FUEL SYSTEM

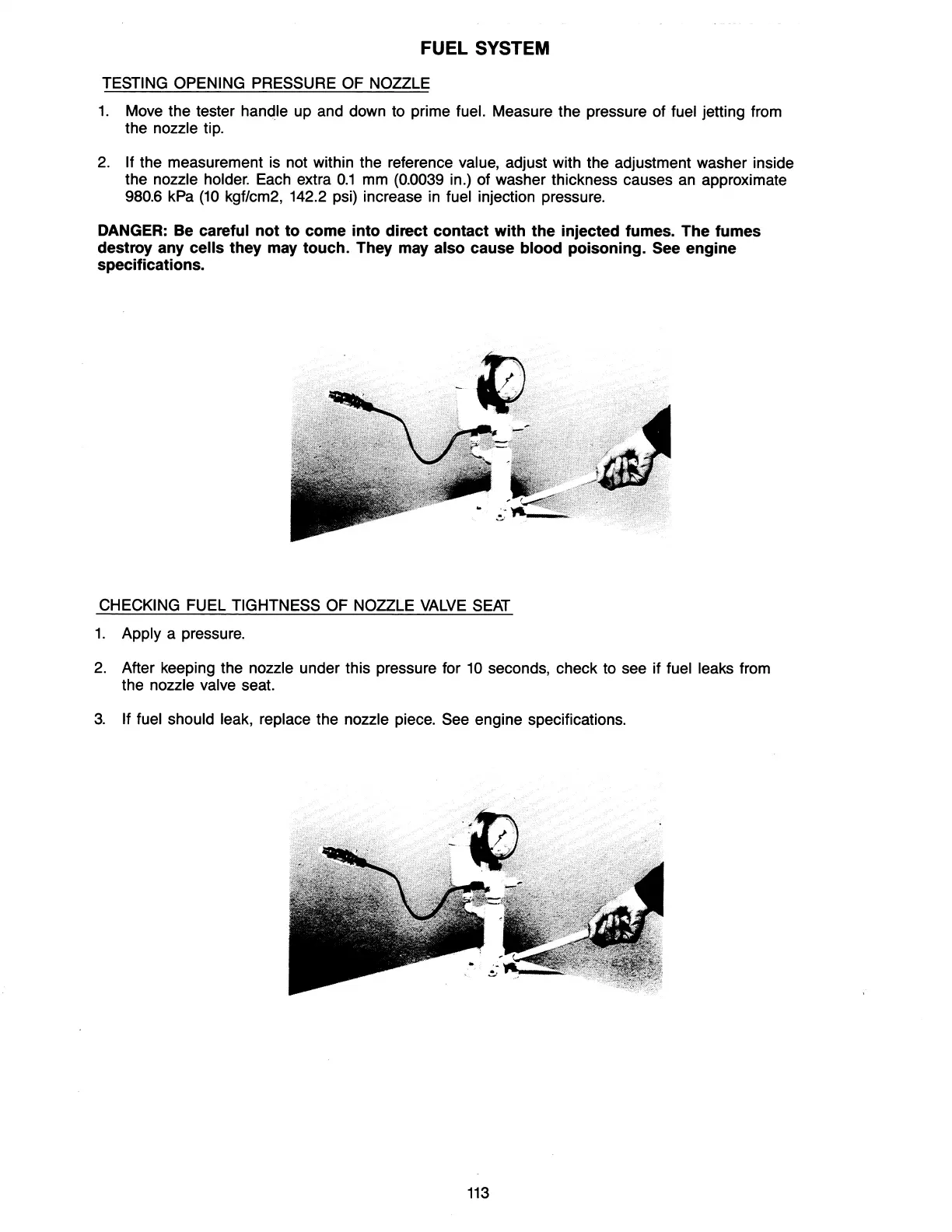

TESTING OPENING PRESSURE OF NOZZLE

1.

Move the tester hanctle up and down to prime fuel. Measure the pressure of fuel jetting from

the

nozzle tip.

2.

If the measurement is not within the reference value, adjust with the adjustment washer inside

the

nozzle holder. Each extra

0.1

mm (0.0039 in.) of washer thickness causes

an

approximate

980.6

kPa

(10

kgf/cm2, 142.2 psi) increase in fuel injection pressure.

DANGER: Be careful

not

to

come into direct contact with the injected fumes. The fumes

destroy any

cells they may touch. They may also cause blood poisoning. See engine

specifications.

CHECKING FUEL TIGHTNESS OF NOZZLE

VALVE

SEAT

1.

Apply a pressure.

2.

After keeping the nozzle under this pressure for

10

seconds, check to see if fuel leaks from

the

nozzle valve seat.

3.

If fuel should leak, replace the nozzle piece. See engine specifications.

113

Loading...

Loading...