Maintenance2745−1/A1

RT-flex58T-D

Winterthur Gas & Diesel Ltd.

2/ 2

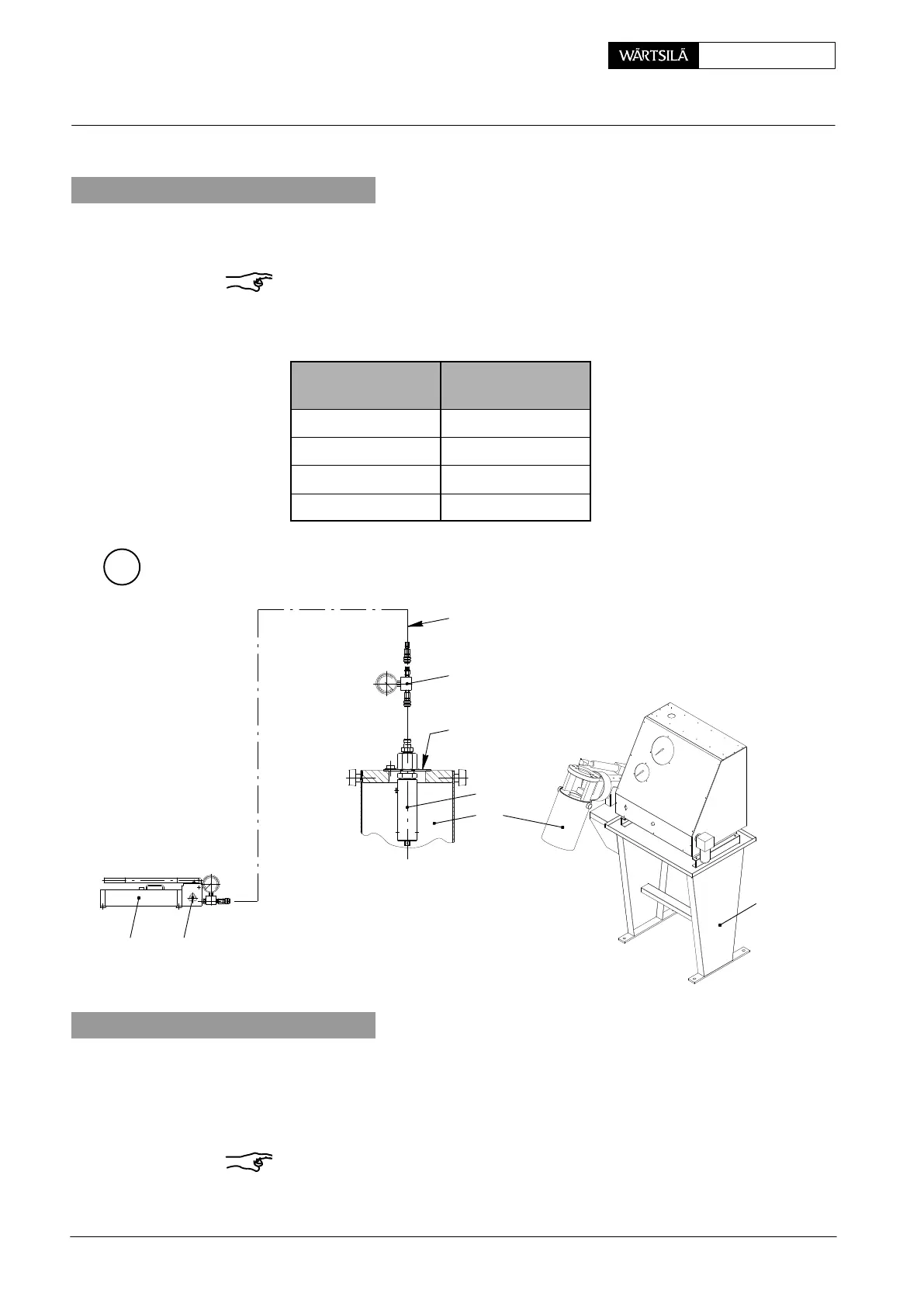

2. Checking blow-off pressure

For checking relief valve 2 use test bench 94272 and test & calibration fluid (see

specification in 2722−1) or a thin-bodied oil as test medium.

Remark: Pay attention to the manufacturer’s detailed instructions and working

specifications of the test bench.

If necessary, a relief valve must be replaced completely and set according to the

following table:

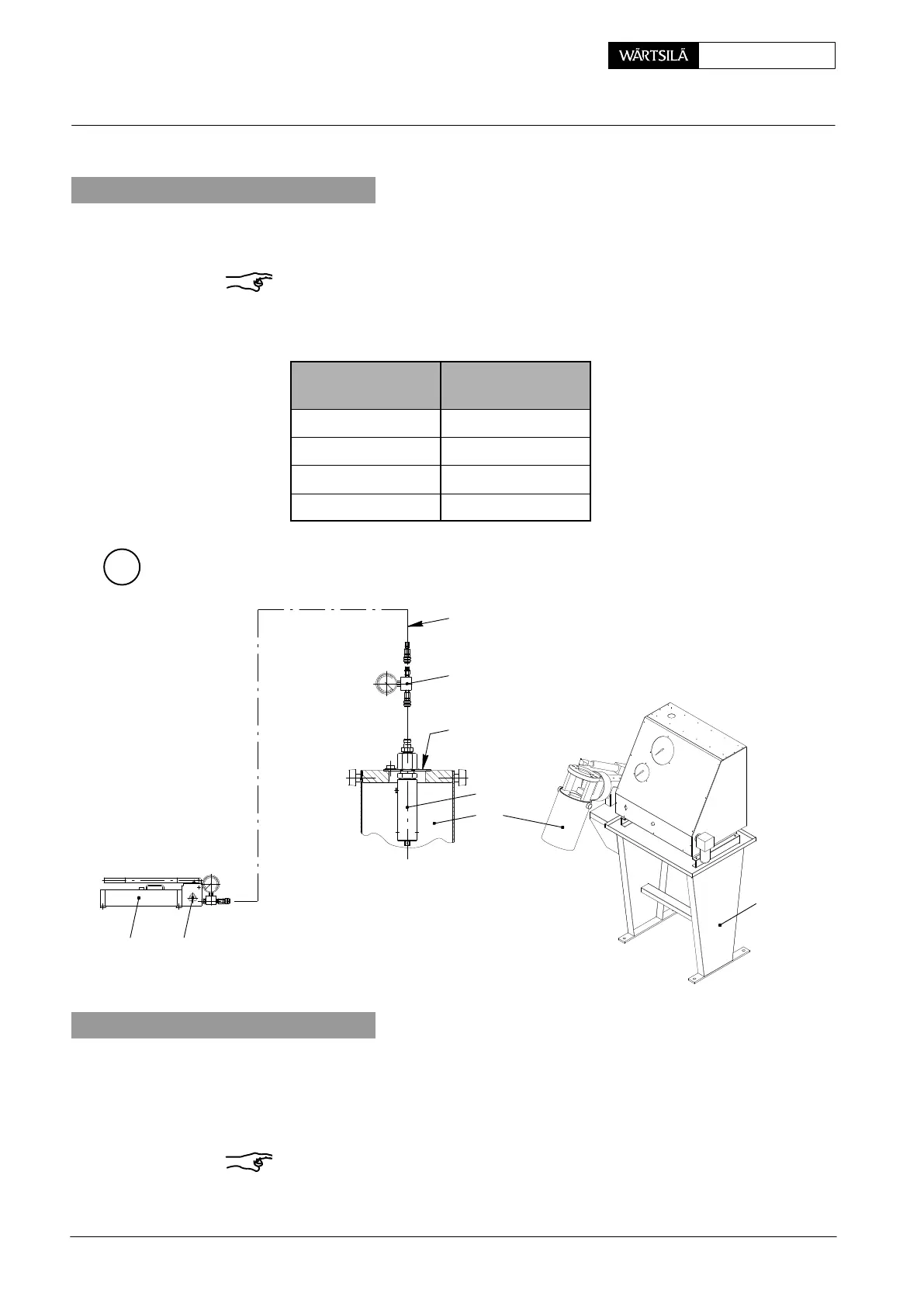

Firing pressure

[bar]

Blow-off pressure

[bar]

156−160 225

166−169 235

174−175 245

176−180 250

B

013.484/05

013.486/05

94935

94934A

94272

94931 EV

017.670/08

10

94272C

2

3. Fitting the relief valve

⇒ Apply Never-Seez NSBT-8 to the thread of relief valve 2 and fit it with new gas-

ket 7.

⇒ Always properly close indicator valve 3 so that no gas escapes and then

screw on its cap.

Remark: If indicator valves leak for a long period the seats will become damaged.

Early replacement of a leaking indicator valve will allow easy repair. All threads and

internal parts must also be smeared with Never-Seez NSBT-8.

Relief Valve: Checking Blow-off Pressure

2013

Loading...

Loading...