REMOVE EXTERNAL ASSEMBLIES

Preliminary Instructions

Prior to starting any repair or maintenance operation.

Make sure you are familiar withALL safety warnings and

procedures as outlined in SECTION 1 - SAFETY AND

GENERAL INFORMATION - Safety Information.

ALWAYS wear safety glasses and gloves while performing

any maintenance and repair operation.

1. Remove spark plug wires from spark plug terminals.

Secure spark plug wires to prevent unintentional contact

with spark plug terminals.

2. Place engine on a flat, level surface.

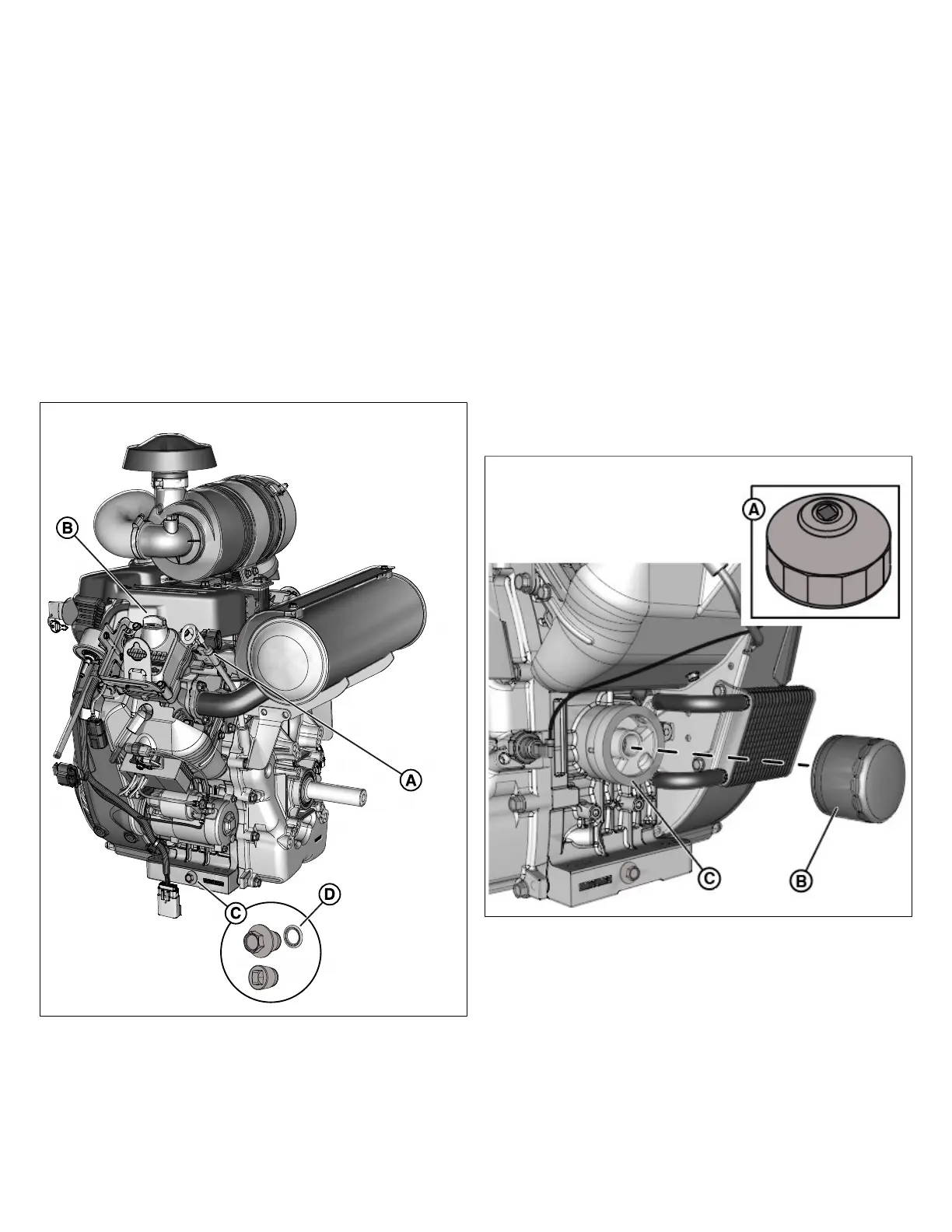

3. Remove dipstick (A,Figure 31)and wipe with a clean,

lint free cloth.

31

4. Remove oil fill cap (B) from valve cover.

5. Remove oil drain plugs (C) at base of engine and drain

oil into an approved container. Remove and discard drain

plug O-rings (D), if equipped.

6. Dispose of used oil and oil filter at a proper waste

disposal or recycling center.

Relieve Fuel System Pressure- EFI and EFI-ETC

1. Turn Ignition OFF.

2. Loosen fuel filler cap to relieve fuel tank pressure.

Tighten filler cap after loosening.

3. Remove access cover. See Engine Covers in this

section.

4. Remove air cleaner assembly. See Air Cleaner Assembly

in this section.

5. Pull out gray secondary lock and press to disconnect fuel

pump module connector.

6. Turn Ignition ON, Engine ON.

7. Start and run engine until it stalls. If it does not start,

crank engine a few times to relieve fuel system pressure.

Oil Filter

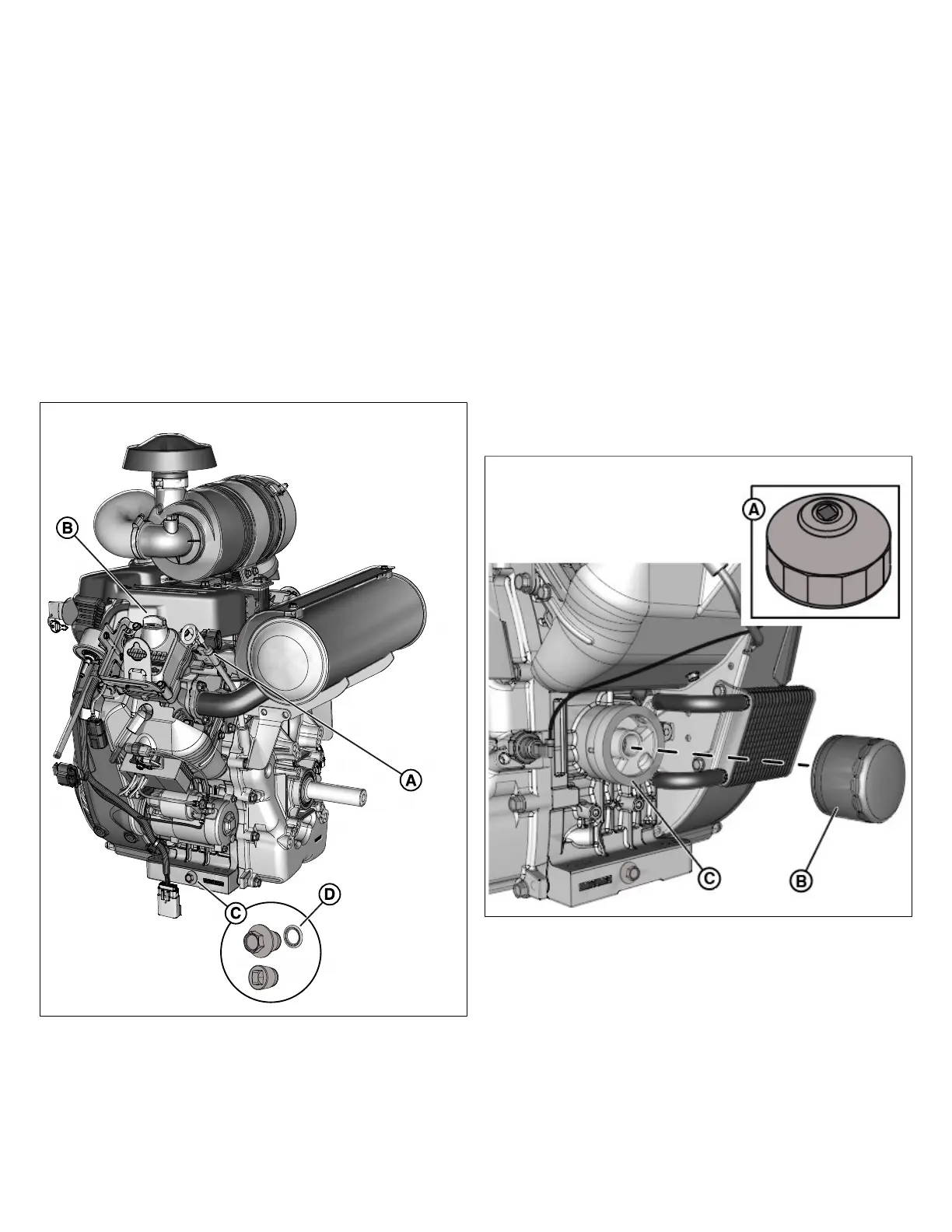

1. Obtain a 76mm-14 Flute end cap style oil filter wrench

(A, Figure 32).

32

2. With the oil filter wrench attached to a ratchet and

extension bar,turn oil filter(B)in a counterclockwise

direction until loose, and then remove by hand. Do not

use air tools.

3. Clean the oil filter mount flange (C) of any old gasket

material.

4. Discard old oil filter and oil in the appropriate receptacle.

50 vanguardpower.com

Loading...

Loading...