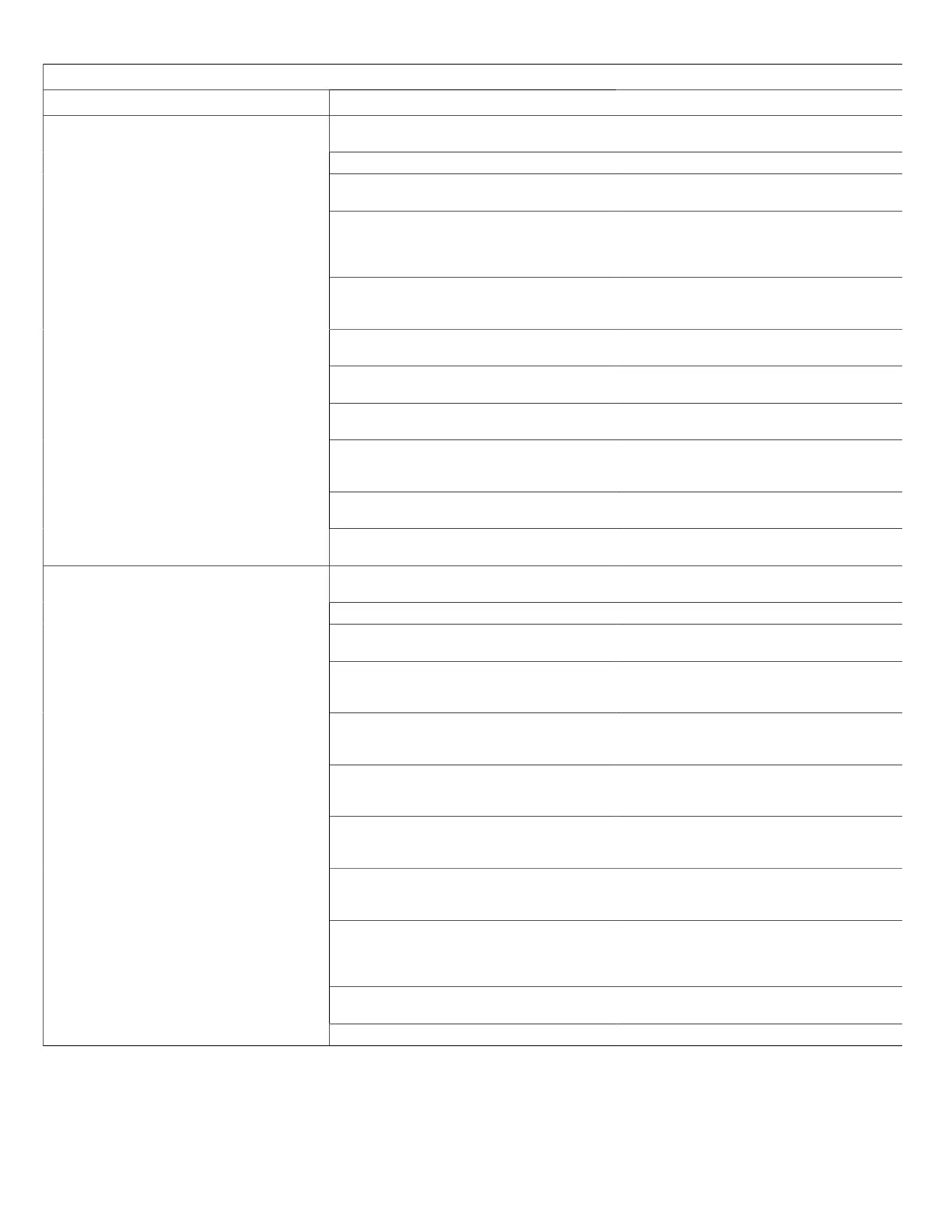

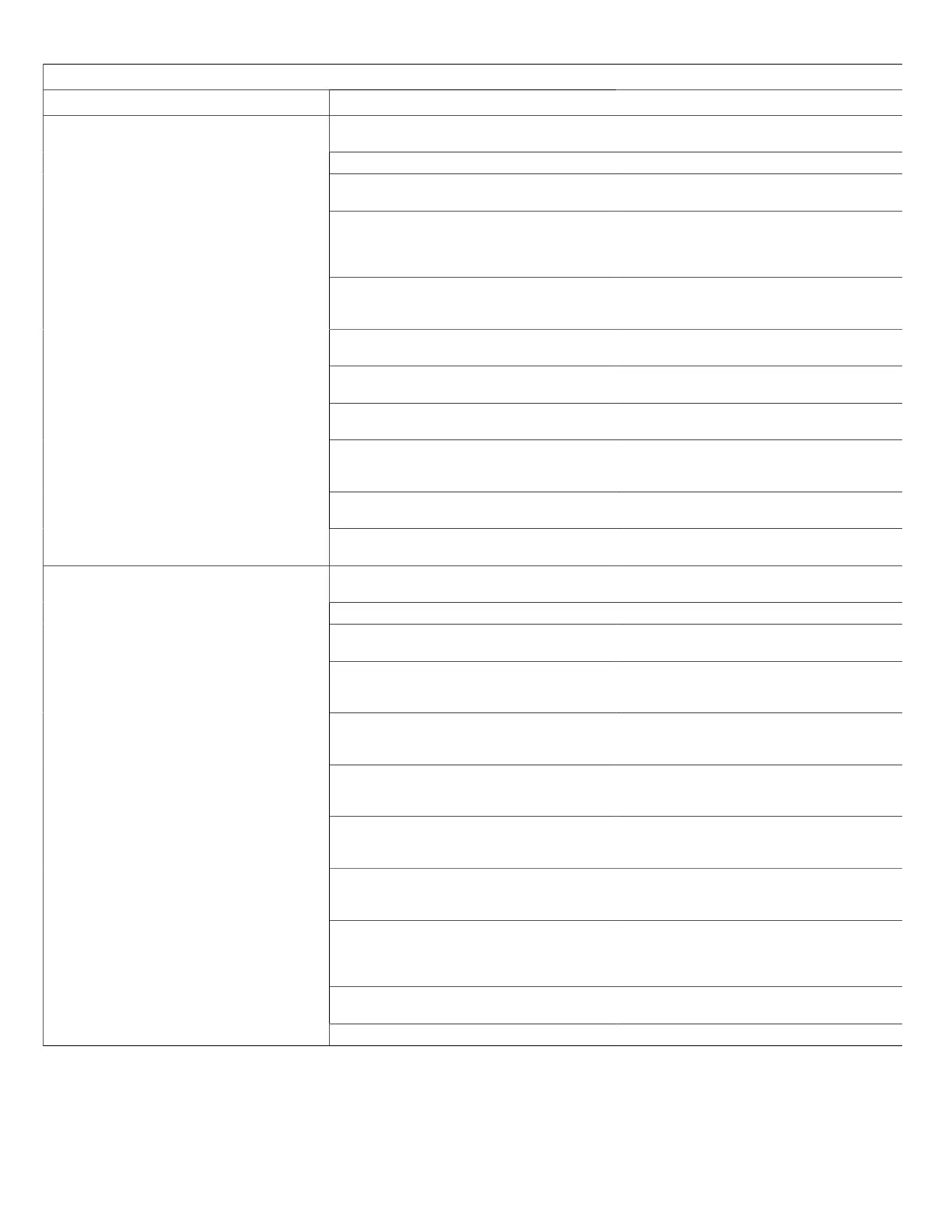

Gasoline-Fueled Engine Troubleshooting Chart

Gasoline-FueledEngine Troubleshooting Chart

Problem Potential Cause Action

Perform On-Board Diagnostics

(OBD) test (EFI engines)

See applicable EFI Diagnostic and

Repair manual for your engine

Choke partially closed (carbureted engines) Open choke fully

Carburetor out of adjustment Service carburetor. See SECTION6 - SERVICE

ENGINE SUBASSEMBLIES - Carburetor

Ignition improperly timed Check crankshaft/flywheel key for

wear or damage. See SECTION 6 -

SERVICE ENGINE SUBASSEMBLIES -

Flywheel, Crankshaft, Crankcase Cover

Low compression Check engine compression

components. See Check Compression

ComponentsCheck Compression Component

Low oil level Check engine oil level. See SECTION

2 - MAINTENANCE - Check Engine Oil

Air cleaner clogged or air intake restriction Clean or replace air filter. See SECTION 2

- MAINTENANCE - Clean/Replace Air Filter

Water or other contamination in fuel Drain tank, fuel system, and fuel

lines; replace with recommended fuel.

Low fuel pressure (EFI engines) Verify that fuel pressure is between 38 - 41

PSI (262 - 296 kPa). See applicable EFI

Diagnostic and Repair manual for your engine

Exhaust system restriction Clean exhaust ports; remove

and clean or replace muffler

Engine lacks power

Engine load too great Check equipment for damaged components,

worn bearings or debris buildup

Exhaust system leak Check exhaust manifold, muffler and all

gaskets for leaks. Replace as necessary

Engine does not run smoothly See "Engine surges, will not hold steady speed"

Loose or worn equipment; such as mower

blades, pulleys, gears, clutches, drive belts, etc.

Inspect and repair any equipment components

that may be loose, worn or damaged

Worn cylinder Inspect cylinder for wear. See SECTION

6 - SERVICE ENGINE SUBASSEMBLIES

- Crankcase and Crankcase Cove

Worn or loose connecting rod or crankshaft Inspect and replace worn or damaged

components. See SECTION 6 - SERVICE

ENGINE SUBASSEMBLIES - Connecting Rod

Bent crankshaft Replace crankshaft.See SECTION 6 -

SERVICE ENGINE SUBASSEMBLIES -

Flywheel, Crankshaft, Crankcase Cover

Loose flywheel Tighten flywheel nut. See SECTION 6 -

SERVICE ENGINE SUBASSEMBLIES -

Flywheel, Crankshaft, Crankcase Cover

Flywheel fan blades broken Replace flywheel fan. See

SECTION 5 -DISASSEMBLE

ENGINE - Bottom End Disassembly

Ignition improperly timed Check crankshaft/flywheel key for

wear or damage. See SECTION 6 -

SERVICE ENGINE SUBASSEMBLIES -

Flywheel, Crankshaft, Crankcase Cover

Loose external components Visually inspect engine and equipment for loose

components, air guides, shields and fasteners

Engine rattles, knocksor is noisy

Engine loose on equipment mounting Tighten mounting fasteners to correct specificati

34 vanguardpower.com

Loading...

Loading...