1

WEILER E1650 REMIXING TRANSFER VEHICLE

5-20

Maintenance

5

Maintenance Procedures

Storage Conveyor Chain - Adjust Tension/Uneven Sag

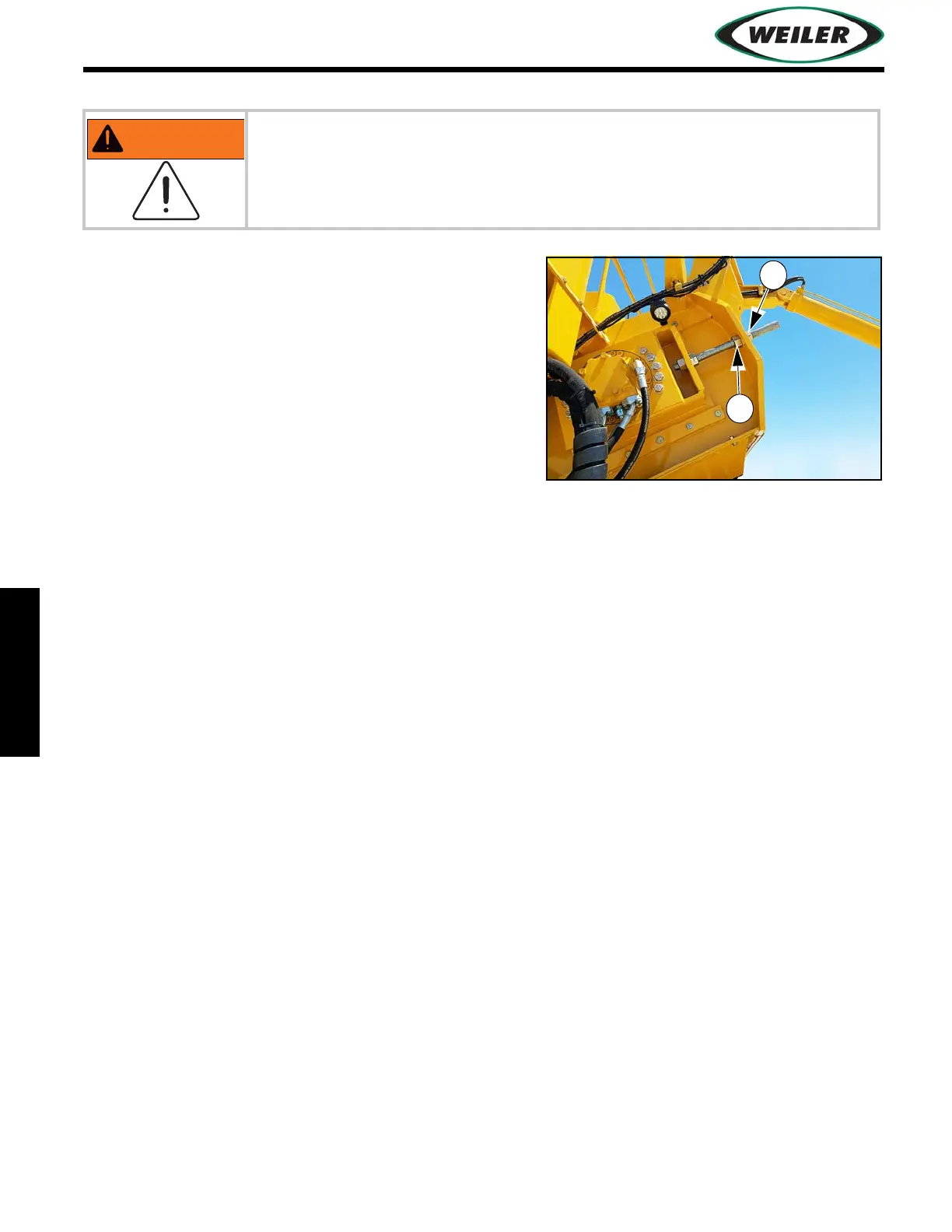

1. With engine off and ignition key removed, adjust

chain until bottom of chain slat is 2" (51 mm) at

measurement position shown in detail view B,

5-19.

Adjust both sides of chain until chain sag is even

from side to side, +/- 1/4" (6 mm).

•To tighten chain, loosen nut (1), adjust nut (2), then

tighten nut (1).

•To loosen chain, loosen nut (2), adjust nut (1), then

tighten nut (2).

2. Clean material off of cleanout door and sealing edges to allow door to close tightly.

3. Start engine. Close and latch cleanout door. Verify door is fully closed. Turn engine off.

Chain Checklist

Check chain for:

(1) Elongation Due to Joint Wear - Chain is worn when it has lengthened 5%.

Elevator Conveyor chain pitch - 4.25” (108 mm).

............................................ 10 links x 4.25” (108 mm) pitch + 5% wear = 44.63” (1134 mm).

Discharge Conveyor chain pitch - 3.25” (83 mm).

............................................ 10 links x 3.25” (83 mm) pitch + 5% wear = 34.13” (867 mm).

(2) Stiff Joints - Drag chain rollers packed with debris which leads to a torsion failure of the pins.

(3) Sidebar Wear - Inside of links worn from sides of sprocket teeth indicating misalignment.

(4) Sidebar Wear - Check drag chain sidebars on bottom side to see if they are worn (or bent) from

contacting idler roller flanges.

(5) Roller Wear - Rollers should be polished where the sprocket tooth touches, not worn or gouged.

Worn or gouged barrels could indicate sprocket problems such as hooked teeth.

(6) Roller Wear - I.D.’s of rollers are worn if there is excessive play or misalignment.

(7) Obstructions - Check for any liner wear plates or joints that are loose or out of line which will

catch the chain slats as they pass by.

Slip and fall hazard.

Adjust chain tension while standing on a securely placed ladder. Never

climb onto top of machine to access adjusters.

Loading...

Loading...