PTO Gear Selection Leve

Important: Always use the clutch when engaging or disengaging the PTO or changing PTO

speed. Let the PTO driven implement come to a complete stop before changing.

Operation of the Hydraulic Circuit

Caution: When working with the 3-point linkage, keep well clear of the operating radius of the

lift arms and any attached implement. This is to avoid the risk of injury in the case of incorrect

manoeuvres.

Position Control

Implements can be raised and lowered with the hydraulic position control lever and can be stopped at any

position by stopping the lever.

To ensure a consistent working depth the adjustable stop can be set to ensure that the implement returns to

the same depth every time.

To raise the implement: Pull the lever back.

To lower the implement: Push the lever forward.

WARNING: After finishing work, always lower the implement to the ground and switch off the

en

ine. A

l

the

arkin

brake to

revent in

uries and accidents

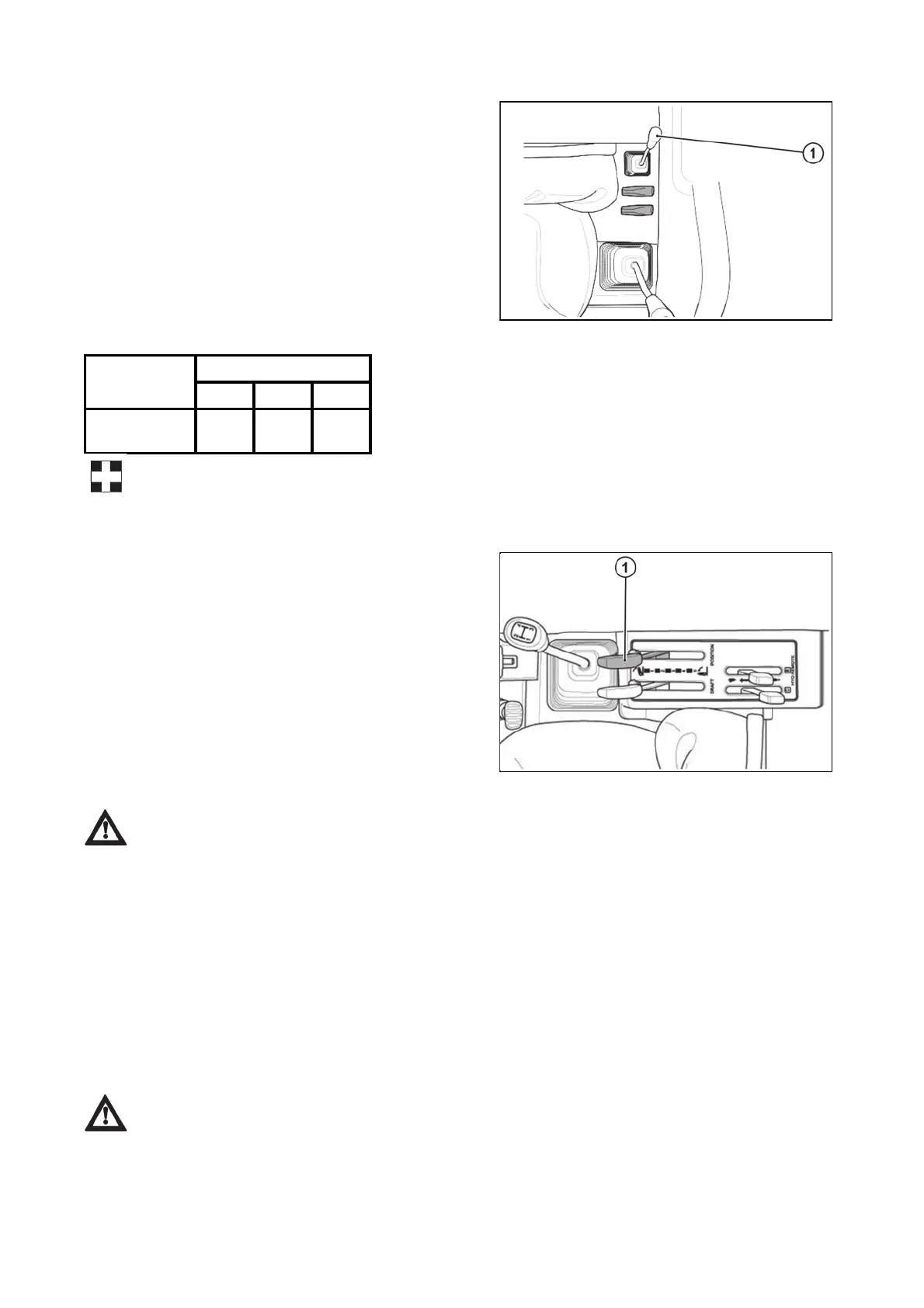

Your tractor is equipped with 2 Speed PTO to suit range o

applications and conditions.

1 - PTO Shift Lever

HODP071

MODEL POSITION

1st 2nd 3nd

HORTUS

CL65 / HS65

540 750 1,000

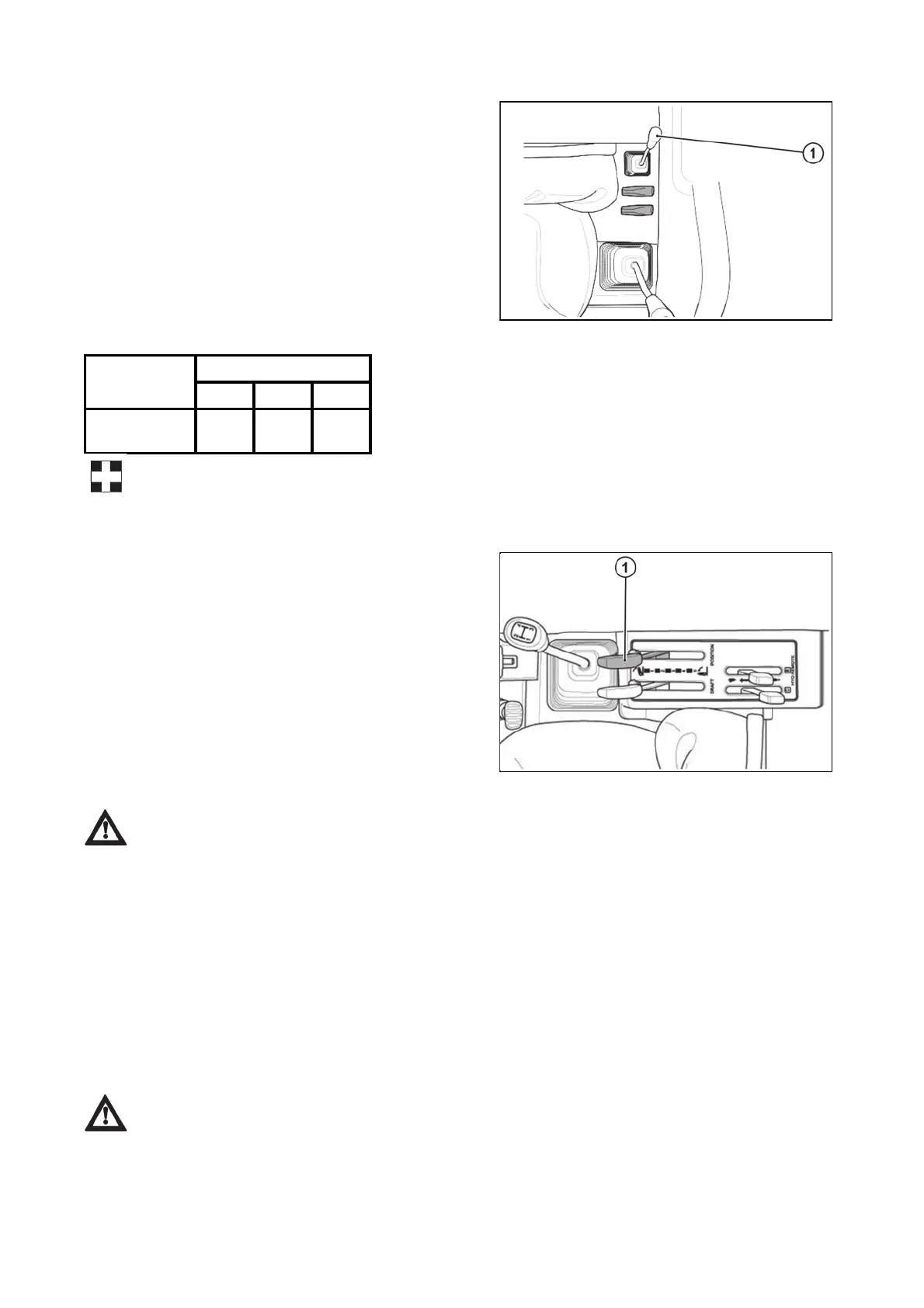

The external and internal hydraulic circuits are driven by

a engine-driven hydraulic pump and controlled by a lever

located next to the driver.

1. Position control lever

HODP072

DESCRIPTION OF TRACTOR CONTROLS

Loading...

Loading...