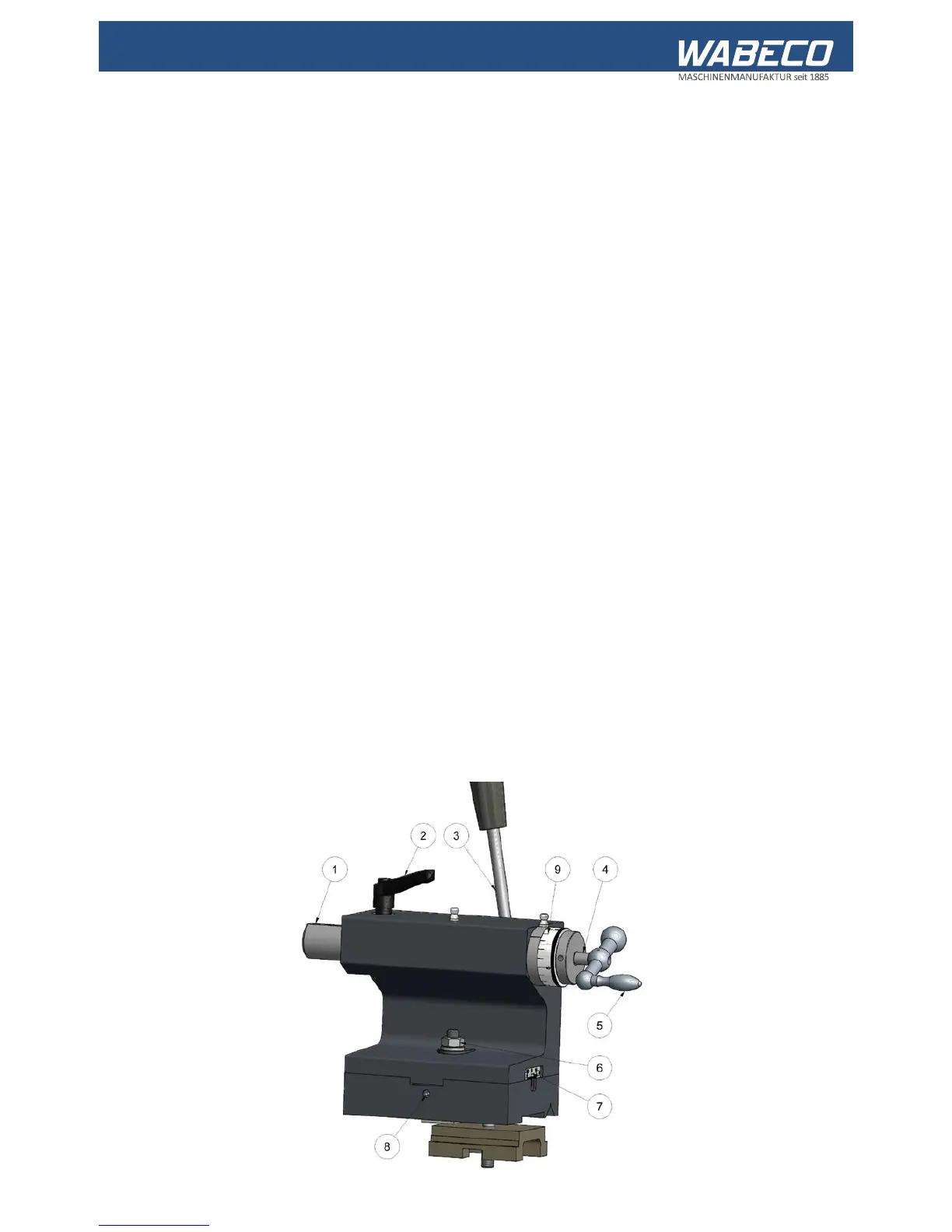

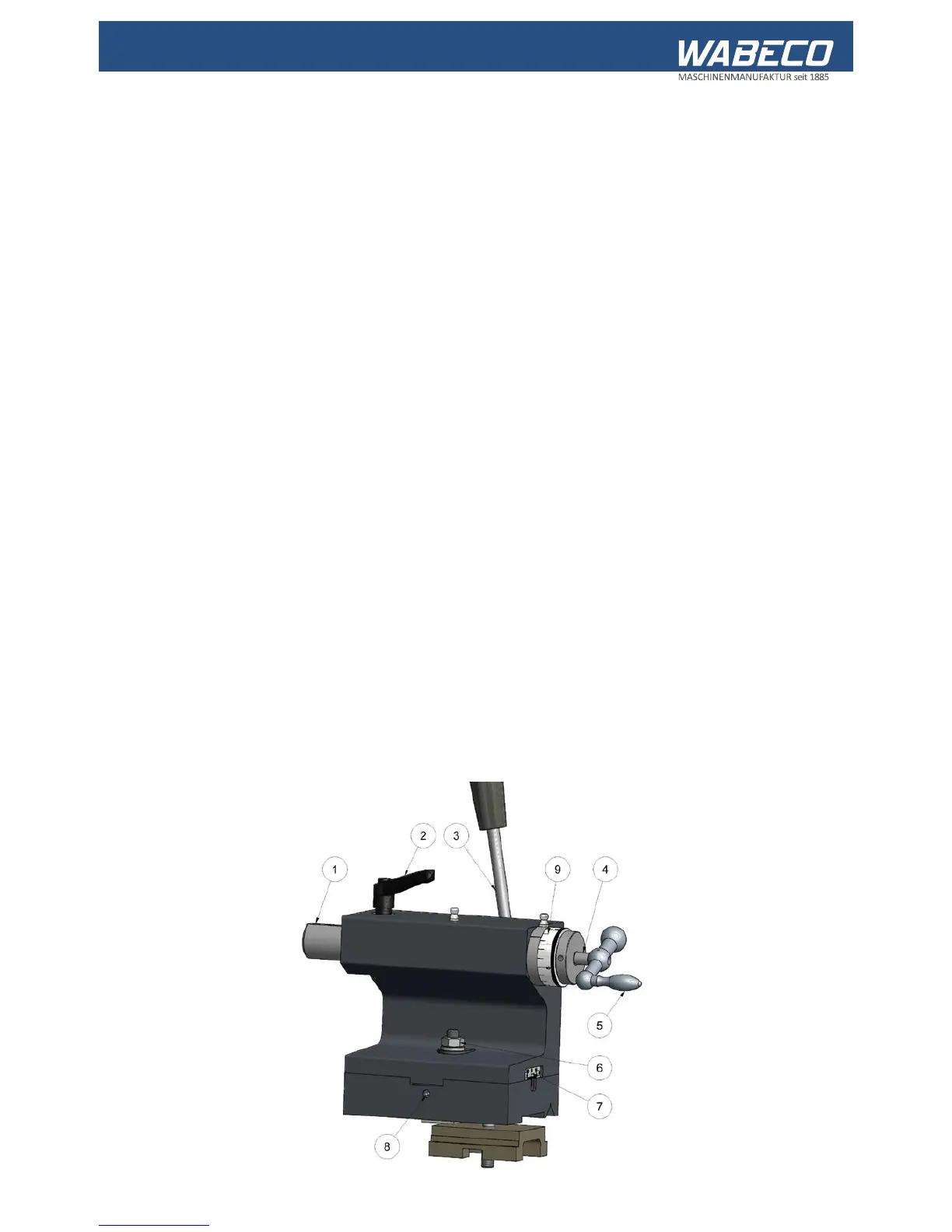

14. Tailstock

■ The tailstock can be moved on the lathe bed.

■ By moving the clamping lever (3), the tailstock can easily be secured in any position.

■ The tailstock is made up of an upper and lower section.

■ The upper section can be moved by a maximum of ±10 mm in order to turn long, slim tapers.

To do this, proceed as follows:

1. Undo the hexagonal nut (6)

2. With the help of both threaded pins (8), slide the upper section into the required direction

■ The central position of the tailstock is shown by the scale mark (7)

■ Turn a sample to see whether the work piece is cylindrical, correct the tailstock setting if necessary

Tailstock sleeve

■ The solid tailstock sleeve has a millimetre scale.

To read off the distance of travel of the tailstock sleeve, there is a scale ring (9)

■ One mark on the scale corresponds to an adjustment of 0.1 mm.

■ One turn of the ball crank (5) corresponds to a distance of 2 mm.

■ Centre point, drill or drill chucks are automatically ejected when turning back.

Tool holder

■ There is an inside cone MK 2 which is designed to hold tools and is incorporated in the sleeve

(1).

■ Tightening the clamping lever (2) ensures that the sleeve may be easily clamped in any position.

■ The sleeve is moved axially by the hand crank (5) by way of the threaded spindle (4).

Loading...

Loading...