2. Delivery and set up

The place of set up should be selected in such a way that

■ There is sufficient lighting

■ The electrical power supply with safety socket and earth are installed close enough to the machine

that the power cable is not subject to any strain.

■ The power cable should also be dimensioned in such a way that a multiple socket can be used, for

example, to power a coolant system.

2.1 Transporting the machine

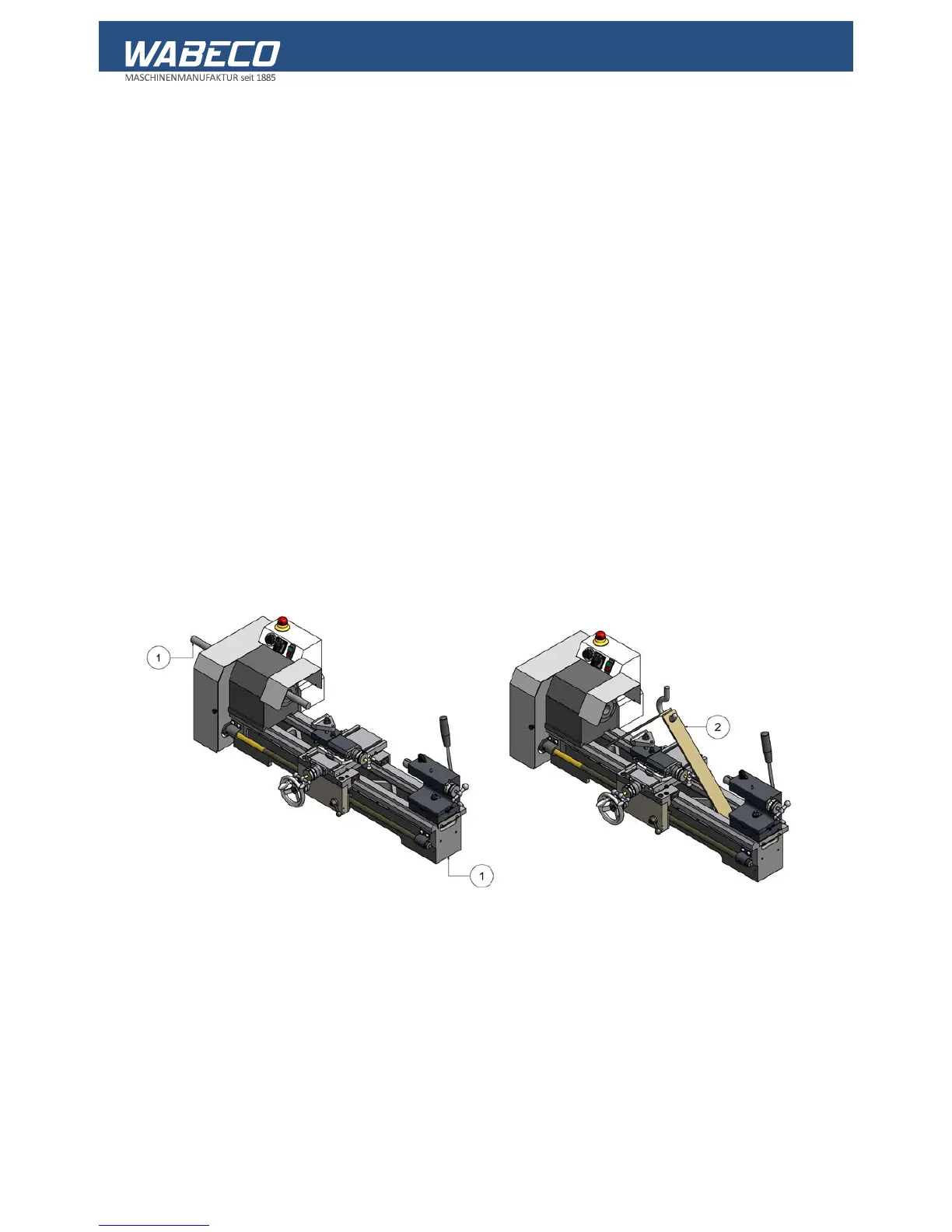

We recommend two people to lift the machine, using the positions shown (1).

To do this, a sufficiently dimensioned, at least Ø 20 mm steel rod is pushed through the main spindle.

The machine should be carried and balanced by one person at the steel rod and by the other person,

at the shown position on the opposite underside of the bed.

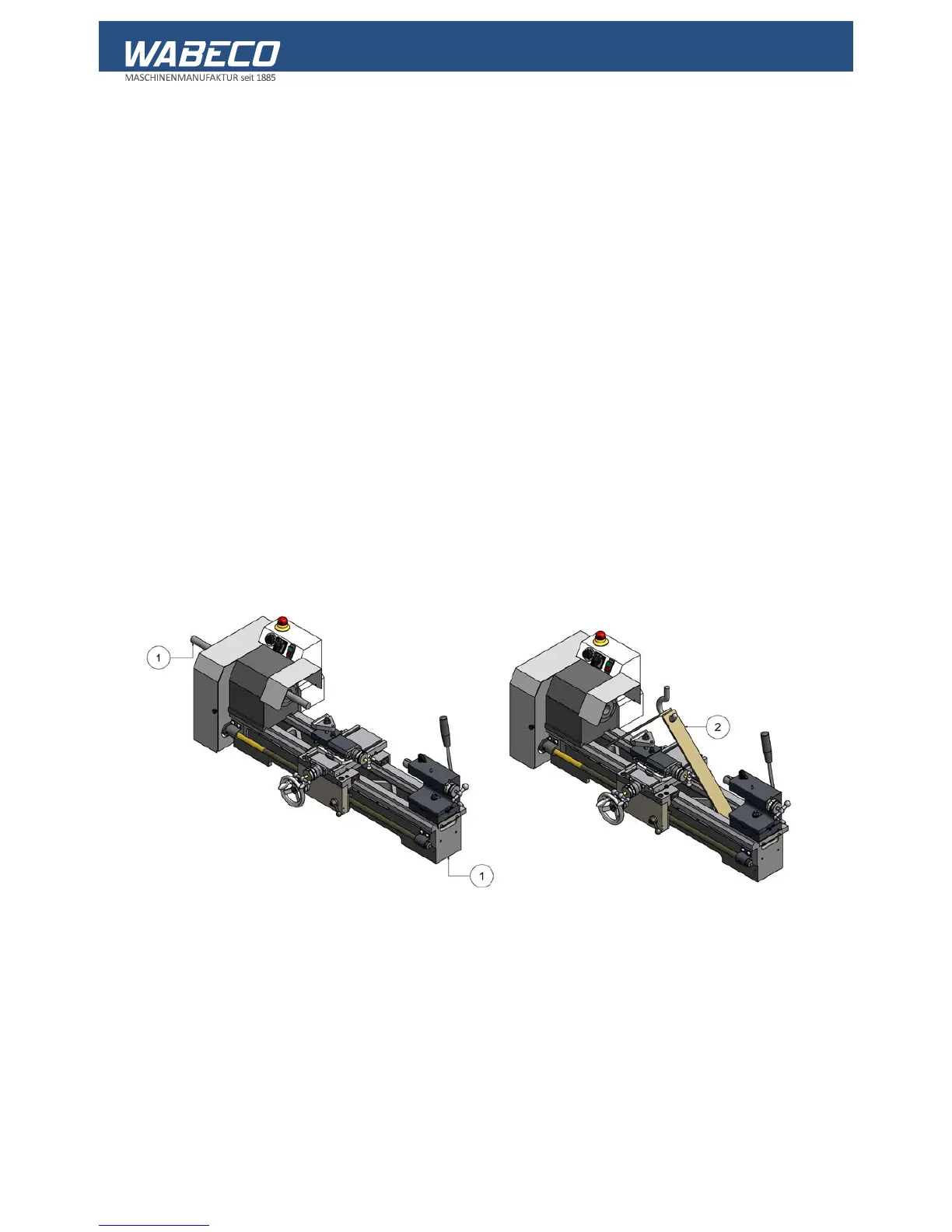

Due to the weight of the machine it is advisable to lift the machine by crane, if this is possible. To lift,

wrap suitable lashing (2) as shown around the two outer struts of the ribbing of the machine bed.

When lifting, pay attention to an ergonomic stance and sufficient safety!

In the delivered state, the machine feet have two transport straps attached. These secure the

machine to the transportation pallet. They must be removed before setting the machine up.

Loading...

Loading...