- vi -

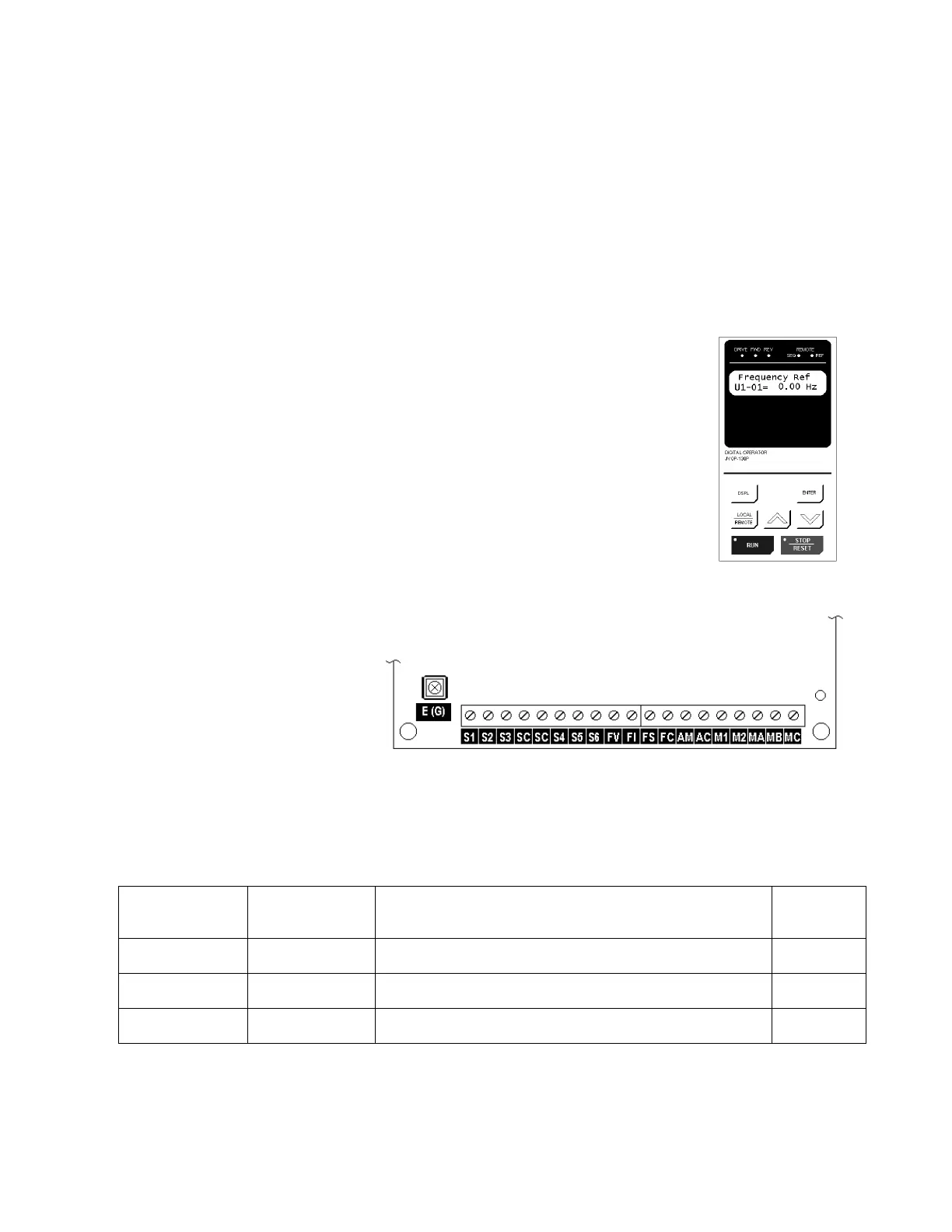

4. Replace cover and apply input power – digital operator shows “Frequency Ref

00.0 Hz”; DRIVE, SEQ, REF & STOP LEDs are on. Press the LOCAL / REMOTE

button. The SEQ & REF LEDs should go off. Press and hold the UP ARROW button

until the display shows “6.0 Hz, then press the ENTER button. Press the RUN button

and note the direction of motor rotation. If rotation is incorrect, remove power, wait for

charge light to go out, then switch wires between terminals T1 and T2. Replace the front

cover and apply input power.

5. Digital Operator

To access a “Quick Start” display, press the DSPL button until the desired display is on

the screen. Use the UP and DOWN keys to adjust the value then press the ENTER key.

To access a parameter, press the DSPL button until the word

“Parameter” is on the upper left side of the screen. Use the UP and

DOWN keys until the desired parameter number is on the right side

of the screen, then press ENTER. Use the UP and DOWN keys to

adjust the value then press ENTER then DSPL.

Before the drive will accept a RUN command, the DRIVE LED must

be on. Press the DISPL key until the DRIVE LED comes on. For

more specific information on the digital operator, Section 4.

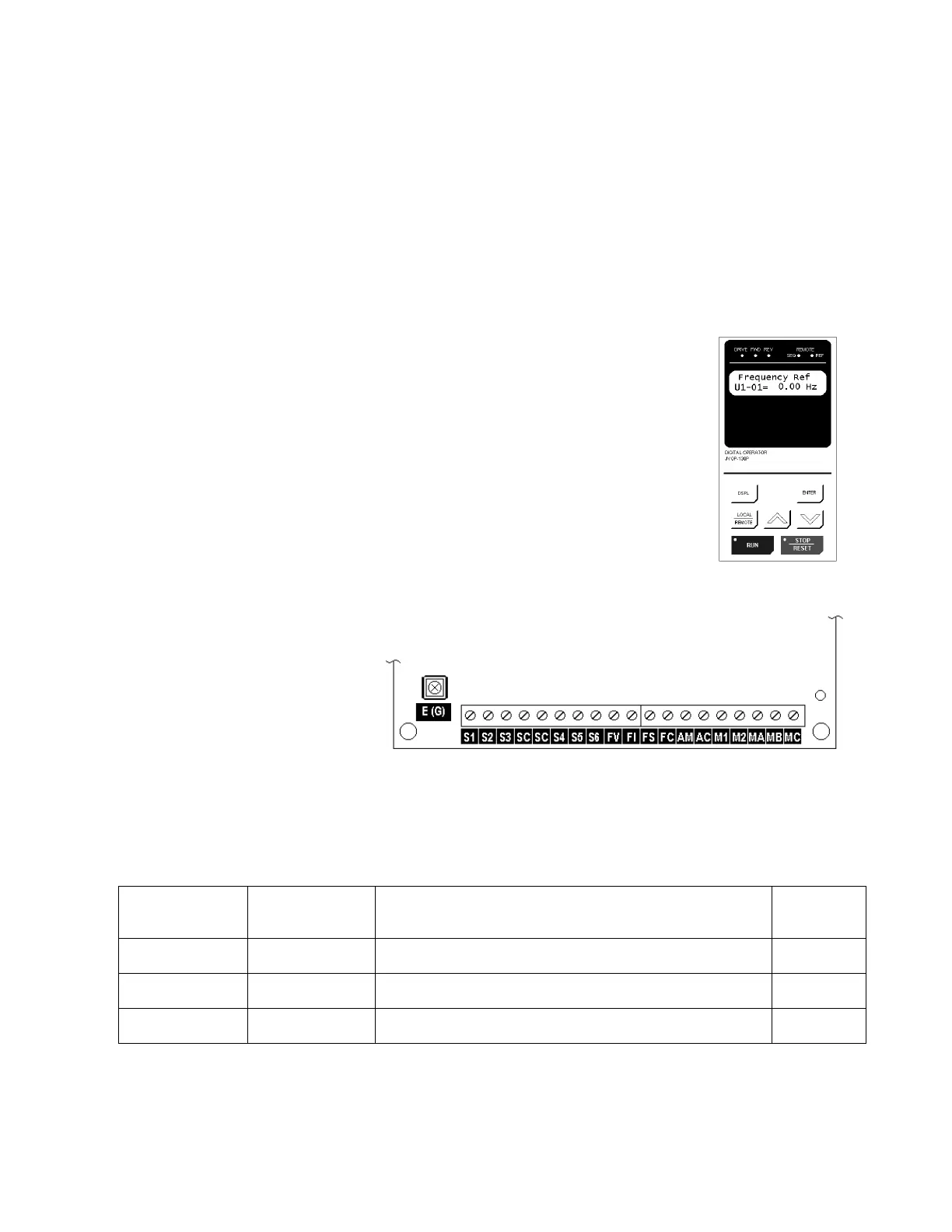

6. Control Terminal Wiring – Remove power and wait for the charge

light to go out before making control terminal connections. Control wiring should be

sized 16 to 20 AWG.

Control wiring should be

shielded, with the shield

wire connected to terminal

E(G) and the other end of

the shield left open. As

shown at right there are

two SC terminals provided

for wiring convenience.

7. Choose a configuration from Table 1 below. Each example listed below contains a

control wiring diagram, operation explanation, and all necessary programming.

Table 1: Drive Configuration Examples

Sequence*

Source

(Run / Stop)

Reference*

Source

(Motor Speed)

Description

Example

Page

Digital Operator Digital Operator This method requires no control wiring connections to the

drive. It is most often used during startup of the drive.

Example 1

2-wire

4-20 mA

This method is the same as Example 2 but the reference

comes from a remote 4 – 20 mA source such as a PLC.

Example 2

3-wire

Speed

Potentiometer

This method is similar to Example 3, but utilizes a remote

mounted speed control (potentiometer).

Example 3

* For a more detailed explanation of sequence and reference, see Definitions page.

GPD506/P5 Control Terminals

Loading...

Loading...