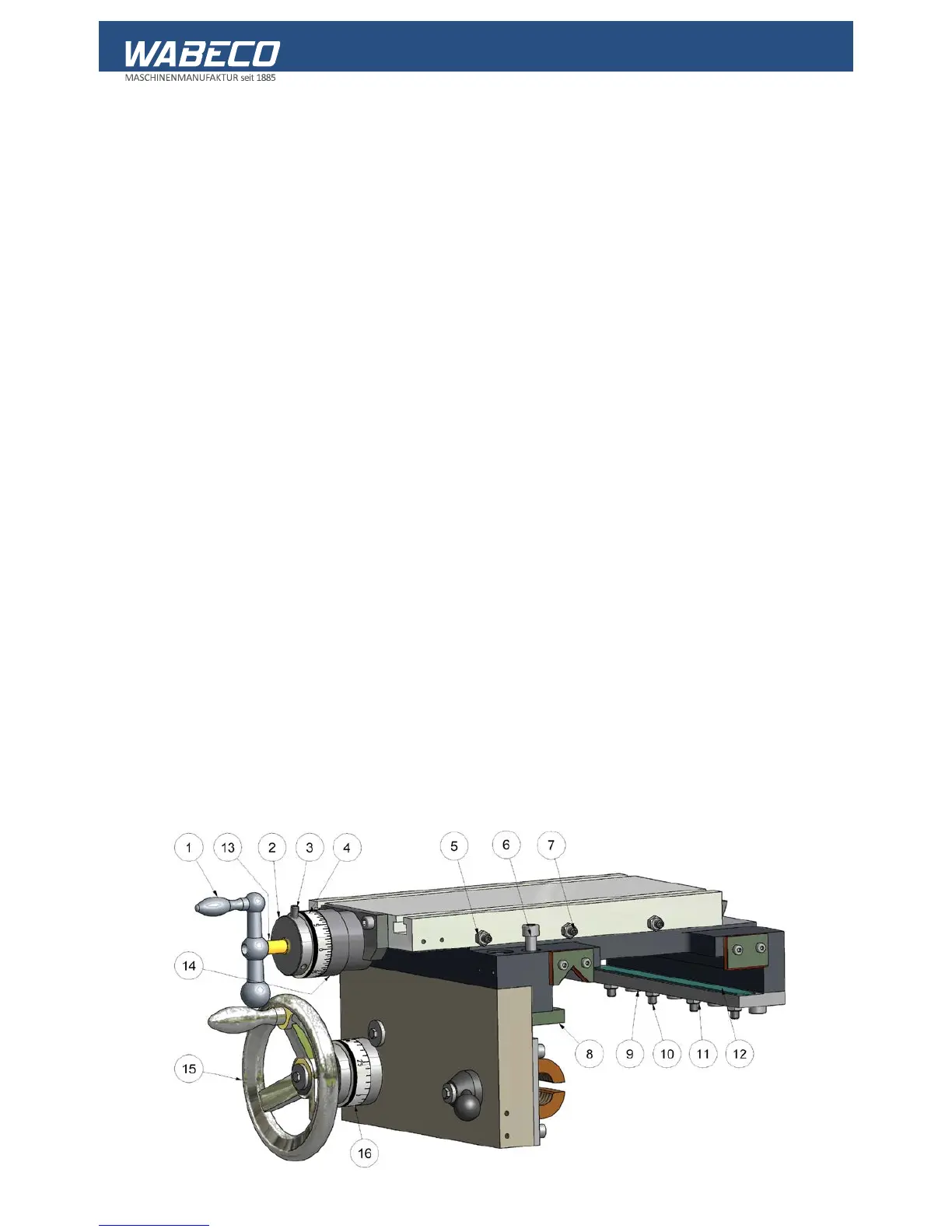

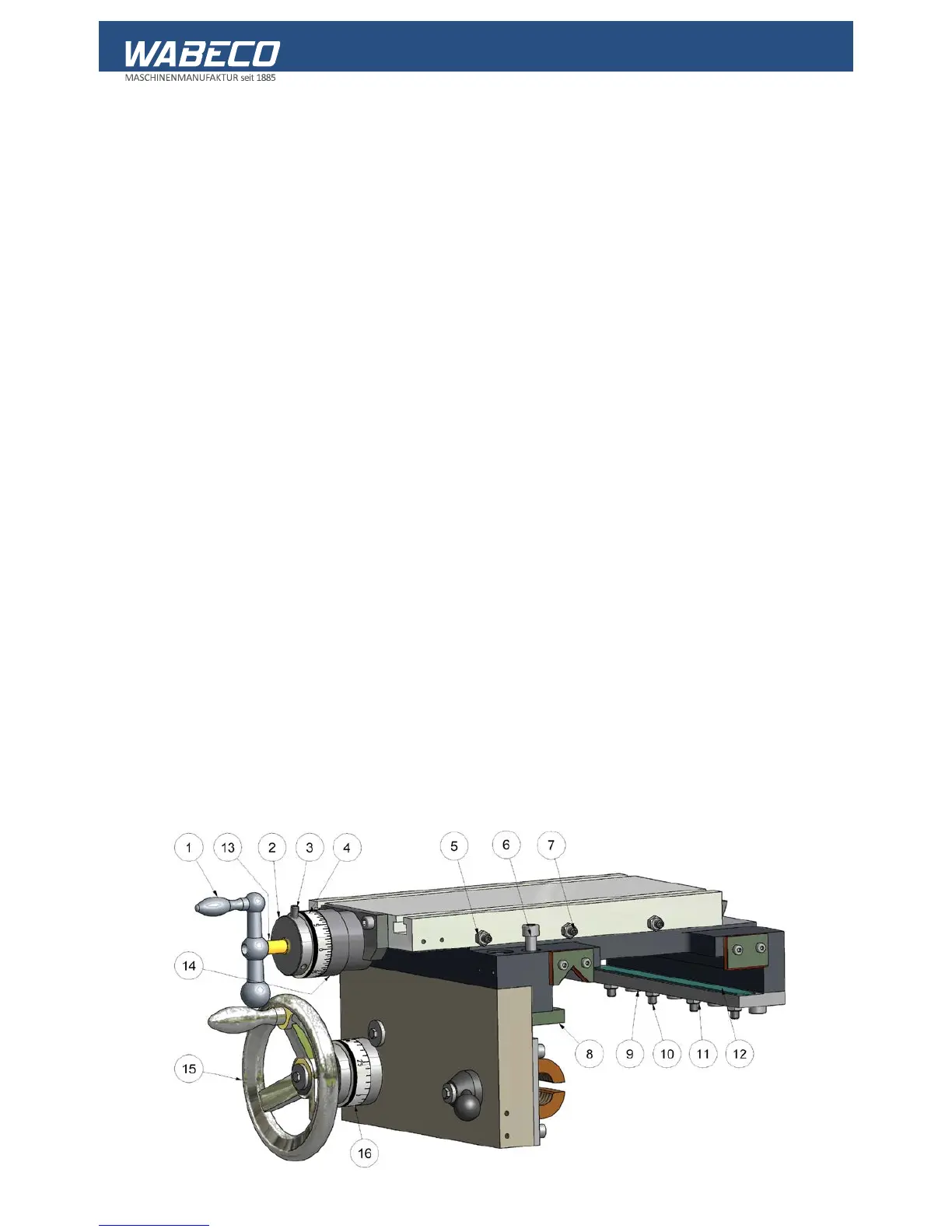

12. Tool skid – Transverse skid

The tool skid is positioned, at the front, on a prismatic guide and, at the rear, on a flat guide. The skid

is held onto the bed from below with the guide bar (9) and can be set to without play using the setting

bar (12).

If adjustment to the setting bar (12) is required, please proceed as follows:

1. Undo the hexagonal nuts (11)

2. Using an Allen key, tighten the threaded pins (10) in such a way that the skid is still able to move

easily.

3. After setting, tighten the hexagonal nuts (11) back up again

Clamping for face turning and cutting work.

Use the Allen head screw (6) to clamp the clamping piece (8) against the underside of the prismatic

guide. The tool skid can no longer be moved in the longitudinal direction.

The dovetail guide of the transverse skid can be adjusted.

If adjustment is required, please proceed as follows:

1. Undo the hexagonal nuts (5)

2. Using an Allen key, tighten the threaded pins (7) in such a way that the skid can still be moved

easily using the ball crank (1).

3. After adjustment, tighten the hexagonal nuts (5) back up again

Any axial play of the spindle (13) in the spindle bearing (14) that may occur, can be adjusted.

If adjustment is required, please proceed as follows:

1. Undo the threaded pins (3)

2. Rotate the dial (2) clockwise in such a way that no axial play remains

3. Tighten the threaded pins (3) back up again

4. After adjustment, the spindle (13) should still be easy to turn

Loading...

Loading...