MAINTENANCE AND FUNCTION / TOOLHEADS

58

MAKING PLASTIC STICK TO PRINTBED

To keep the print hold rmly to the table while printing, we can use measure described below:

Heating the bed table - especially important for ABS plastic. Usual temperature

is 100-120°C. With higher temperatures plastic sticks better, and deforms less during

printing (especially for large objects).

A

Applying layer of Kapton tape on the bed (must be used without any other

substances - just the tape). Works with ABS.

C

Applying layer of paper masking tape, and wiping it with alcohol.

Works very well for PLA.

D

Applying layer of paper glue (Pritt Stick for example). When dried, holds the print

nicely, and allows easy removal aerwards. Should be used with heated bed (60°C)

and cooled down for removing.

E

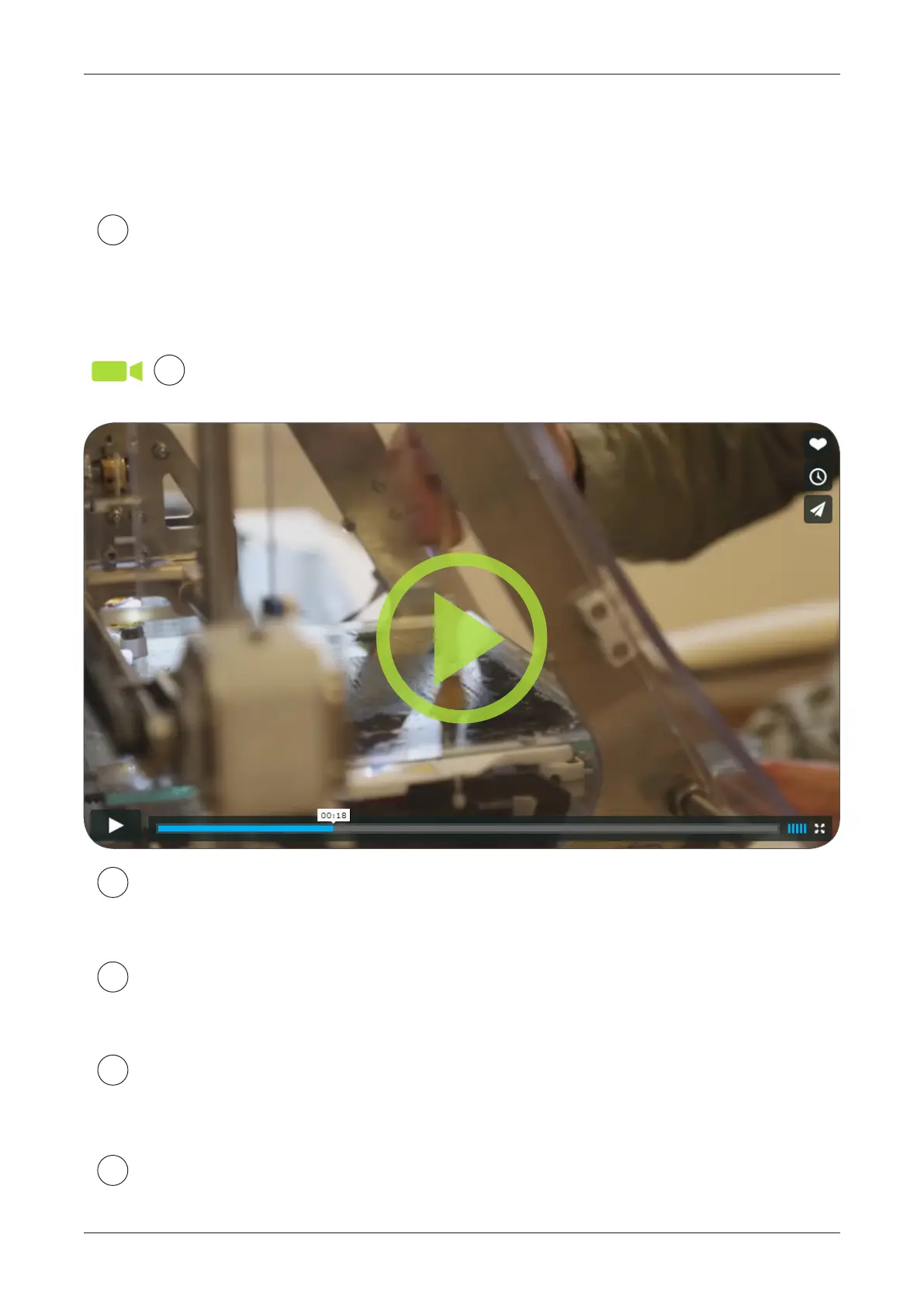

Applying layer of dissolved ABS plastic (ABS juice). Watch the video:

https://vimeo.com/80748630

B

Using Build Tak (adhesive print surface), works very well with PLA and ABS. It is

recommended to generate prints with Power Ra feature (easier to remove).

F

Loading...

Loading...