Definitions

- x -

Sequence – refers to how the drive is started, stopped, and told which direction to run.

When the sequence comes from the digital operator (local), the drive is started and stopped

using the “RUN” and “STOP” keys on the digital operator, and direction is given via the

“FWD/REV” key. Sequence can also come from the drive’s control terminals (remote)

using either two-wire or three–wire control. The sequence inputs to the drive do NOT

require any outside voltages to activate them. Instead, contact closures (either from

switches, relay contacts or open collector circuits) activate the sequence inputs. Other

sequence sources are available.

Two-wire sequence – utilizes a “maintained” switch or relay contact. It is used on

applications where it is desirable to have the drive restart on restoration of power. It

should not be used where safety of attending personnel might be threatened by a

restart. This method is generally restricted to unattended fans & pumps, or where

another controller is entrusted with the decision to restart. Direction is controlled by

maintaining either a forward run or a reverse run command.

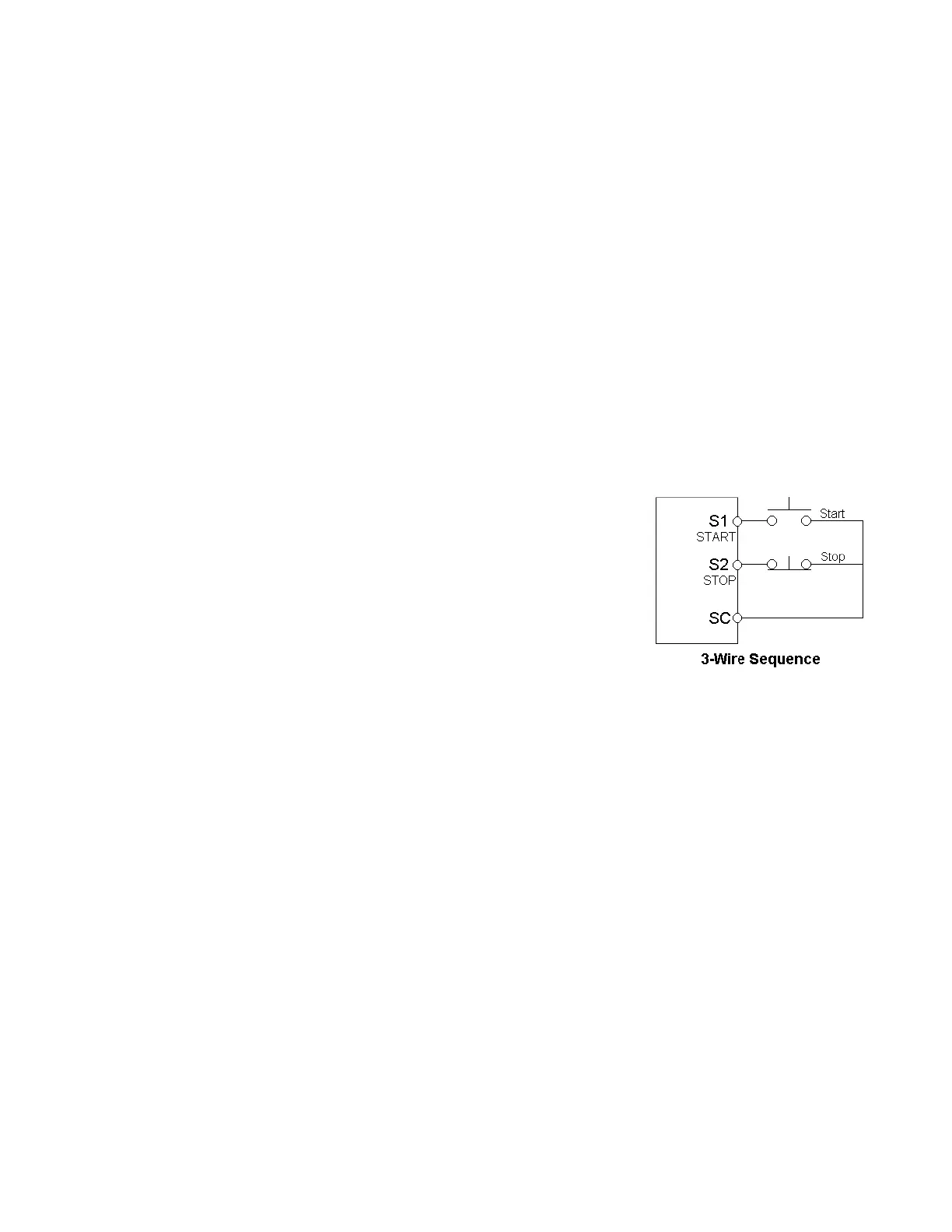

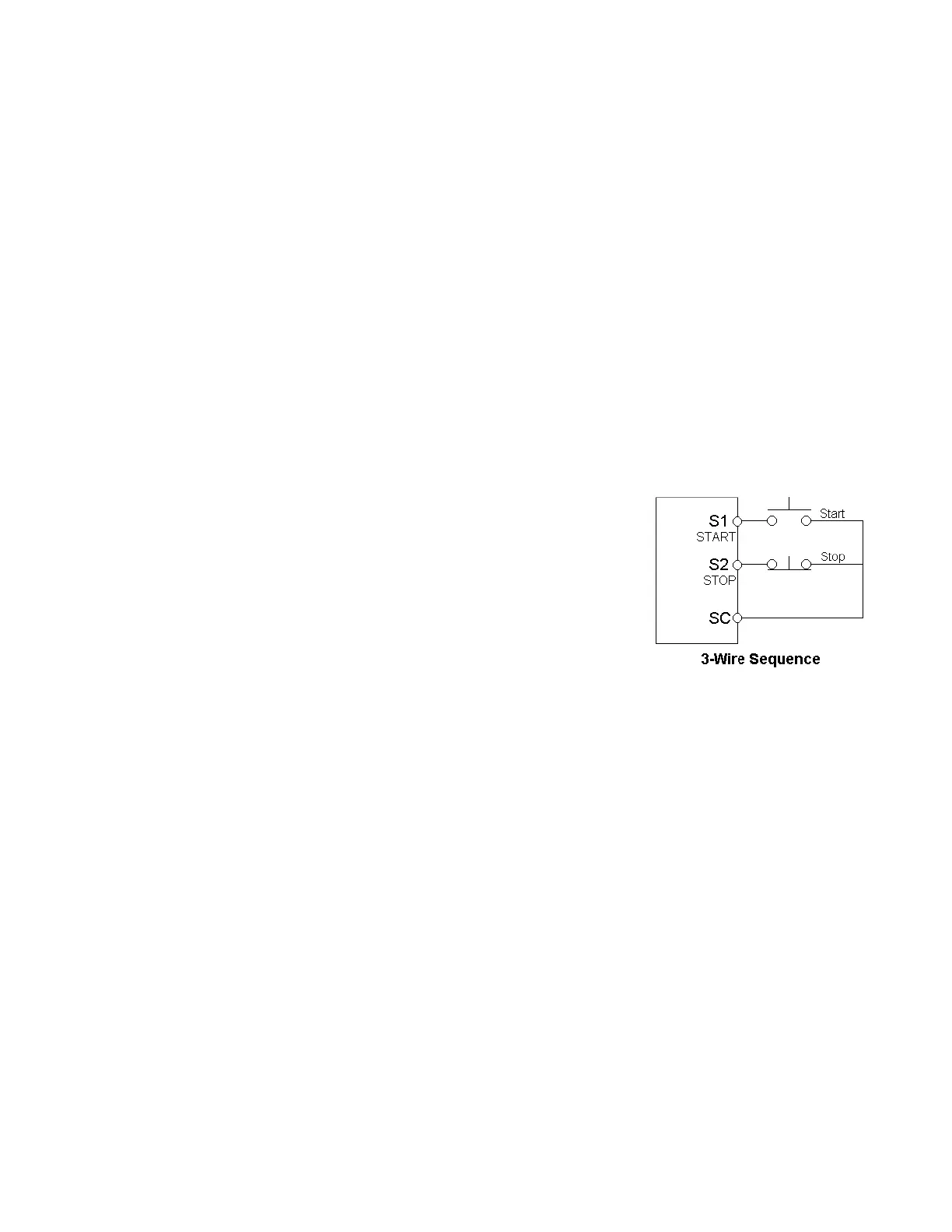

Three-wire sequence – utilizes “momentary” buttons or switches. This control

scheme emulates the traditional 3-wire motor starter control. A momentary closure of

a normally open run switch latches the drive in the RUN

mode (STOP switch must be closed or the drive will not

accept the momentary RUN command). A momentary

opening of the normally closed STOP switch unlatches

RUN mode bringing the drive to a stop. The three-wire

sequence is used where it would be dangerous for the

drive to restart after a power outage. This method

requires an intentional restart, as the RUN command is

unlatched immediately on loss of power. Direction is

determined by another maintained contact closure (closed = reverse).

Reference - The frequency reference tells the drive how fast to run the motor. There are

several source options for the frequency reference. First, the frequency reference can come

from the digital operator (local). Simply put, the motor speed can be entered into the

keypad. Second, the frequency reference can come from an analog signal (remote), such

as 0 to 10 Volts DC. When 0 Volts is applied to the drive, the drive will run at zero speed.

When 10V is applied to the drive, it will run at full speed. Apply anything in between and the

drive will run at that corresponding frequency (2.5VDC = 25% speed = 15 Hz). Other

reference sources are available.

Local Control – is when the sequence and/or reference comes from the digital operator. If

the reference is supposed to come from the digital operator, the REF LED will be off. If the

start/stop (sequence) is supposed to come from the digital operator, the SEQ LED will be

off.

Remote Control – is when the sequence and/or reference comes from the control

terminals. If the reference source is supposed to come from terminals FV or FI, the REF

LED will be on. If the start/stop (sequence) is supposed to come from the terminals (2-wire

or 3-wire control) the SEQ LED will be on.

Loading...

Loading...