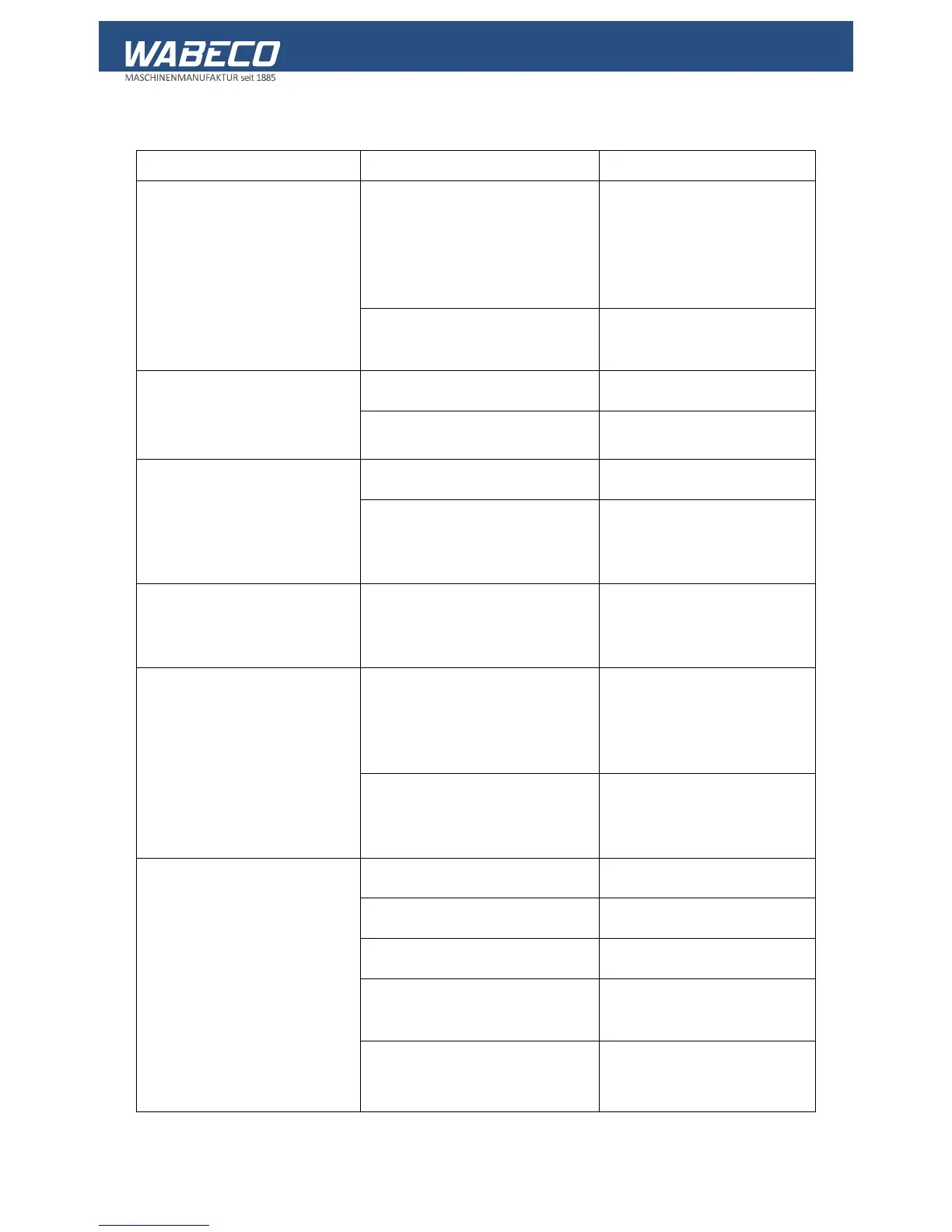

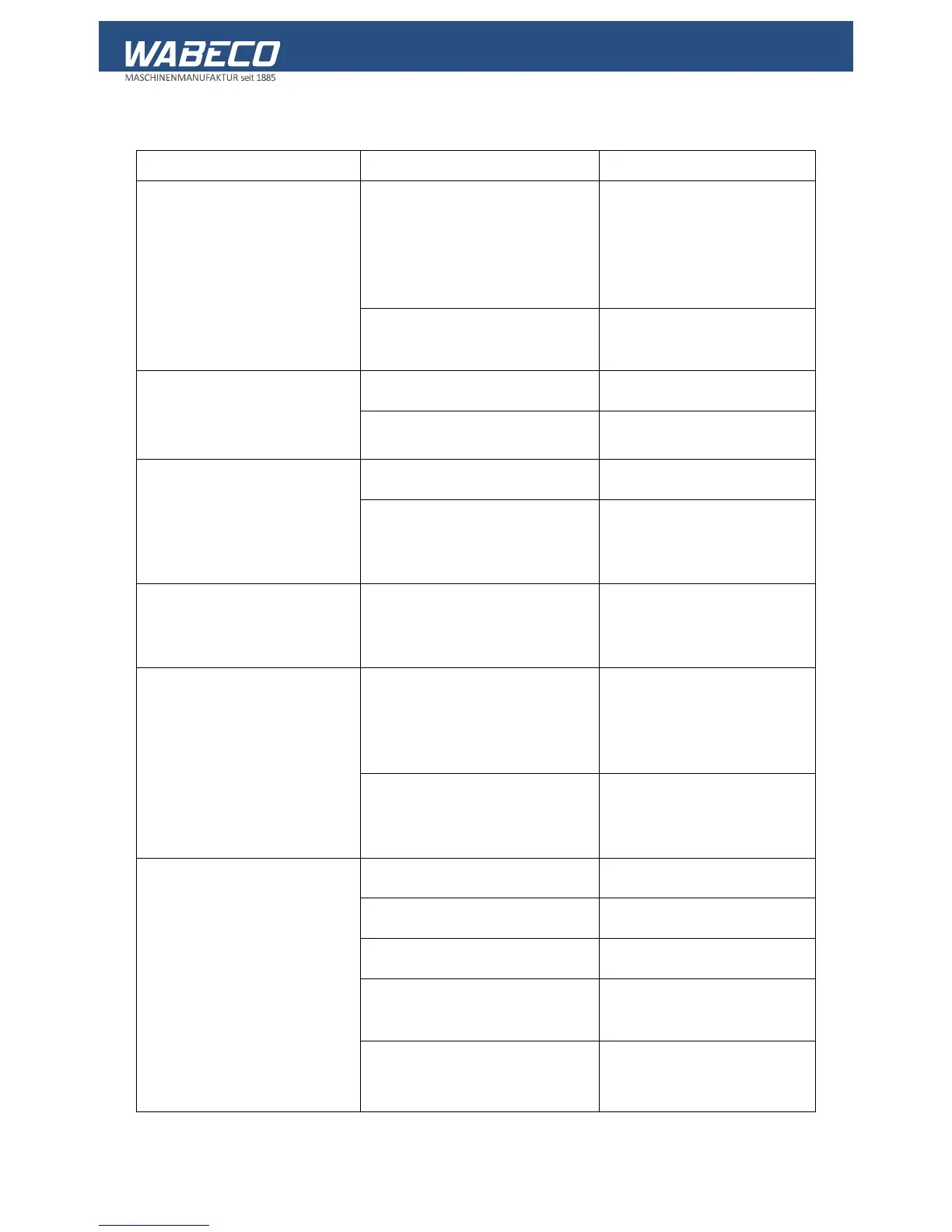

16. Operational faults and the elimination of such

Operational faults Possible cause Remedy

The drive motor (1.4 kW)

experiences "skips" during

operation

Carbon brushes and collector of

the drive motor are contaminated

Clean the carbon brushes and

collector of the drive motor

with a piece of coarse

sandpaper

(See "Maintenance" section)

Carbon brushes are worn Replace carbon brushes with

new ones

Tool skid cannot be moved or

can only be moved with

considerable force

Clamping of the tool skid is on Open the clamping

Guide play is set too narrowly Adapt the guide play

Transverse or longitudinal skid

cannot be moved or can only

be moved with considerable

force

Guide play is set too narrowly Adapt the guide play

Play of the trapezoidal-threaded

nut is set too narrowly (only

transverse skid)

Adapt the play of the

trapezoidal-threaded nut

Rust on work pieces of machine

parts when using coolant

lubrication

Wrong coolant set Check the mixing ratio of the

coolant and correct if required

(never cool with water alone!)

Tool holder cannot be inserted

into the main spindle (reducing

sleeve of the main spindle)

An incorrect tool taper of the tool

holder has been used in

combination with the reducing

sleeve

Only use the appropriate tool

holders for the machine

Inner cone of the reducing sleeve

or outer cone of the tool holder is

contaminated

Clean the relevant cone

Tool overheated Revolutions too high Reduce the revolutions

Feed too high Reduce the feed

Working without coolant Use coolant

Insufficient coolant feed at the

cutting edge

Align the coolant hose

correctly

Tool blunt

Sharpen tool or use a new tool

Loading...

Loading...