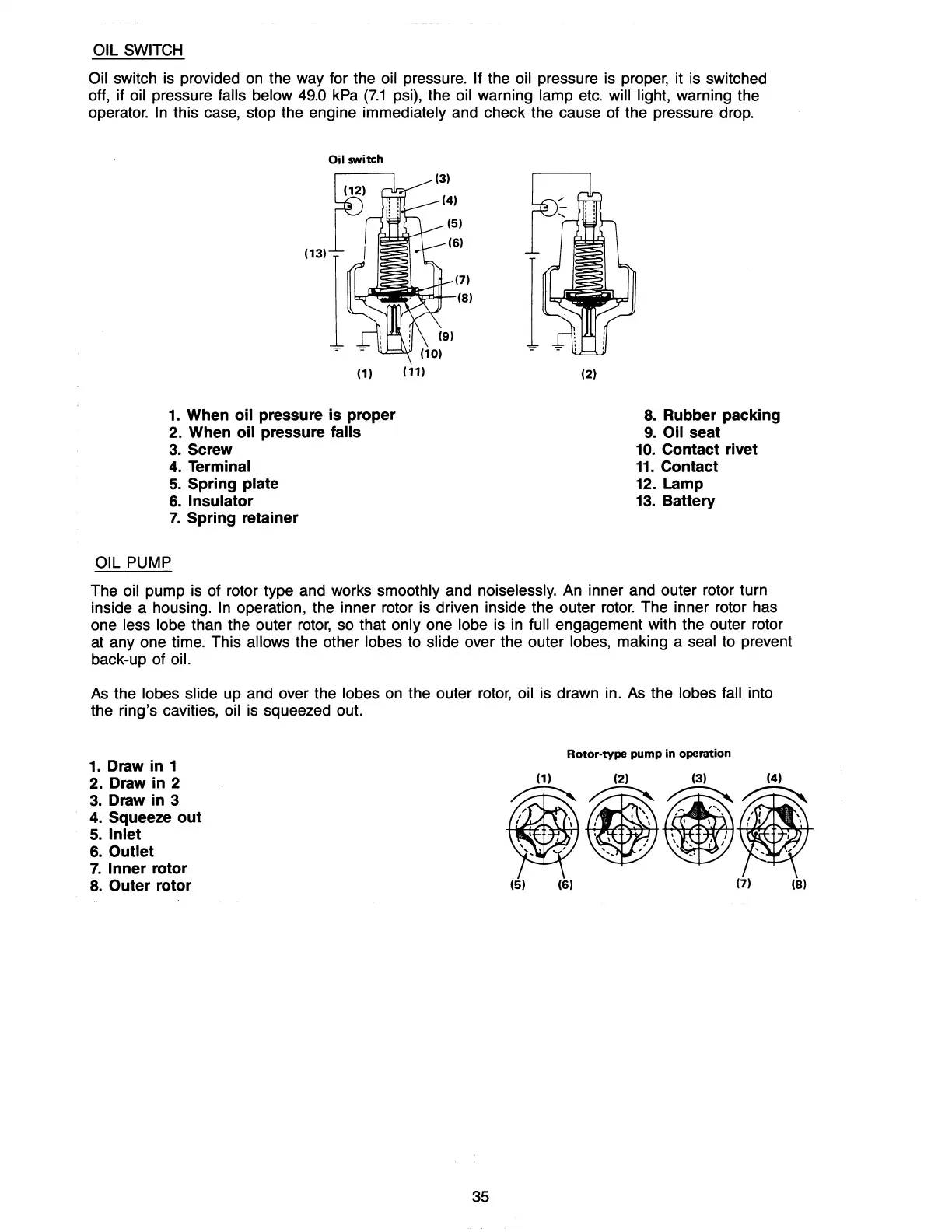

OIL

SWITCH

Oil switch

is

provided

on

the way for the oil pressure. If the oil pressure is

proper,

it

is

switched

off, if oil pressure

falls below

49.0

kPa

(7.1

psi), the oil warning lamp

etc.

will light, warning the

operator.

In

this

case,

stop the engine immediately and check the cause of the pressure drop.

Oil

switch

(1)

1. When

oil

pressure

is

proper

2. When oil pressure falls

3. Screw

4. Terminal

5. Spring plate

6.

Insulator

7.

Spring retainer

OIL PUMP

(1)

_'t=l.,jj..-

(8)

(11)

(2)

8. Rubber packing

9.

Oil seat

10. Contact rivet

11. Contact

12. Lamp

13. Battery

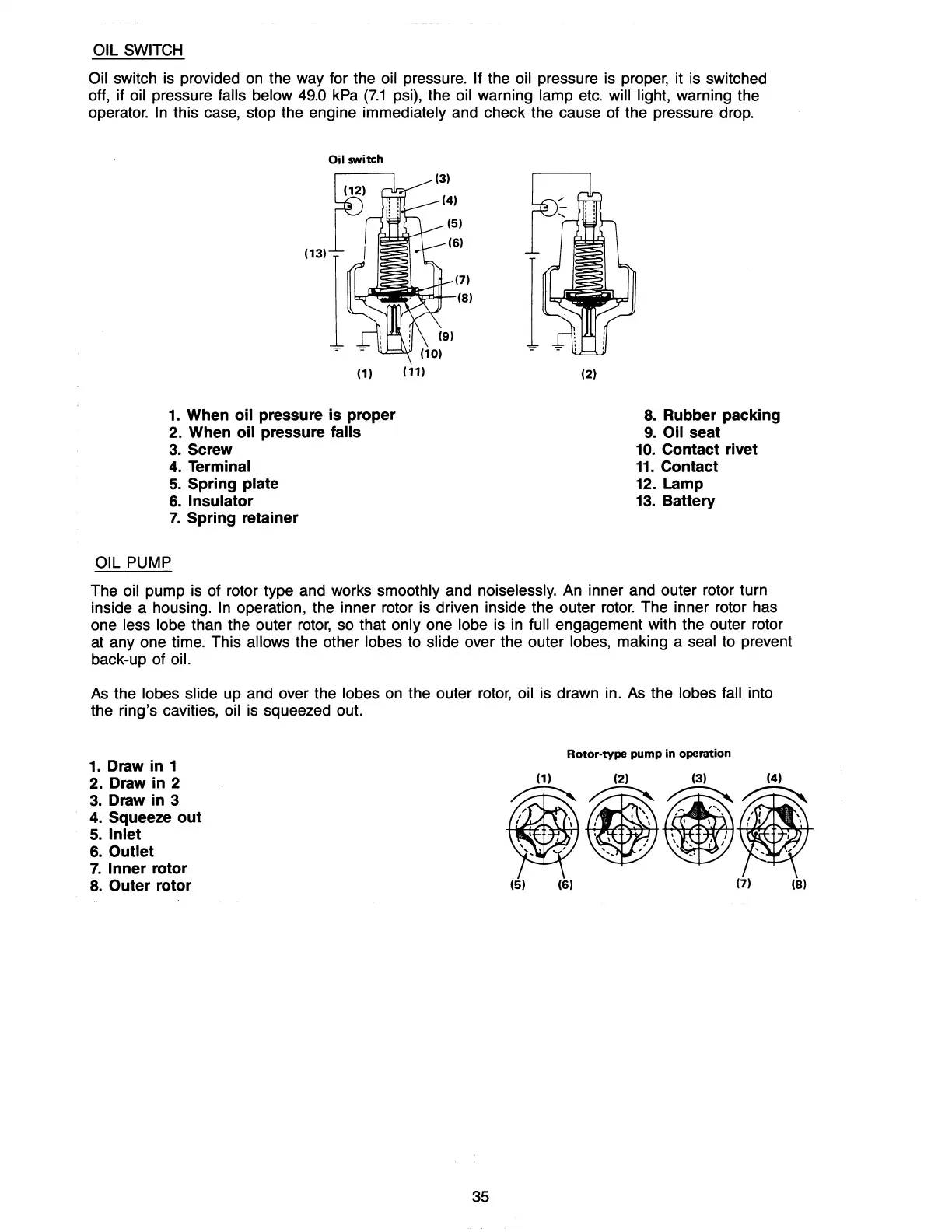

The oil pump

is

of rotor type and works smoothly and noiselessly.

An

inner and outer rotor turn

inside a housing.

In

operation, the inner rotor is driven inside the outer

rotor.

The inner rotor

has

one less lobe than the outer

rotor,

so

that only one lobe

is

in

full engagement with the outer rotor

at

anyone

time. This allows the other lobes

to

slide over the outer lobes, making a seal

to

prevent

back-up of

oil.

As the lobes slide up and over the lobes

on

the outer

rotor,

oil is drawn in. As the lobes fall into

the ring's cavities, oil

is

squeezed out.

1.

Draw in 1

Rotor-type

pump

in operation

2. Draw in 2

3.

Draw in 3

4.

Squeeze

out

5.

Inlet

6.

Outlet

7.

Inner rotor

8.

Outer rotor

35

Loading...

Loading...