6C13G11

5-42

1

2

3

4

5

6

7

8

9

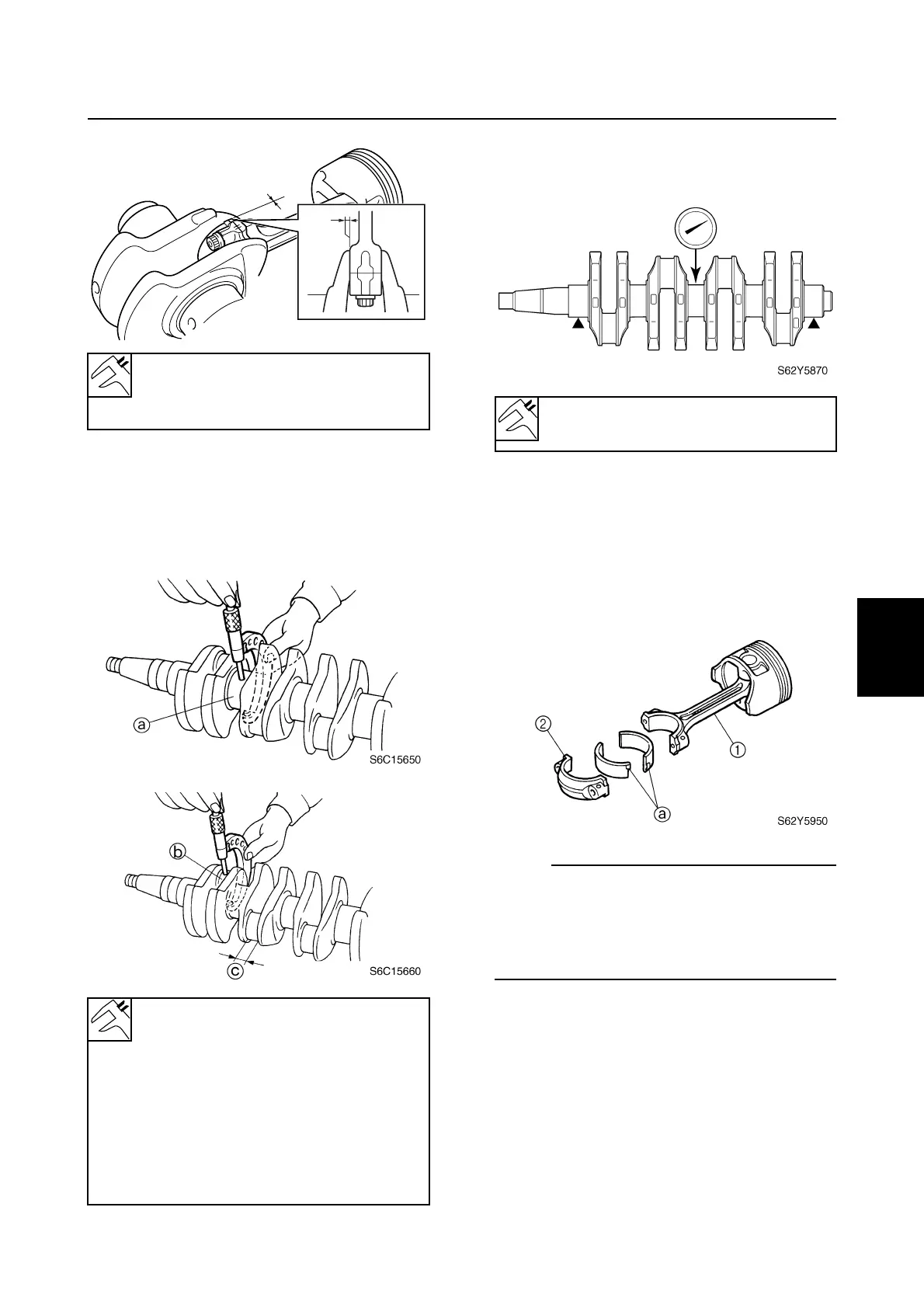

Checking the crankshaft

1. Measure the crankshaft journal diameter

a

, crankpin diameter

b

, and crankpin

width

c

. Replace the crankshaft if out of

specification.

2. Measure the crankshaft runout. Replace

the crankshaft if above specification.

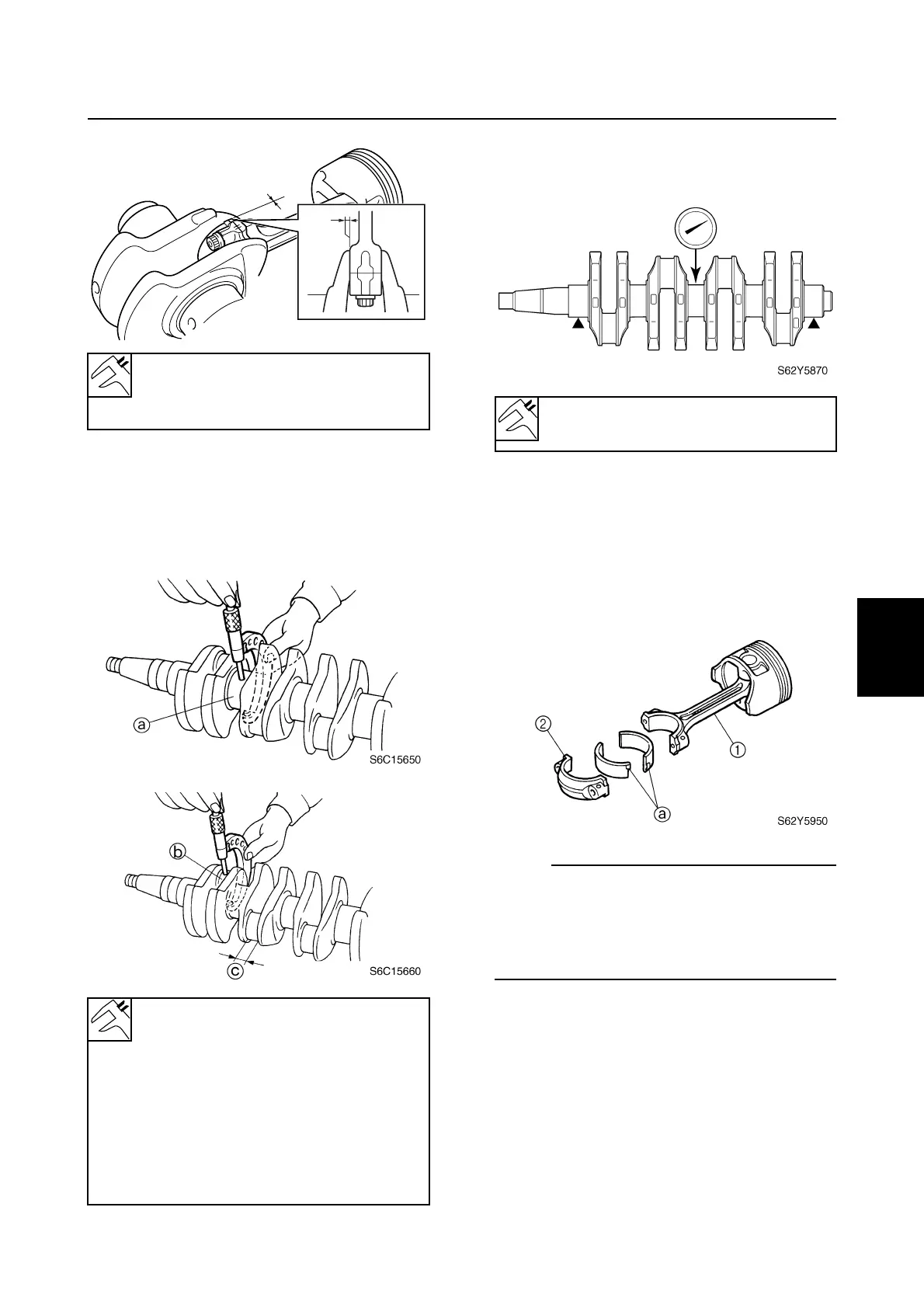

Checking the crankpin oil clearance

1. Clean the bearings and the connecting

rod.

2. Install the upper bearing into the con-

necting rod

1

and the lower bearing into

the connecting rod cap

2

.

NOTE:

• Install the connecting rod bearings in their

original positions.

• Insert the projection

a

of each bearing into

the slots in the connecting rod cap and con-

necting rod.

Connecting rod big end side

clearance

a

:

0.05–0.22 mm (0.0020–0.0087 in)

Crankshaft journal diameter

a

:

42.984–43.000 mm

(1.6923–1.6929 in)

Crankpin diameter

b

:

32.984–33.000 mm

(1.2986–1.2992 in)

Crankpin width

c

:

21.000–21.070 mm

(0.8268–0.8295 in)

S6D55800

a

a

Crankshaft runout limit:

0.03 mm (0.0012 in)

Cylinder block

Loading...

Loading...