8. Lubrication of the machine

The lubrication process:

■ Reduces wear and friction

■ Increases the lifetime

■ Protects metal surfaces from corrosion

We recommend:

■ A class 2NLGI multi-purpose grease for lubrication

■ A lubrication oil with a viscosity of 100 mm

2

/s for oiling

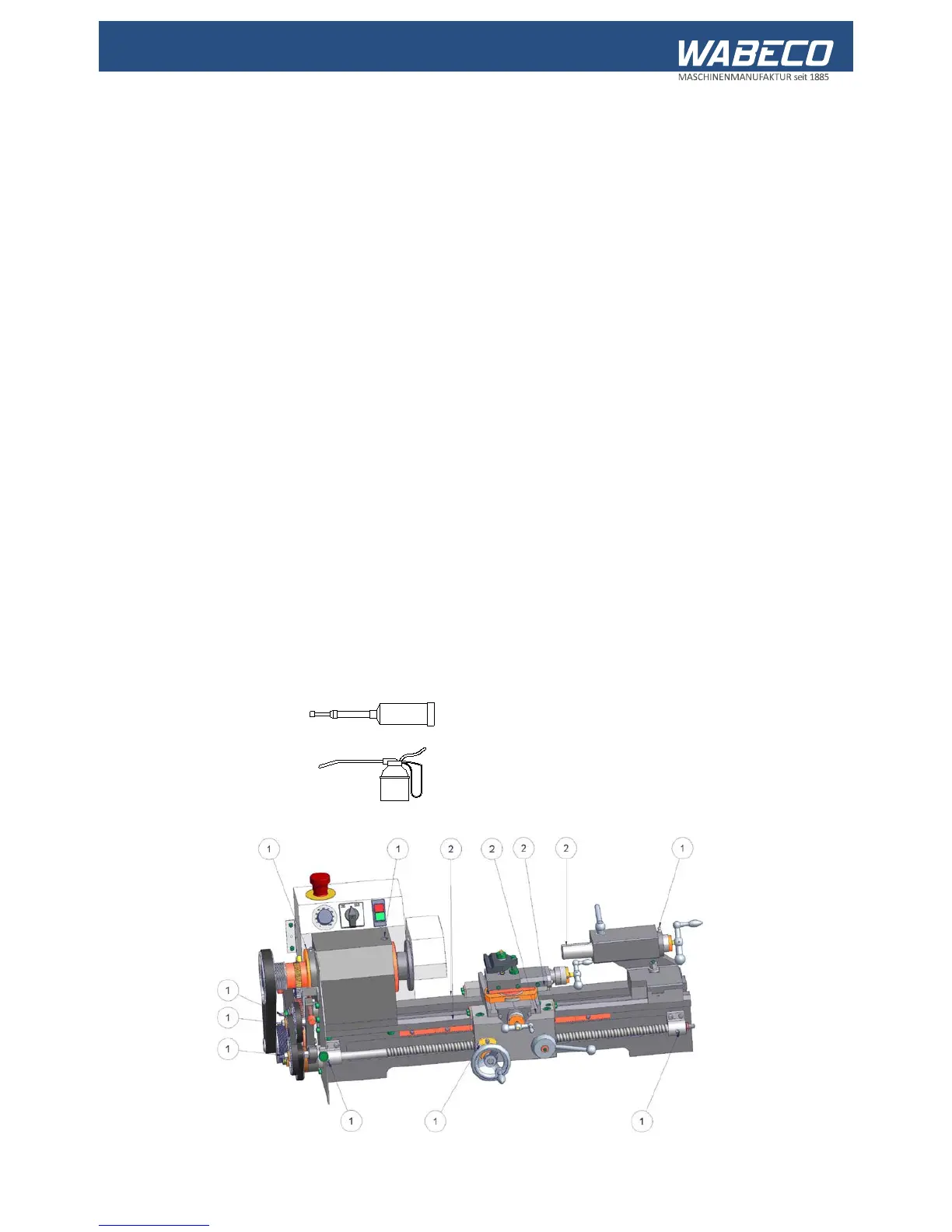

The lathe is to be lubricated every 8 hours of operation in accordance with the lubrication plan. The

lubrication points.

■ Bed guide

■ Dovetail guide, transverse skid

■ Tailstock sleeve

Are lubricated with the help of an oil can and an ordinary lubrication oil by moving the skid or sleeve

backwards and forwards.

All other lubrication points are lubricated with a grease press at the designated lubrication nipples.

The spindle bearing does not need to be lubricated since the ball bearings have a closed

construction form and the bearings have been supplied at the factory with sufficient grease for the

lifetime of the machine.

Loading...

Loading...