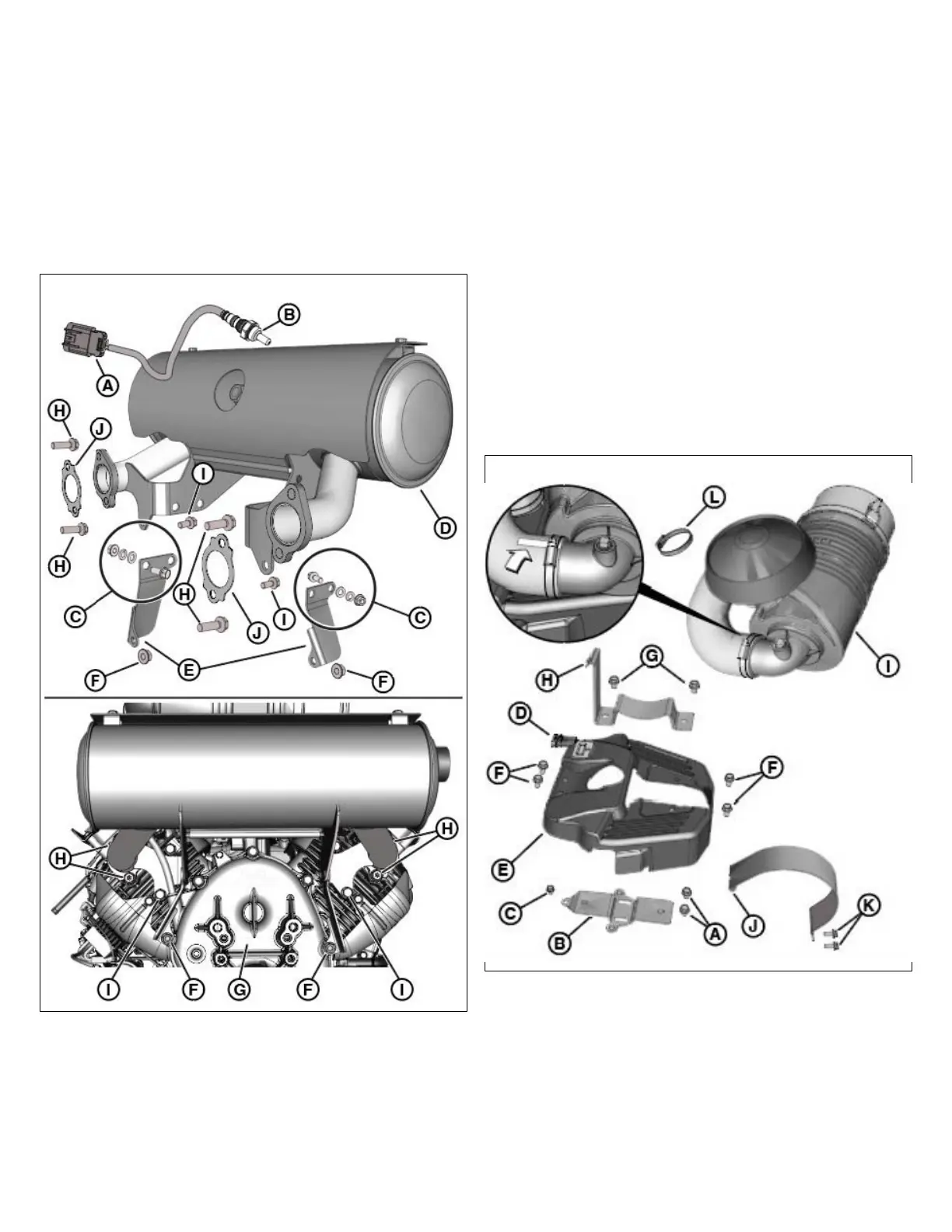

Muffler

1. If equipped with optional muffler bracket support,

proceed as follows:

A. Install 2 fasteners (F, Figure 218) to fasten bracket

supports (E) to crankcase cover () studs. Tighten to

195 lb-in (22 Nm).

B. Install fastener, flat washer, lock washer, and hex

nut (C) to fasten muffler (D) bracket to bracket

supports. Tighten nuts to 195 lb-in (22 Nm).

218

2. Verify that exhaust manifold and cylinder head flanges

are clean and dry. Install new gaskets (J) onto exhaust

manifold flanges.

3. Apply anti-seize compound to threads of 4 fasteners (H),

and then install to fasten muffler manifolds to cylinder

heads. Tighten fasteners to 195 lb-in (22 Nm).

NOTE: Depending on your engine model and trim, the

mufflermanifold to cylinder head fastener may be replaced

with studs and nuts.Apply anti-seize compound to threads of

studs and tighten nuts to 195 lb-in(22 Nm).

4. Install 2 fasteners (I) to fasten muffler bracket to

crankcase. Tighten screws to 195 lb-in (22 Nm).

5. If removed, rotate sensor body hex clockwise to fasten

O

2

sensor (B) to muffler. Tighten sensor to 160 lb-in (18

Nm).

6. Connect O

2

sensor connector (A).

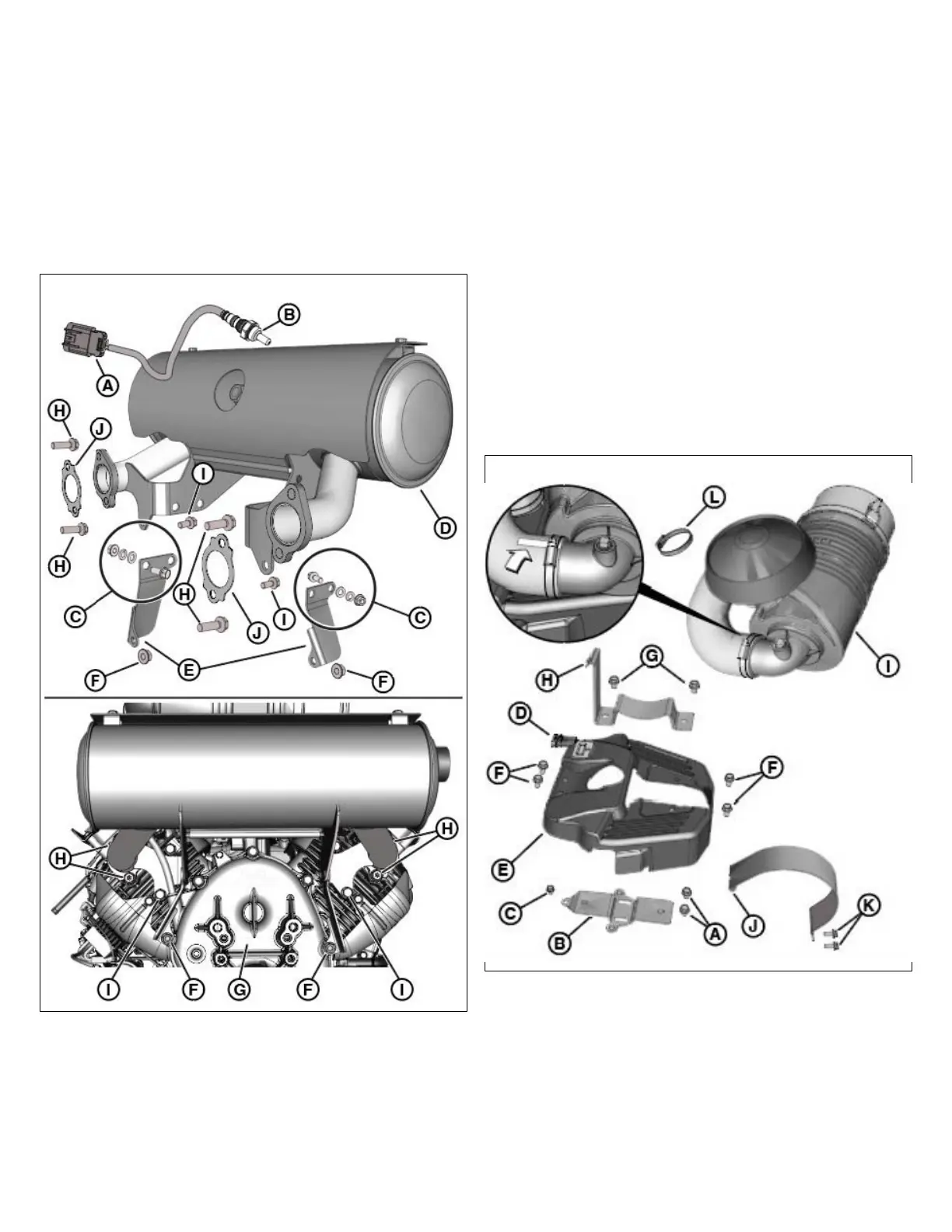

Air Cleaner Assembly - Cyclonic

1. Install 2 fasteners (A, Figure 219) to secure air cleaner

bottom bracket (B) to fuel pump module bracket support.

Tighten to 138 lb-in (15.6 Nm).

219

2. Install fastener (C) to secure air cleaner bottom bracket

to air intake elbow. Tighten to 90 lb-in (10.2 Nm).

3. If equipped, connect MIL/tachometer/hourmeter

connector (D) at back of top cover (E).

4. Install 4 fasteners (F) to secure top cover toair intake

elbow and air cleaner bottom bracket. Alternately tighten

to 90 lb-in (10.2 Nm).

5. Install 2 fasteners (G) to secure air cleaner top bracket

(H) to air cleaner bottom bracket. Tighten to 138 lb-in

(15.6 Nm).

156 vanguardpower.com

Loading...

Loading...