CAUTION Observe screw torque specifications, especially with screws

that secure directly into plastic standoffs.

CAUTION To avoid mismatching screws and holes, keep the screws for

each piece with that piece as you remove modules and circuit assemblies.

It is possible to mistakenly install machine screws in locations intended for

plastite screws. Plastite screws have a Torx-pan head.

Required tools and equipment

• Phillips #1 screwdriver

• T-10 Torx screwdriver

• 3mm hex key

Torque value table

Use this table to determine how much torque to apply to screws by type and location

when reassembling the device.

Description Torque specification Bit type Where used

SCR,4-20X.31 PLASTITE PH TORX

4.5 +/-0.5 in-lbs

Torx Chassis and SpO2 Insert to Main

CSM PCA. Radio/Bluetooth PCBA

to Chassis

SCREW 4-40 .250 PAN PHILLIPS

STEEL ZINC

4.5 +/-0.5 in-lbs

Phillips SpO2 boards

SCREW, M2 X 6 INTERNAL TOOTH

SEMS PHP

2.5 +/-0.25 in-lbs

Phillips Radio PCA to Radio Interface PCA

SCREW, M4 X 10 PAN HEAD W

NYLOC

7.5 +/-0.5 in-lbs

Phillips Front to Back Housing and

Temperature Module/Dock

SCR, M4 PAN HD, PHD, SHOULDER

4.5 +/-0.5 in-lbs

Phillips Battery Door

44

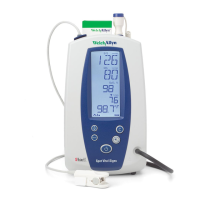

Disassembly and repair Connex

®

Spot Monitor

Loading...

Loading...