18 ZX2 GAS-INSULATED MEDIUM VOLTAGE SWITCHGEAR

Cleaning the busbar sockets, the contact tubes,

the cable sockets, the sockets for voltage trans-

formers, the test sockets and the outer cones

• Degrease and clean the components with

intensive cleaner M.T.X. 60 forte.

Important note

Assemble the components immediately

to avoid soiling.

3.1.4. Handling sulphur hexafluoride (SF

6

This product contains Sulphur hexafluoride

(SF

6

) (

1

).

As a rule, no gas work is required during

installation.

Hazard warning

We recommend that gas work should only

be performed by personnel trained in the

handling of SF

6

. Gas may only be

extracted by certified personnel. See

manual HB 645 en “Use of SF

6

insulating

gas” for details on handling SF

6

.

switchgear room

When a raised false floor is used, load-bearing

sections of the floor frame serve as supports for

the panels. No additional foundation frame is

necessary.

Hazard warning

The slabs of the raised false floor must

be fastened to the supporting frame.

If there is a concrete floor a foundation frame is

required.

Important note

Maintain the following evenness and

straightness tolerances when installing

the foundation frame or a raised false

floor:

•

100 inch

•

100 inch,

but max. 0.04 inch for the entire length

Consult the order documents for the position of

the foundation bars in the switchgear room.

If no standard ABB foundation frames are used,

observe the relevant construction and laying

drawings for the special frames.

3.2.1. Installation of standard foundation

frames

Two versions of standard foundation frames are

available.

Type 1: Foundation frames made of aluminum

profiles which have to be fixed to the concrete

floor. These frames have to be embedded in

screed.

Type 2: Reinforced, earthquake-proof foundation

frames made of steel profiles which have to be

fixed to the concrete floor. These frames do not

have to be embedded in screed.

Both versions are pre-assembled delivered to site.

3.2.1.1. Foundation frames made of aluminum

profiles, type 1

Installation principle:

The foundation frames are bolted together at the

front and rear and three times along the

longitudinal sections. Vertical alignment is

effected by jacking screws. Brackets are used to

fasten the frames to the floor. The foundation

frames are finally embedded in floor topping to

provide their load bearing capacity.

Detailed description of installation

• Position the first foundation frame in the

correct location on the concrete floor.

• Align the foundation frame vertically with the

four screws

1

, taking account of any deviation

in floor level in the direction of the foundation

frames which are still to be laid.

• Fasten the brackets

2

of the foundation frame

to the floor, using one knock-in anchor

5

and

—

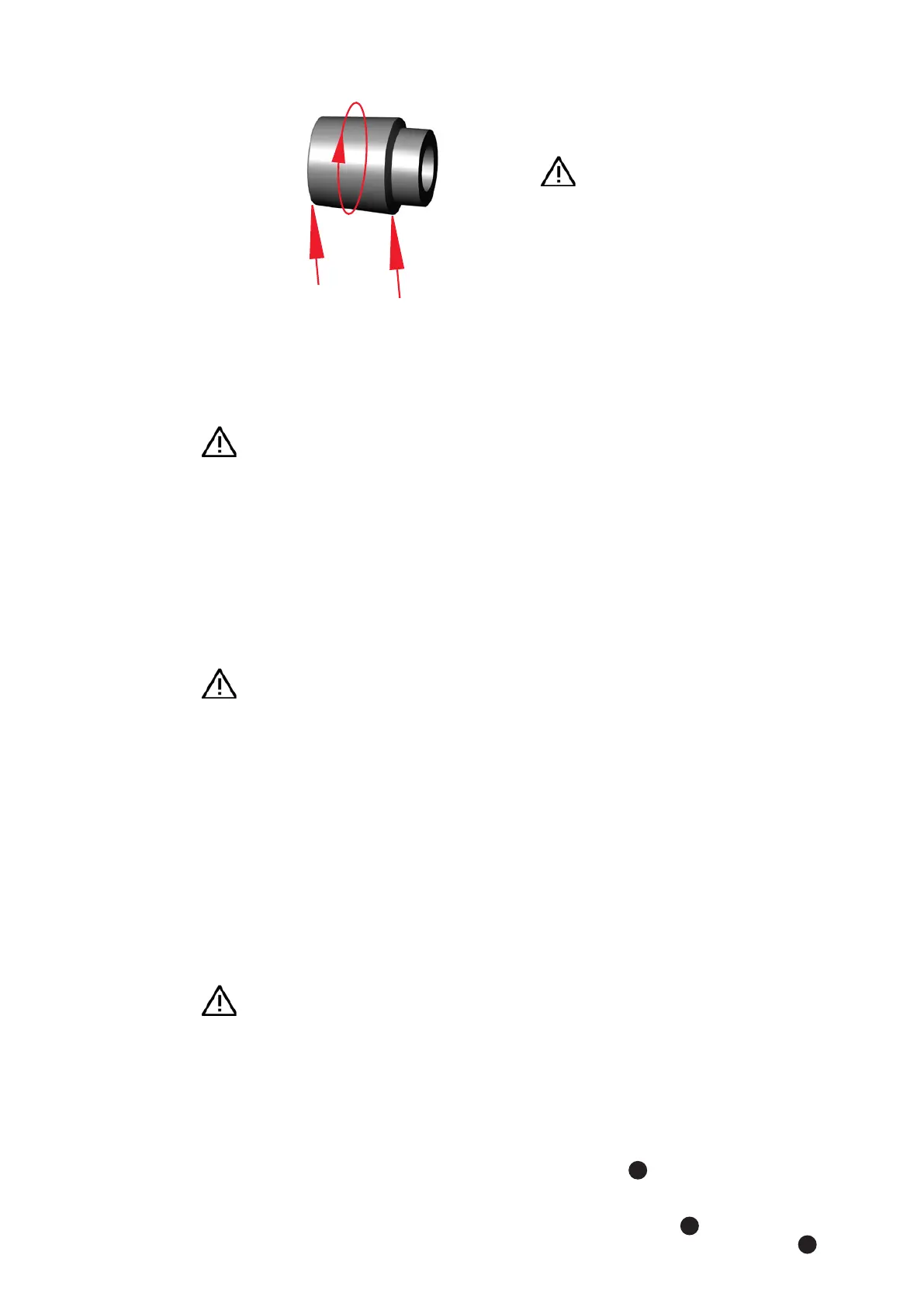

Fig.3.1.3.4:

Greasing the silicone

insulating part of

the blanking plug for

voltage transformer

sockets in the area

between the arrows

—

Fig. 3.1.3.4

1. SF

6

is a fluorinated greenhouse gas with a GWP of 22800.

The maximum quantity per panel is 40 lbs, divided into maximally

four gas compartments.

That corresponds to a CO

2

equivalent of 404 tn. l.

Each gas compartment has a gas leakage monitor, and

therefore regular leakage testing (to Fluorinated

Gas Regulation 517/2014) is not required.

Loading...

Loading...