36 ZX2 GAS-INSULATED MEDIUM VOLTAGE SWITCHGEAR

• Release the gas (N

2

) from the relevant busbar

compartment into the atmosphere by pressing

the valve pin (see HB 645 en) until the pressure

is equalised.

• Dismantle the transport lid on the heat sink and

the pressure relief lid on the busbar compart-

ment.

• Remove the transport drying agent bags from

the gas compartments and replace them with

new bags with the same quantity of drying

agent. Continue assembly immediately, so as

not to impair the effectiveness of the drying

agent material.

• Clean the sealing surfaces of the busbar com-

partment, the heat sink and the sealing ring

with a dry, clean, non-fraying cloth.

Important note

Thinly grease the entire surface of the

sealing ring with silicone paste.

• Set the sealing ring on the roof plate of the bus-

bar compartment and align it symmetrically to

the opening. Use suitable lifting gear to set the

heat sink on the busbar compartment in such a

way that the relevant stud bolts in the busbar

enclosure engage in the bores in the flange

plate on the heat sink, taking care to ensure that

the sealing ring is correctly positioned in the

slot of the heat sink flange.

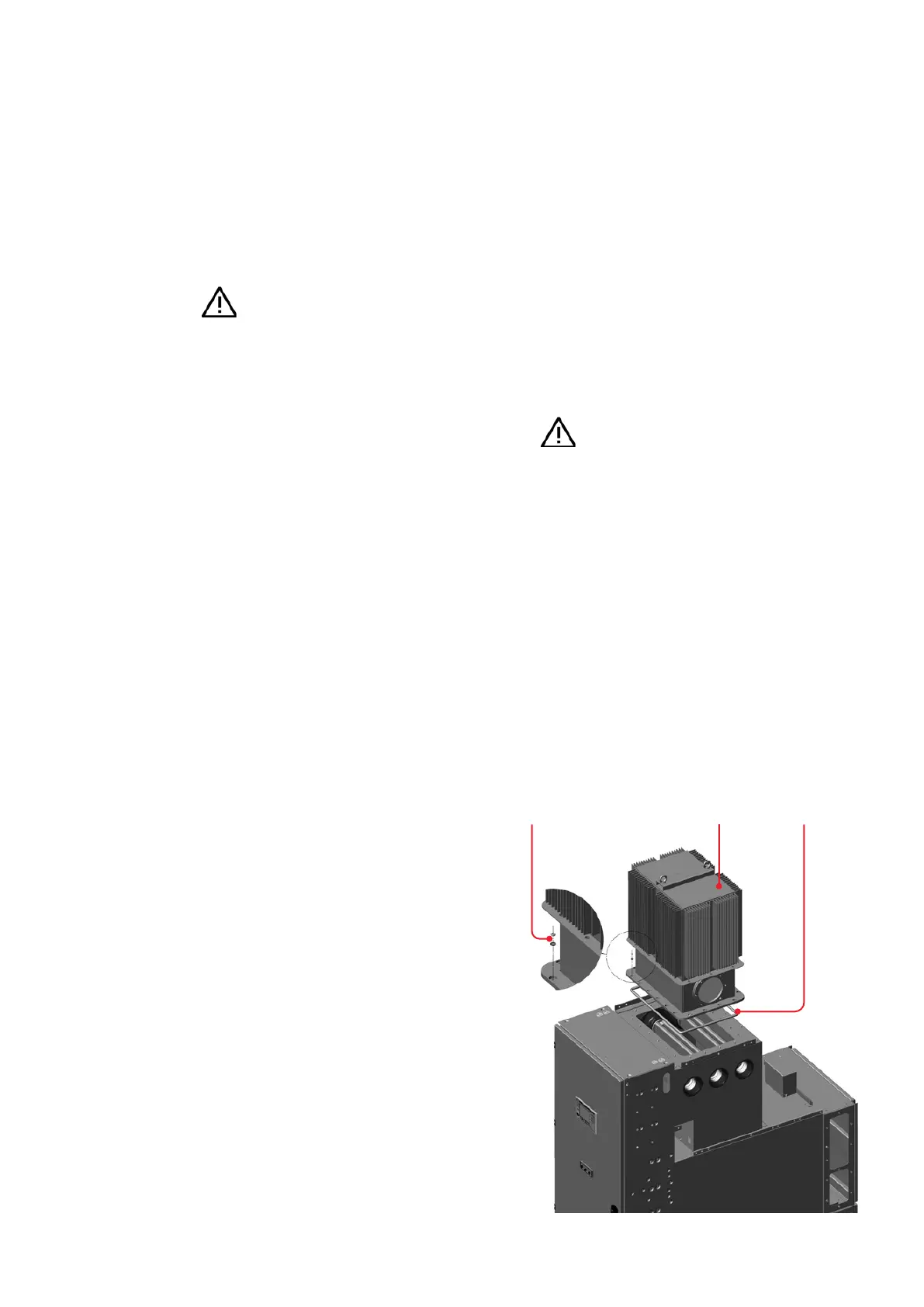

3.3.4. Installation of the heat sinks

Heat sinks fitted on the busbar compartment for

rated currents > 2500 A are as a rule supplied sep-

arately and installed after the panels have been

set up.

The relevant busbar compartments are filled with

N

2

(nitrogen) for transport. (With regard to the

gas work required, consult instruction manual

HB 645 en – use of SF

6

insulating gas).

Important note

The weight of a heat sink is approx.

200 lbs. Use suitable lifting gear (e.g. a

heat sinks. We recommend having

installation performed by two fitters.

Observe the relevant accident prevention

regulations in the country of installation.

• Follow the installation drawings supplied when

fitting the heat sinks.

Assembly must take place in as clean (dust-free)

conditions as possible.

—

Fig.3.3.4.1:

Installation of

the heat sinks

Sealing

ring

Heat

sink

Loading...

Loading...