BELT

INSTALLATION, ALIGNMENT & TENSIONING

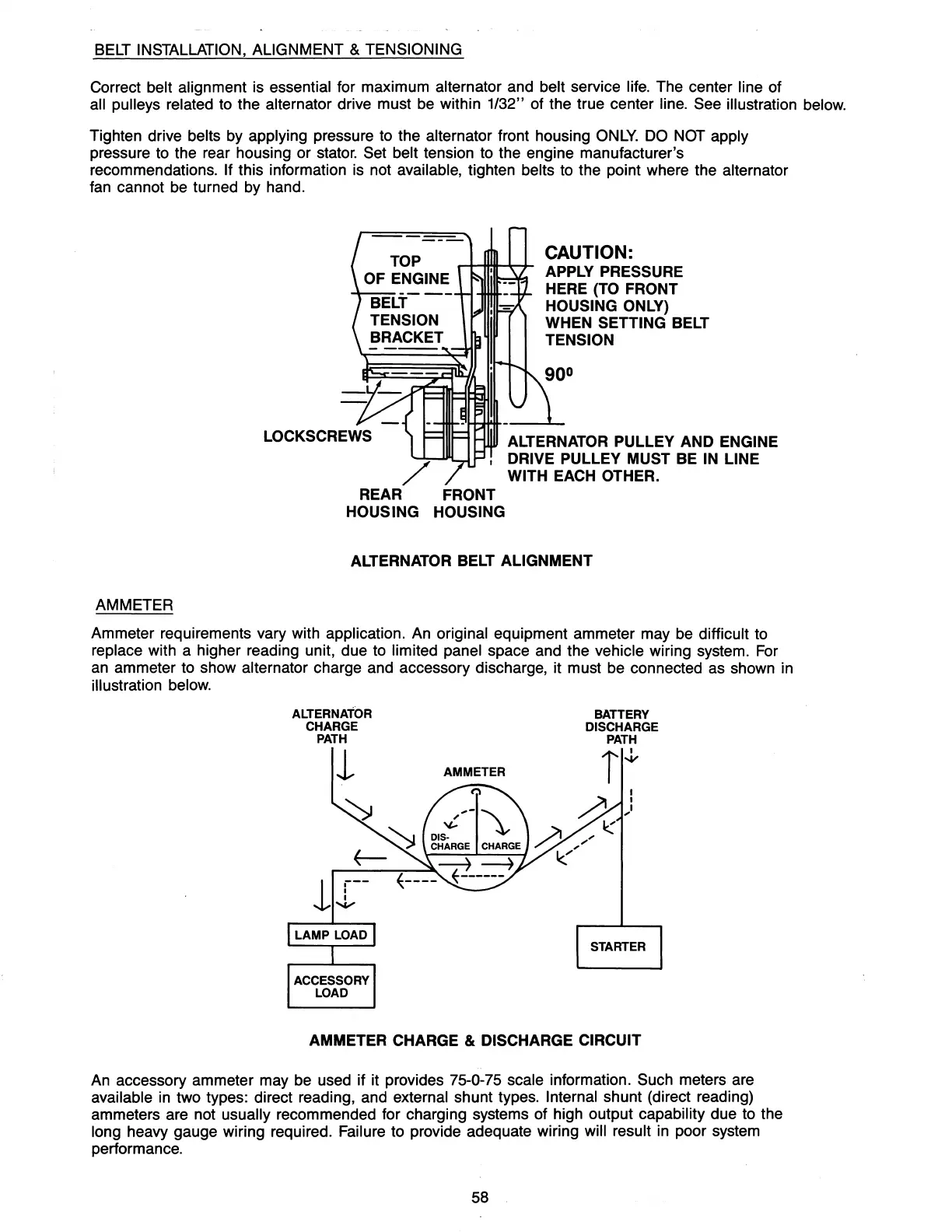

Correct belt alignment is essential for maximum alternator and belt service life. The center line of

all pulleys related to the alternator drive must be within 1/32" of the true center line. See illustration below.

Tighten drive belts by applying pressure to the alternator front housing

ONLY.

DO NOT apply

pressure to the rear housing or stator. Set belt tension to the engine manufacturer's

recommendations.

If this information is not available, tighten belts to the point where the alternator

fan cannot be turned by hand.

AMMETER

CAUTION:

APPLY PRESSURE

HERE (TO FRONT

HOUSING ONLY)

WHEN SETTING BELT

TENSION

ALTERNATOR PULLEY AND ENGINE

/

I DRIVE PULLEY MUST BE IN LINE

WITH

EACH OTHER.

REAR FRONT

HOUSING HOUSING

ALTERNATOR BELT ALIGNMENT

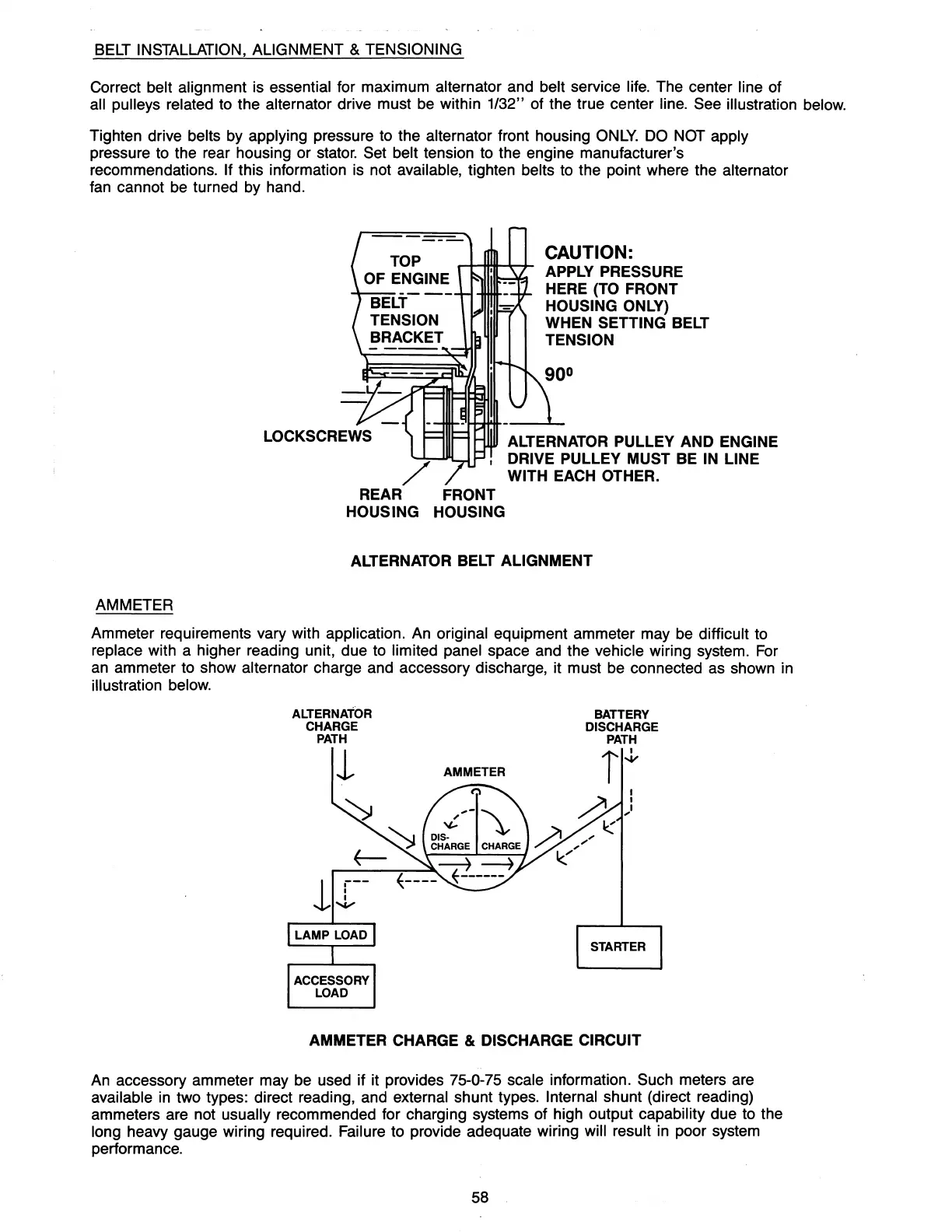

Ammeter requirements vary with application. An original equipment ammeter may be difficult to

replace with a higher reading unit, due to limited panel space and the vehicle wiring system. For

an ammeter to show

alternator charge and accessory discharge, it must be connected as shown in

illustration

below.

ALTERNATOR

CHARGE

PATH

1

~

AMMETER

BATTERY

DISCHARGE

PATH

T~

AMMETER CHARGE & DISCHARGE CIRCUIT

An

accessory ammeter may be used

if

it provides 75-0-75 scale information. Such meters are

available

in

two types: direct reading, and external shunt types. Internal shunt (direct reading)

ammeters are not

usually recommended for charging systems of high output capability due to the

long heavy gauge wiring required. Failure to provide adequate wiring will result in poor system

performance.

58

Loading...

Loading...