Process connections (option)

The system can handle the following input and output signals from the peripheral

equipment:

• Digital I/O

- up to 96 inputs and 96 outputs

Requires 1-6 digital I/O boards (option)

• Analogue I/O

- up to 4 inputs and 4 outputs

Requires 1 analogue I/O board (option)

• Combi I/O

- 16 digital in- and 16 outputs + 2 analogue outputs

Requires 1 AD combi I/O board (option)

• Computer communication via RS 232 interface.

Requires "Computer link" (option).

• I/O remote bus for Allen Bradly 1771 RIO link, up to 128 in / 128 out (option)

• Control signals for 1-6 external axes.

Requires one extra board (option).

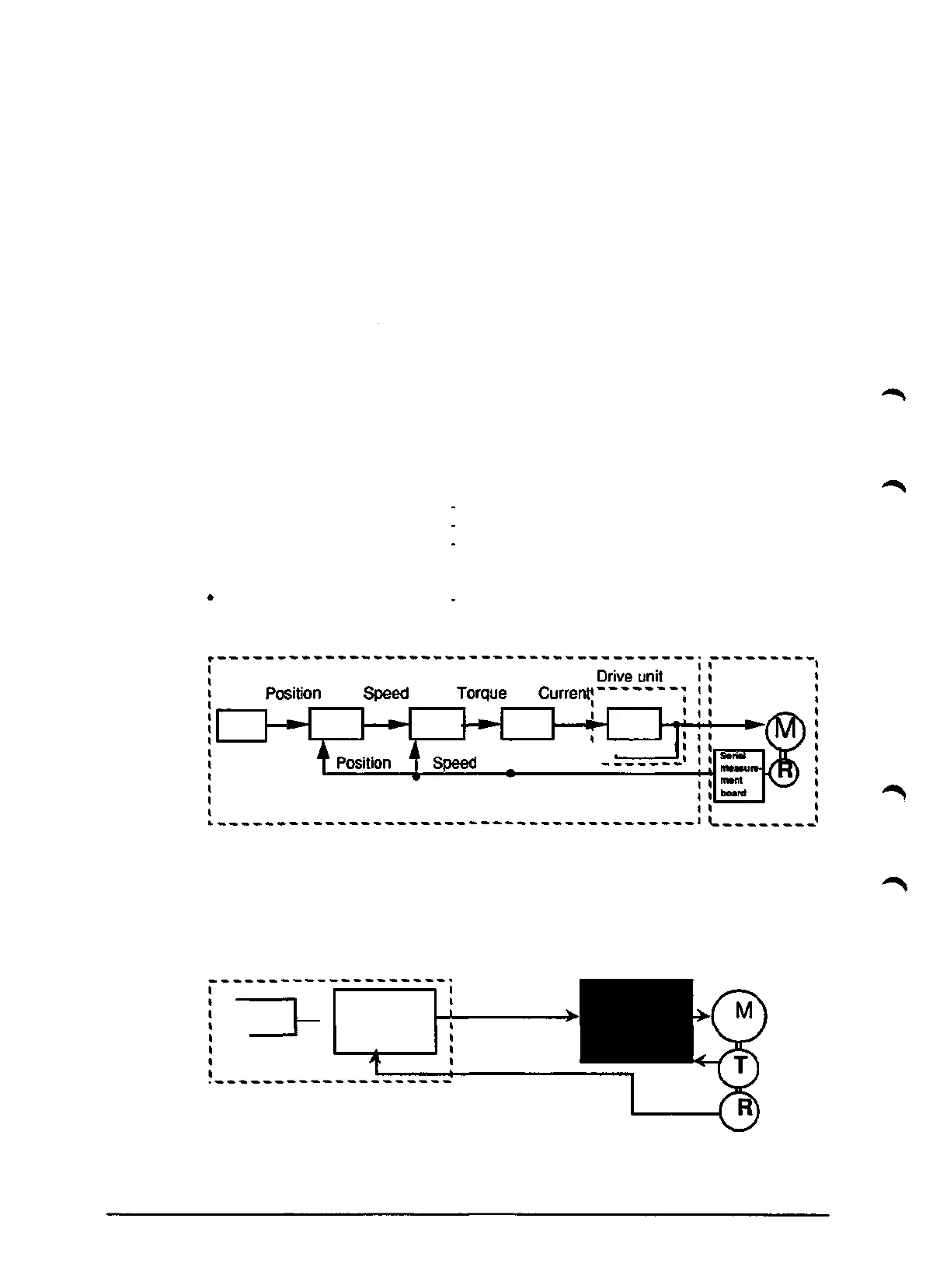

Drive system

The drive system, for the robot motors and one integrated axis 7 (option), consists

of the following units.

• Computer board

• Rectifier unit

• Drive unit

Serial measument board

Control system

for overall control.

for power supply to the drive units.

receives current references from the computer

board. The current references control the

power amplifier supplying current to the motor.

reads the resolver

Manipulator

A » A Curren

TRotor angle-

Fig. 3.5 AC drive system, robot axes and integrated axis 7.

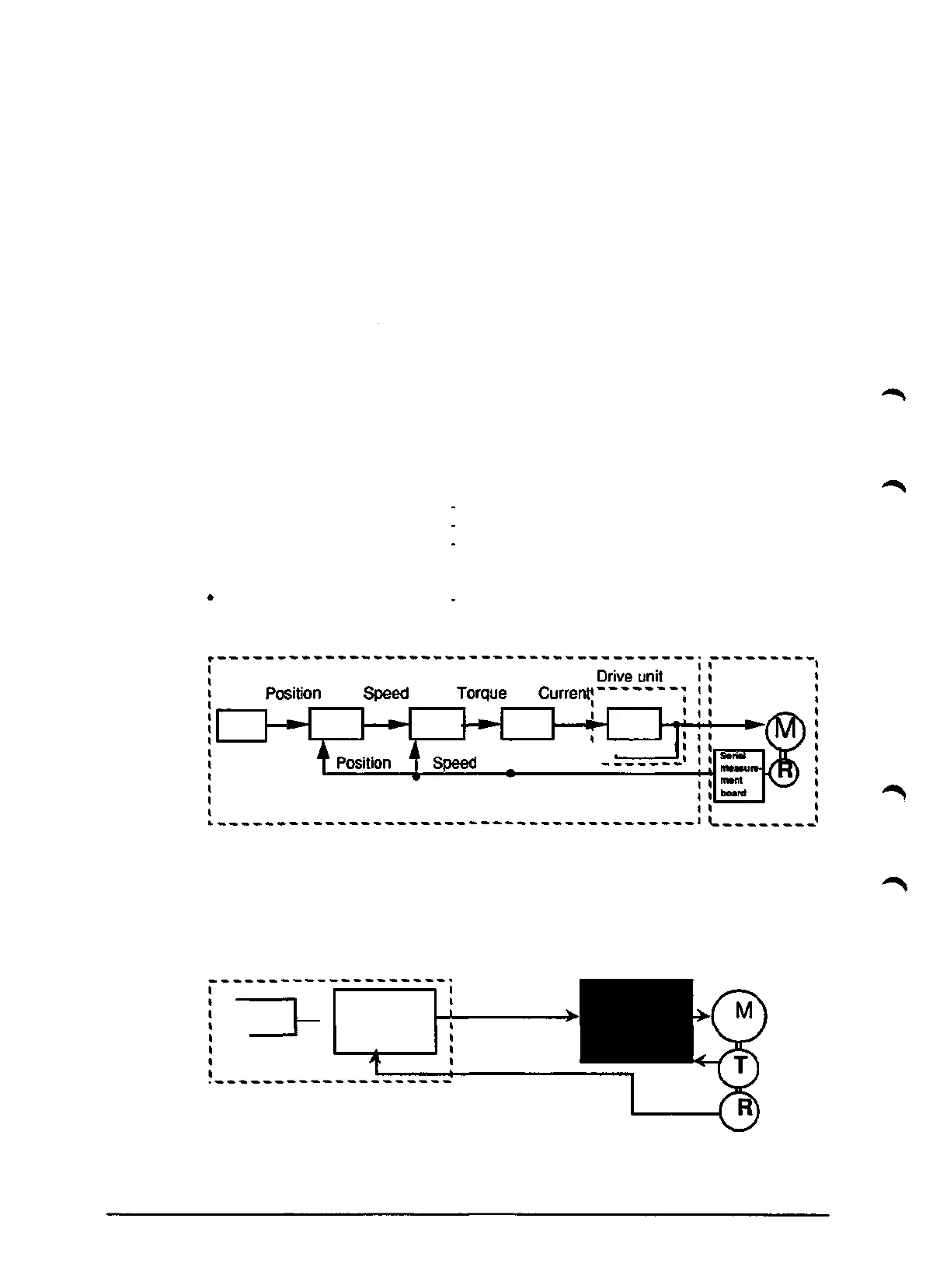

Drive unit for optional external axes is located outside the control system.

Thesedrive units are provided with speed referense by the control system.

Control cabinet

Separate drive unit

outside control system

t

'osition >.

Control board,

external axes

Speed

Position

Fig. 3.6 Drive system external axis.

Description

1KB 2000

12

Loading...

Loading...