ADTECH9 Series CNC Maintenance Manual

- 36 -

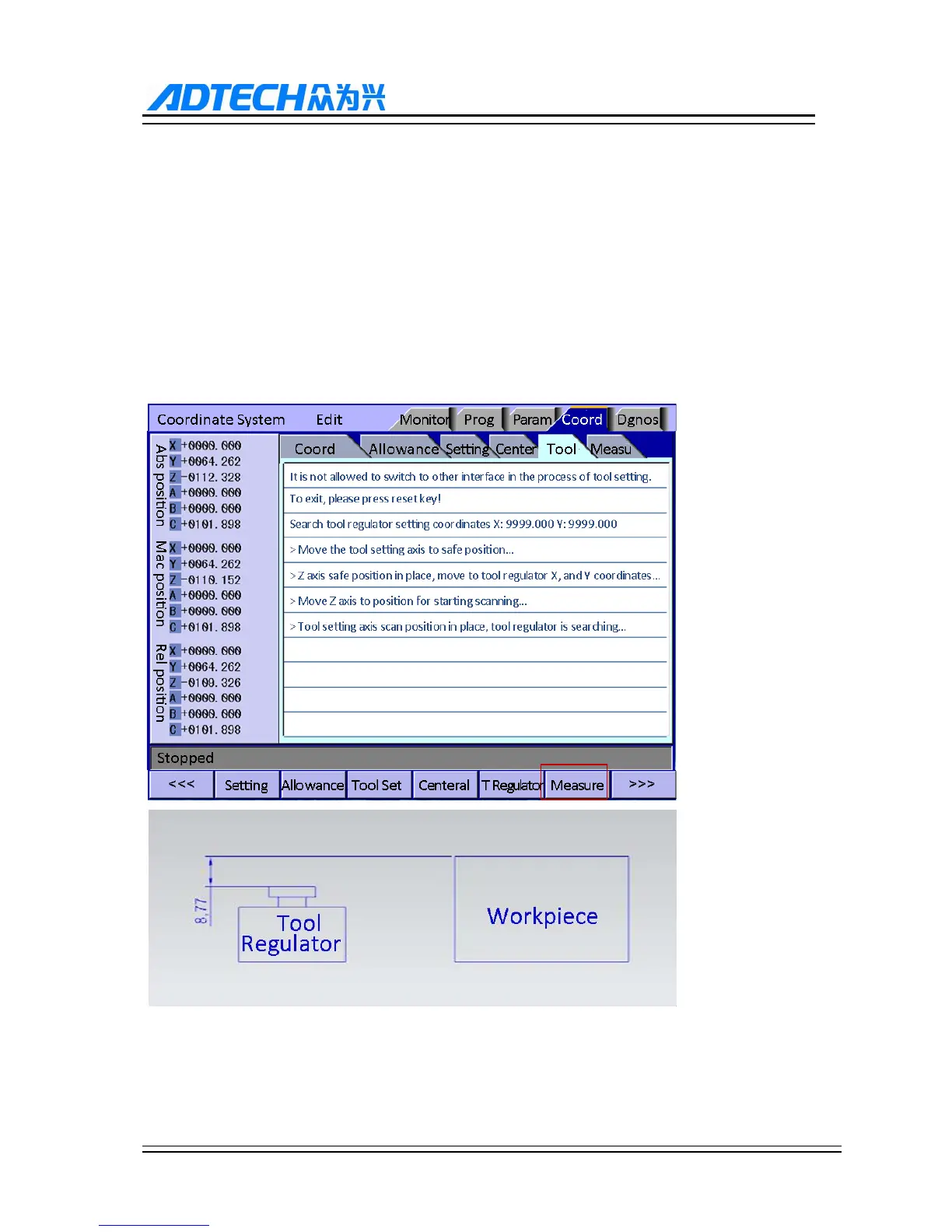

workpiece coordinate zero point is -100+10 = -90, which is the workpiece zero point. The system sets the

workpiece zero position by adding mechanical coordinate of tool regulator scanning point with the offset. For

the tool regulator installed in a fixed manner, this parameter is generally tested using the measurement function.

To do this, you shall first select a tool, after setting the workpiece coordinate system, you shall activate the

measurement function, and the system will scan the tool regulator signal, and after scanning is completed, it will

subtract the machine coordinate of the workpiece zero from the machine coordinate of the tool setting point. In

the set offset, this parameter can also be input manually. For the setting of tool block, input thickness of the tool

block to the parameter. Generally, the offset is positive when the workpiece origin is above the tool setting point,

and negative when workpiece point is above the tool setting point (such as the tool block).

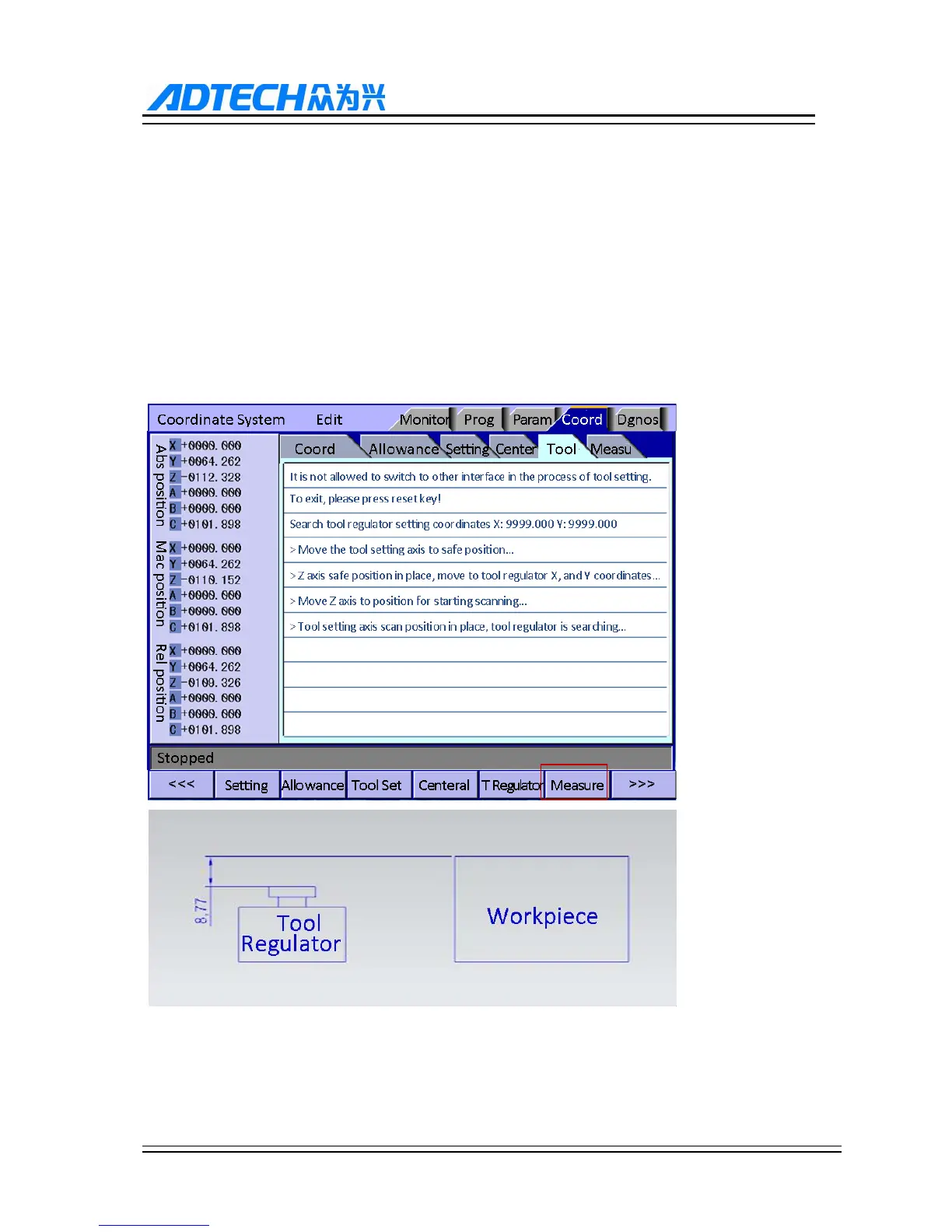

In the above figure, the distance from the top surface of the workpiece (i.e., the origin of the coordinate system

Z-axis) to the top surface of the tool regulator is the offset value of the Z coordinate system.

Loading...

Loading...