POWR

Power unit

5-39

6C13G11

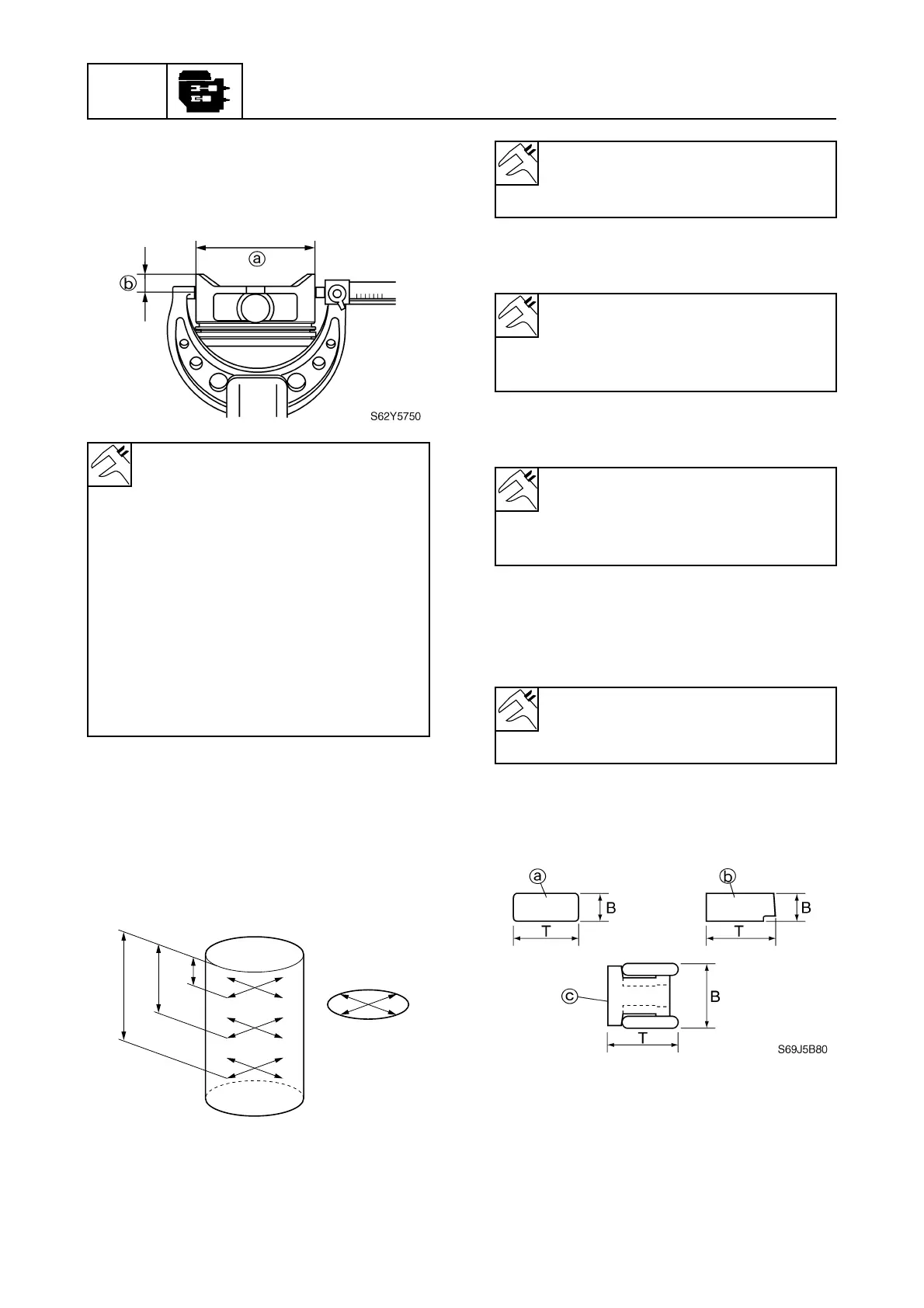

Checking the piston diameter

1. Measure the piston outside diameter at

the specified measuring point. Replace if

out of specification.

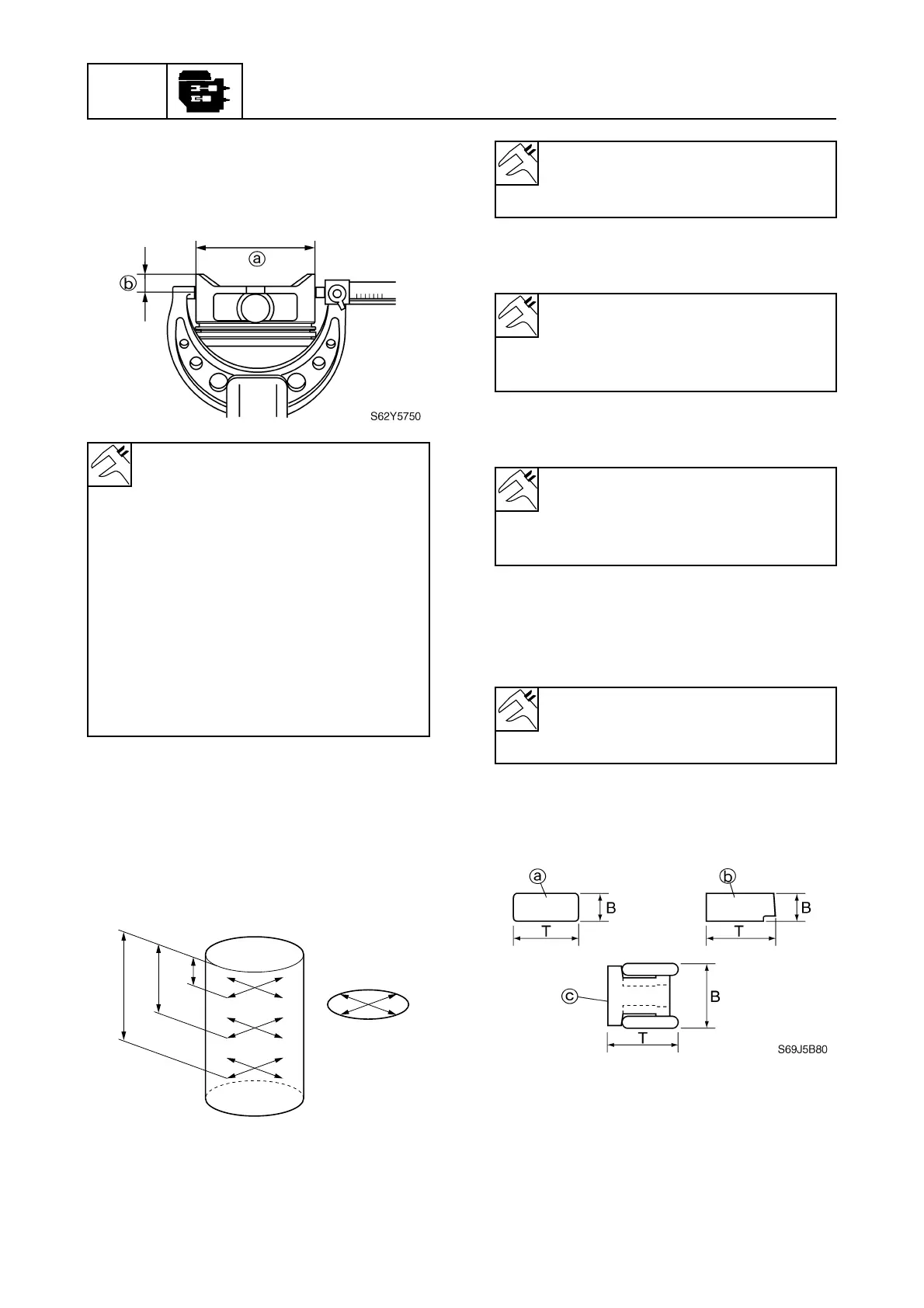

Checking the cylinder bore

1. Measure the cylinder bore (D

1

–D

6

) at

measuring points

a

,

b

, and

c

, and in

direction

d

(D

1

, D

3

, D

5

), which is parallel

to the crankshaft, and direction

e

(D

2

,

D

4

, D

6

), which is at a right angle to the

crankshaft.

a

20 mm (0.8 in)

b

40 mm (1.6 in)

c

70 mm (2.8 in)

2. Calculate the taper limit. Replace the cyl-

inder block if above specification.

3. Calculate the out-of-round limit. Replace

the cylinder block if above specification.

Checking the piston clearance

1. Replace the piston and piston rings as a

set or the cylinder block, or all parts if out

of specification.

Checking the piston rings

1. Check the piston ring dimensions of B

and T. Replace if out of specification.

Piston diameter

a

:

64.950–64.965 mm

(2.5571–2.5577 in)

Measuring point

b

:

5.0 mm (0.20 in) up from the

bottom of the piston skirt

Oversize piston diameter:

Oversize 1st:

65.200–65.215 mm

(2.5669–2.5675 in)

Oversize 2nd:

65.450–65.465 mm

(2.5768–2.5774 in)

S69J5B70

D

1

D

2

D

3

D

4

D

5

D

6

a

b

c

d

e

Cylinder bore (D

1

–D

6

):

65.000–65.015 mm

(2.5591–2.5596 in)

Taper limit:

D

1

–D

5

(direction

d

)

D

2

–D

6

(direction

e

)

0.08 mm (0.0032 in)

Out-of-round limit:

D

2

–D

1

(measuring point

a

)

D

6

–D

5

(measuring point

c

)

0.05 mm (0.0020 in)

Piston clearance:

0.035–0.065 mm

(0.0014–0.0026 in)

Loading...

Loading...