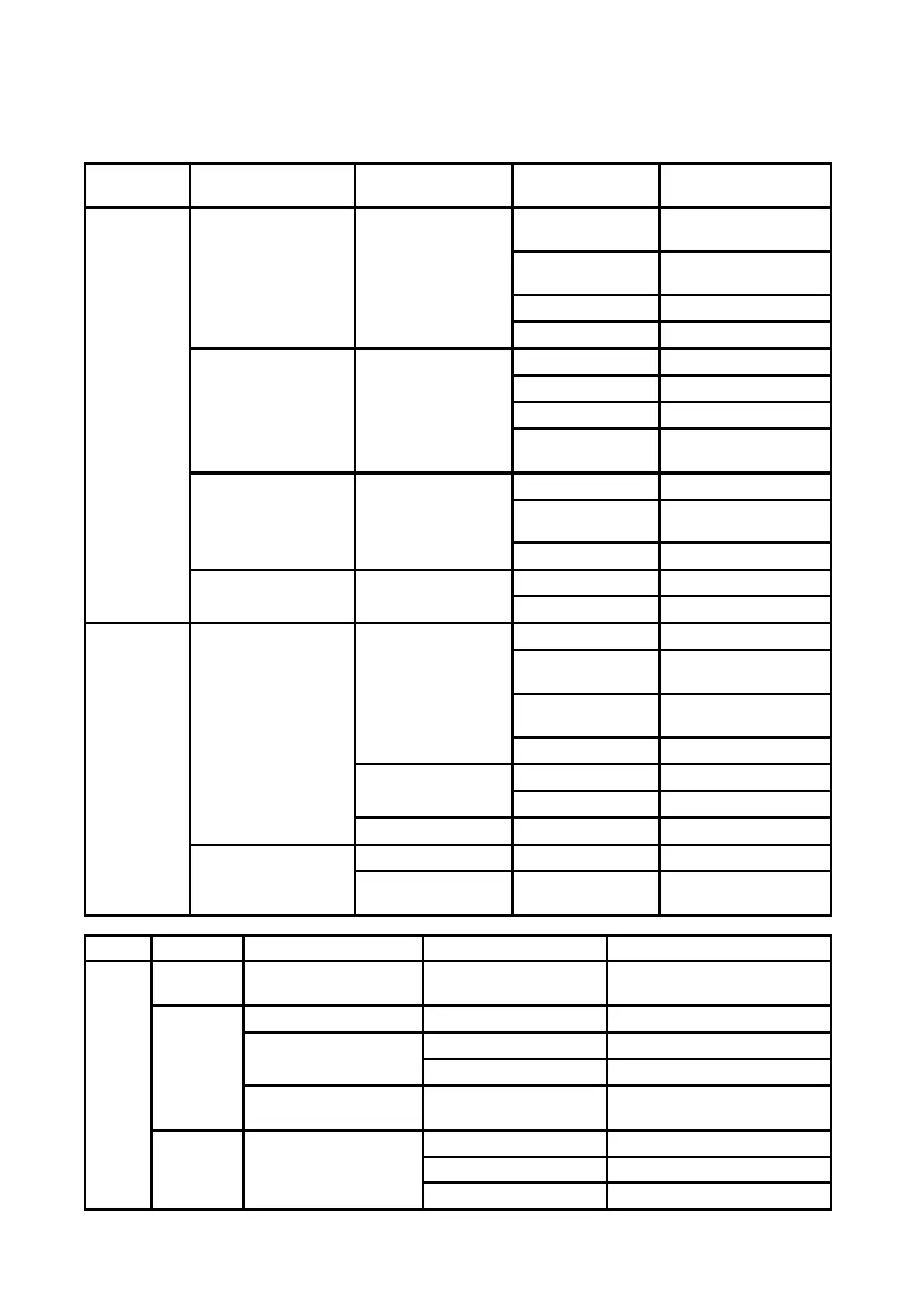

Diagnosing Malfunctions

1. Tracing Faults

PROBLEM CONDITION CAUSE CORRECTIVE

MEASSURE

1.

Compressor

Abnormal sound Inlet sound

Outlet sound

Insufficient

lubrication

Replenish

Insufficient belt

tension

Adjust

Released holder Tighten connections

Clutch failure Check

Abnormal revolutions Drive interruption Damaged parts Check, replace

Clutch slipping Check, replace

Lack of lubricant Replenish

Belt tension

released

Adjust

Refrigerant or oil

leakage

Refrigerant or oil

leakage

Damaged sealing Replace

Head screw is

loosened

Tighten the screws

D-ring damaged Replace

Abnormal pressure Too low / high

pressure

Insufficient cooling Adjust

Compressor Replace

2. Engine Low pressure or not

working

Normal engine

operation

Air inlet is blocked Remove

Evaporator freezing Minimum pressure

control

Fan switch

damaged

Replace the switch

Compressor Replace

Abnormal motor

operation

Engine failure Replace

Broken wire Replace

Air leak Tube leak Check, tighten

Fan cannot be

operated

Engine Switch failure Check, tighten

Abnormal motor

operation

Engine failure Replace

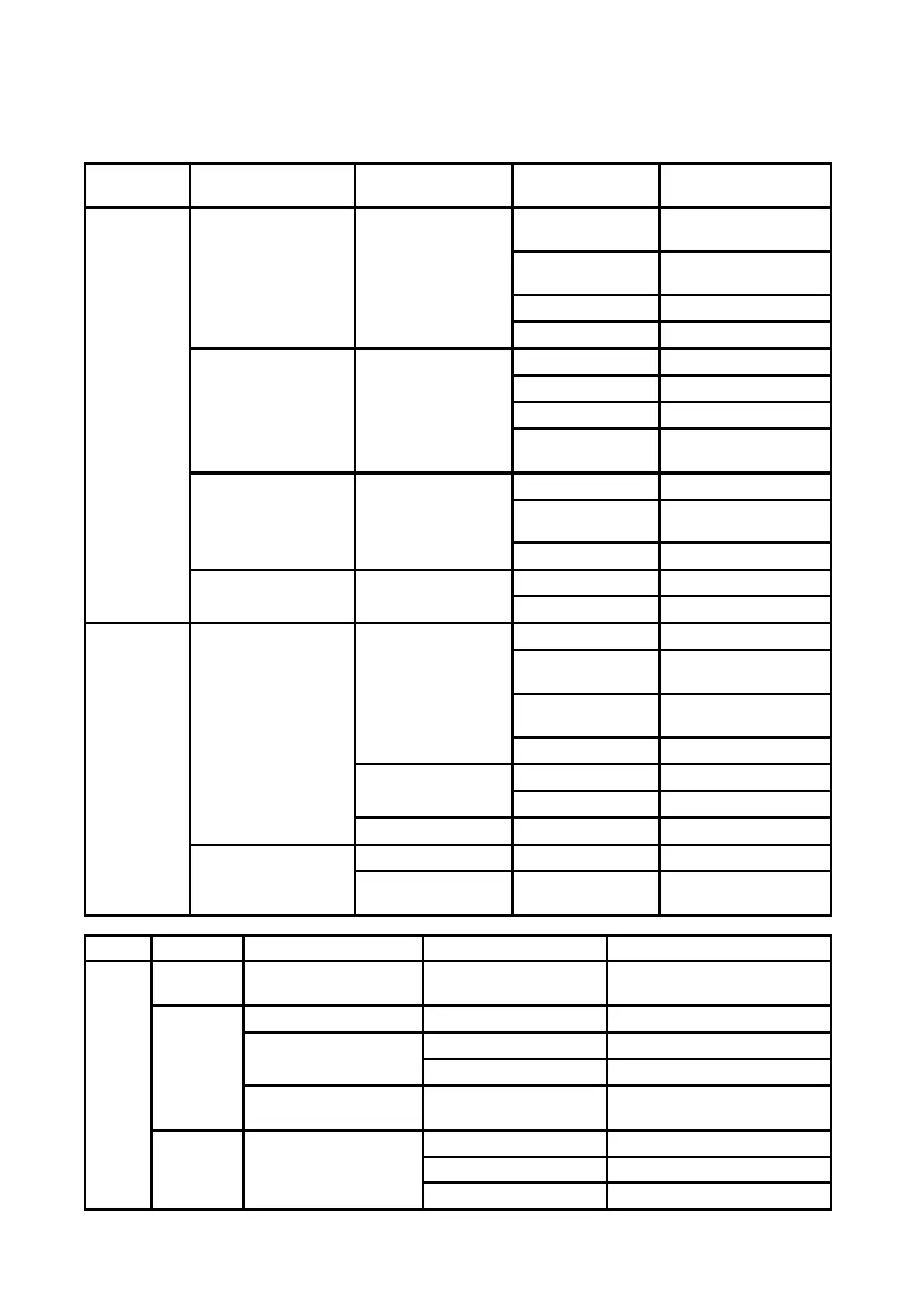

PROBLEM CONDITION CAUSE CORRECTIVE MEASSURE

3.

Clutch

Noise Regular / irregular

noise

Interference with

ulle

Check the position of the

compressor

Disengaged Engaged sometimes Wire defect Check the wire

Engaged by pushing by

hand

Large clutch gap Adjust

Low voltage Check the battery

Without a faulty

conductor

Defect Replace

Slipping Slipping during rotation Low voltage Check the battery

Greasy bar on clutch Clean

Defect Replace

Loading...

Loading...