Program features 69

or fan applications. For these applications, the torque required follows the square

relationship with frequency. Therefore, if the voltage is varied using the square

relationship, the motor operates at improved efficiency and lower noise levels in

these applications.

The U/f function cannot be used with energy optimization. If parameter 45.11 Energy

optimizer is set to Enable, parameter 97.20 U/F ratio is ignored.

Settings

Parameter 97.20 U/F ratio (page 363).

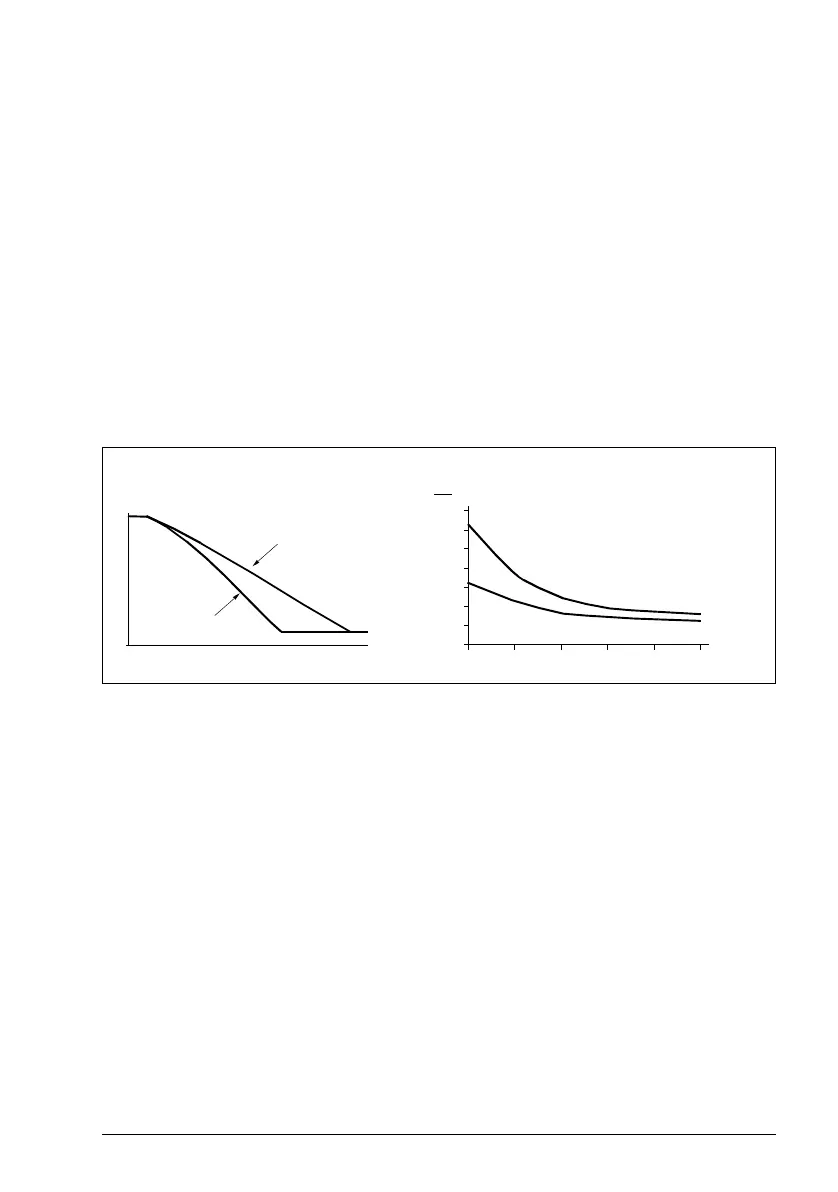

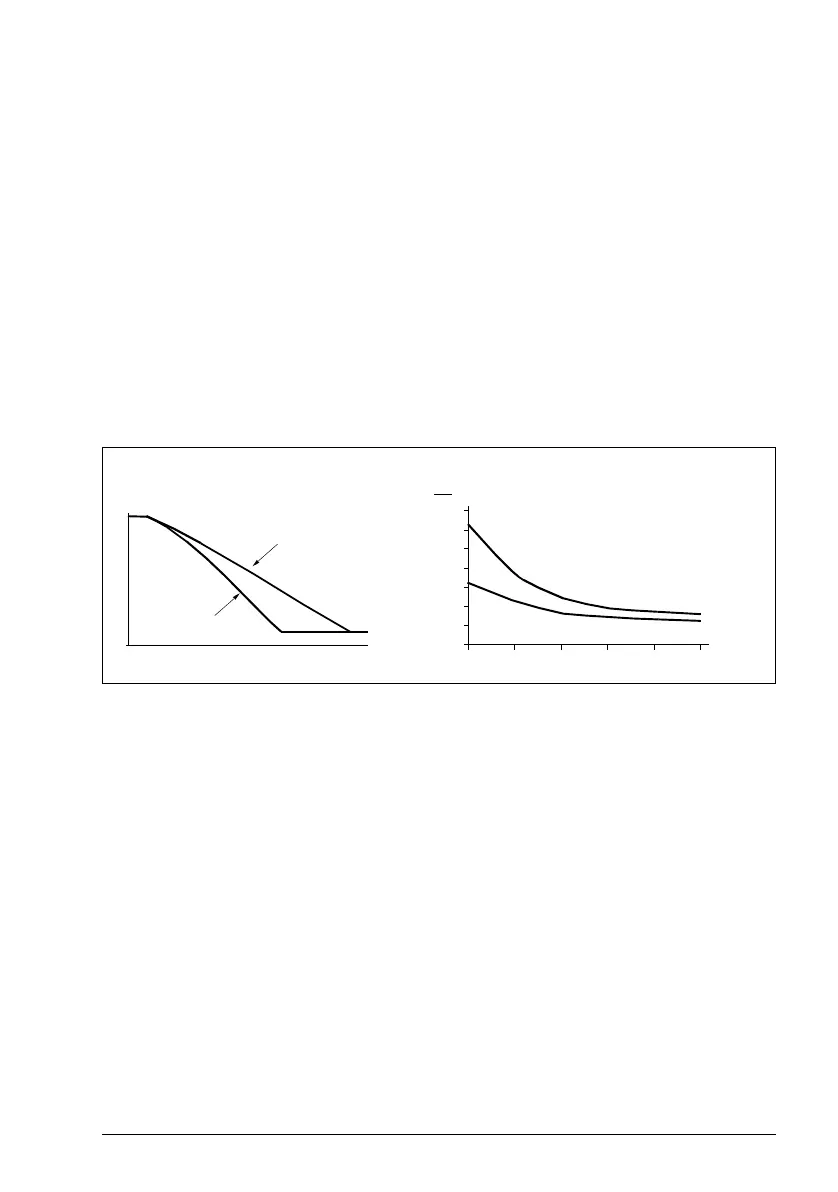

Flux braking

The drive can provide greater deceleration by raising the level of magnetization in the

motor. By increasing the motor flux, the energy generated by the motor during

braking can be converted to motor thermal energy.

The drive monitors the motor status continuously, also during flux braking. Therefore,

flux braking can be used both for stopping the motor and for changing the speed. The

other benefits of flux braking are:

• The braking starts immediately after a stop command is given. The function does

not need to wait for the flux reduction before it can start the braking.

• The cooling of the induction motor is efficient. The stator current of the motor

increases during flux braking, not the rotor current. The stator cools much more

efficiently than the rotor.

• Flux braking can be used with induction motors.

Two braking power levels are available:

• Moderate braking provides faster deceleration compared to a situation where flux

braking is disabled. The flux level of the motor is limited to prevent excessive

heating of the motor.

• Full braking exploits almost all available current to convert the mechanical braking

energy to motor thermal energy. Braking time is shorter compared to moderate

braking. In cyclic use, motor heating may be significant.

T

Br

20

40

60

(%)

Motor

speed

No flux braking

Flux braking

T

Br

= Braking torque

= 100 Nm

Flux braking

No flux braking

t (s)

f (Hz)

Loading...

Loading...