Operation0510−1/A1

Winterthur Gas & Diesel Ltd.

2/ 2

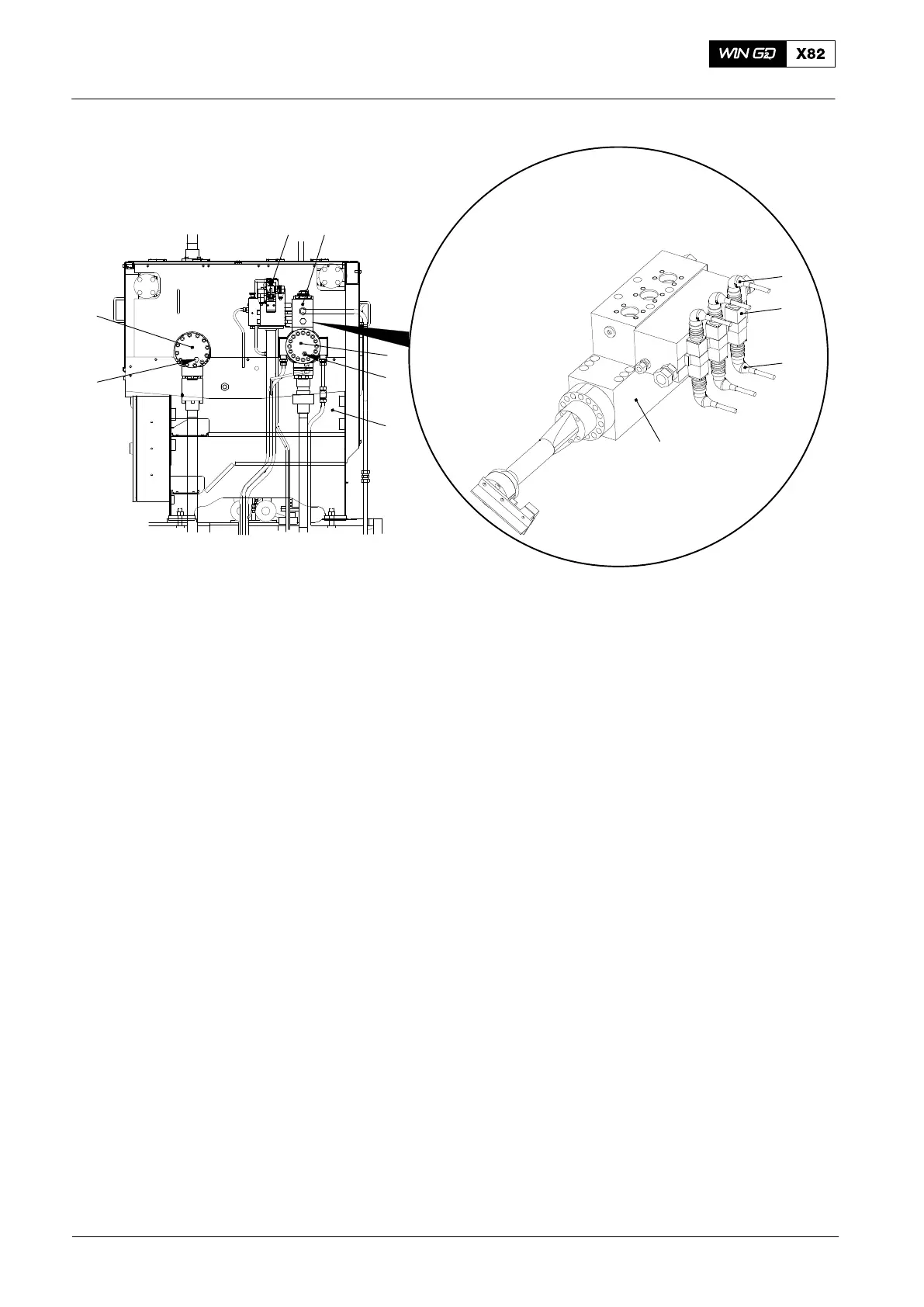

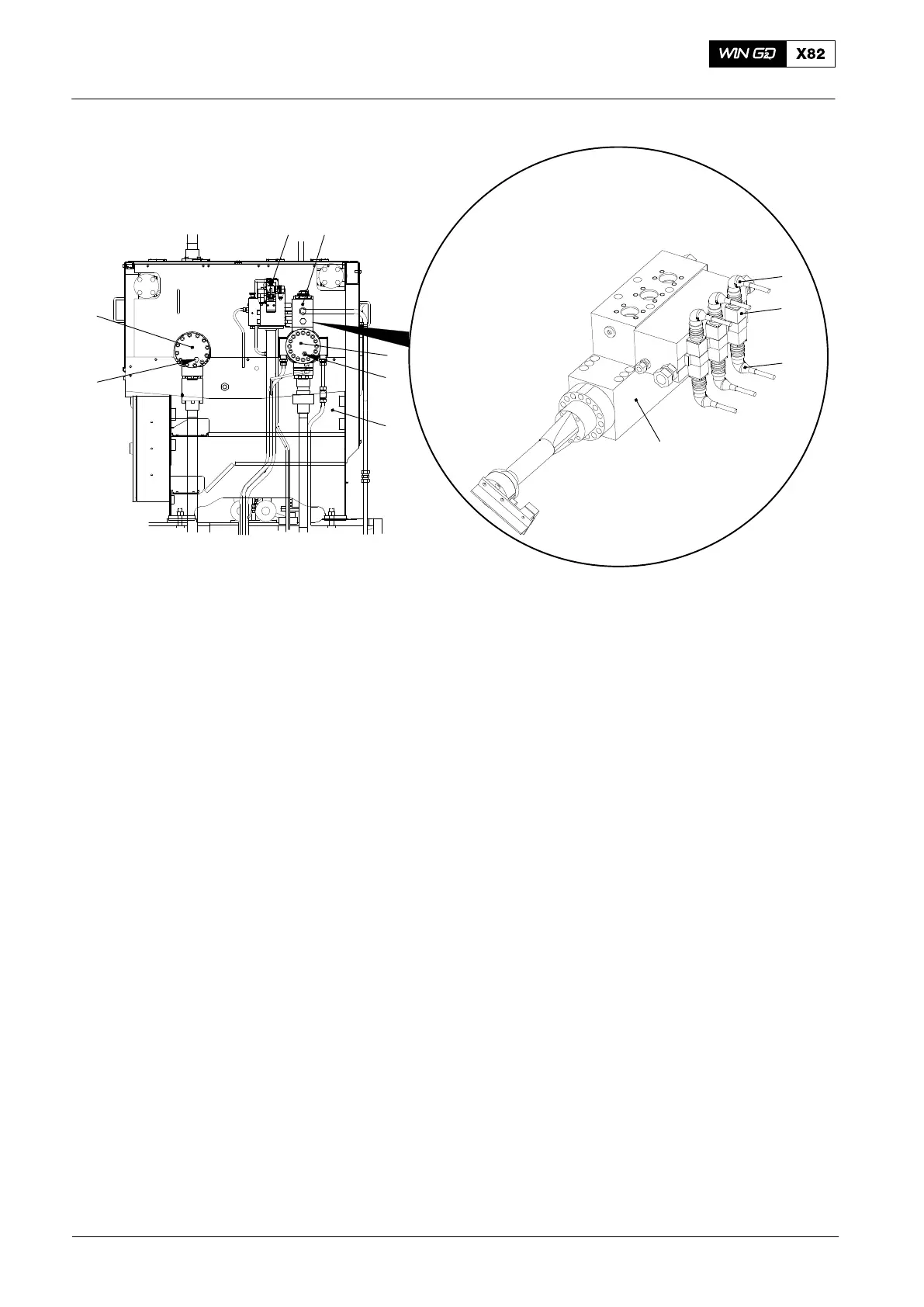

WCH01184

DRIVING END

1

9

6

43

2

5

8

7

8

WCH01182

3

Fig. 1: Rail unit and injection control unit

1 Fuel rail 3.05 6 Drain screw 3.82

2 Servo oil rail 4.11 7 Rail valve 3.76

3 Injection control unit 3.02 8 Electrical connection

4 Fuel pressure control valve 3.06 9 Rail unit

5 Drain screw 4.82

2.2 Replace the Defective Injection Pipe

Replace the defective injection pipe as soon as possible.

Note: You can use the screw-in unions on the ICU fuel leakage pipe to find a

defective injection pipe that leaks (see 8019−1 Fuel leakage system,

paragraph 4.3).

As a temporary procedure, do as follows:

1) Disconnect the two electrical connections (8) from the related rail valve (7) on the

injection control unit (3) to isolate the defective injection pipe.

Injection will continue to operate through the remaining injection pipes, but this makes

the injection time longer and releases an alarm Inj. time too long.

2) Stop the engine.

3) Replace defective injection pipe (see 8733−1 Fuel Pressure Piping in the

Maintenance Manual).

Operation with Injection Cut Out (One or More Cylinders)

2014

Loading...

Loading...