ADTECH9 Series CNC Programming Manual

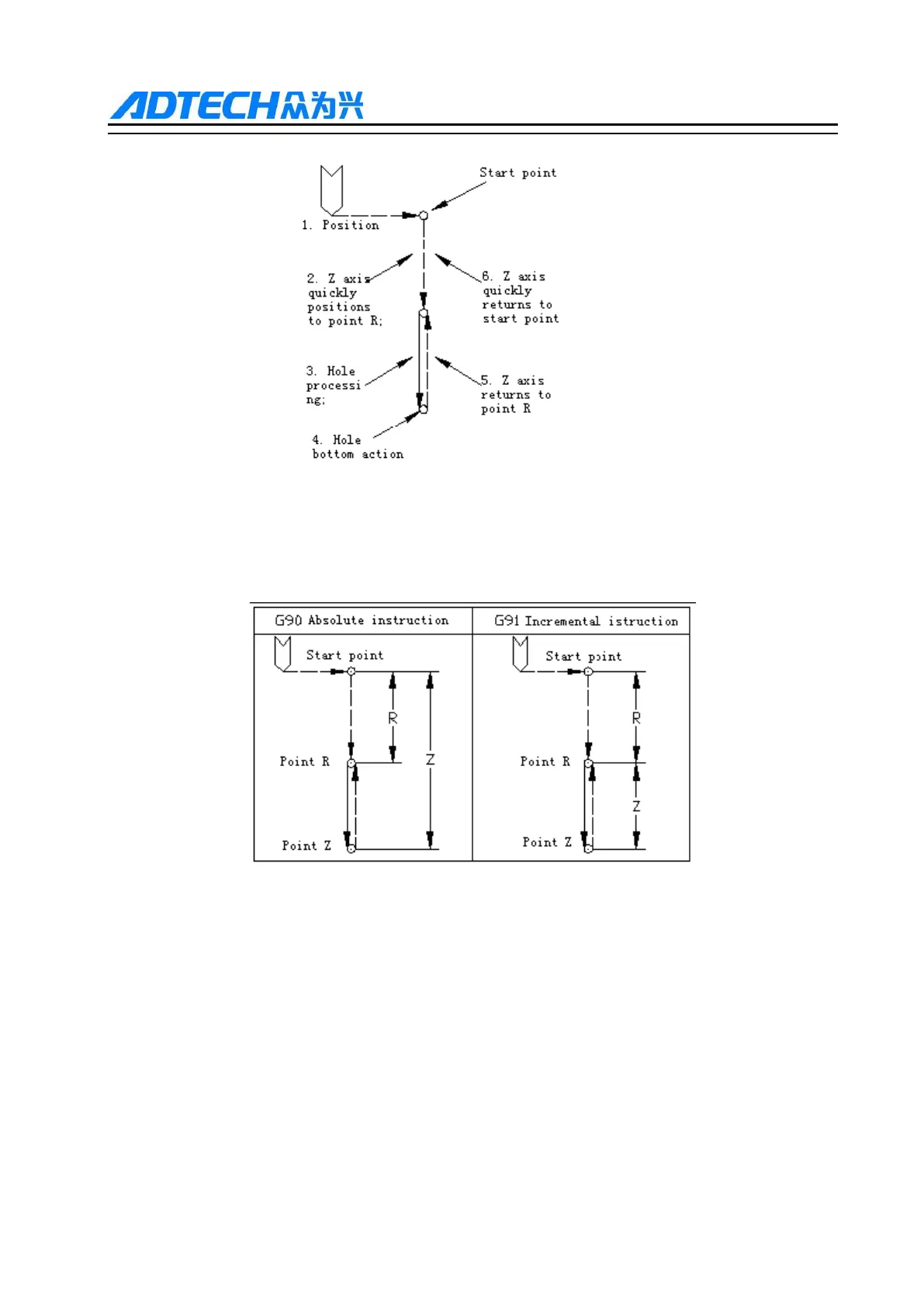

Six Steps of Hole Processing Fixed Cycle

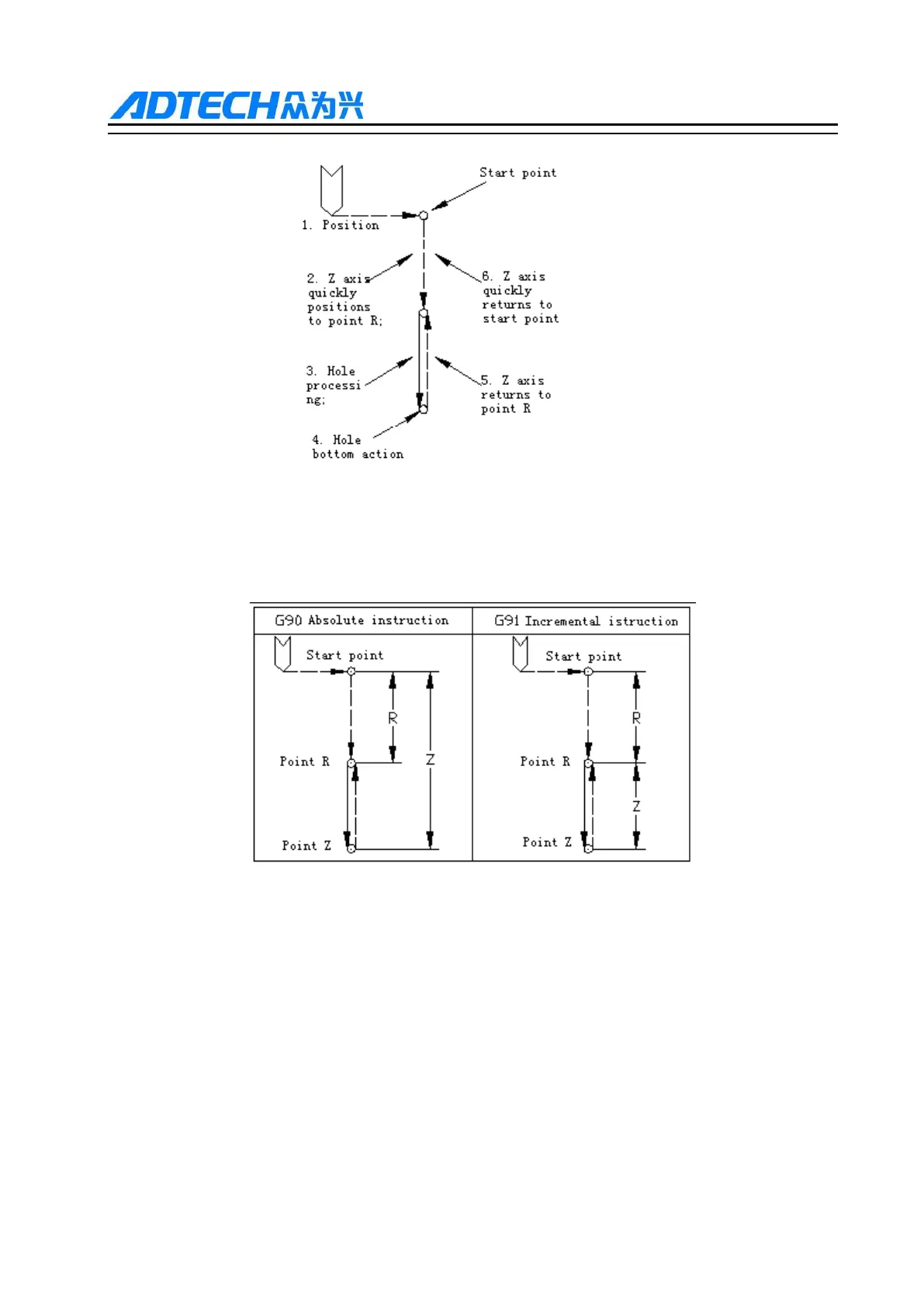

The instructions that have influence on the execution of hole processing fixed cycle instruction include

G90/G91 and G98/G99. Fig. 10.2 shows the effect of G90/G91 on hole processing fixed cycle instruction.

Effect of G90/G91 on Hole Processing

G98/G99 determines fixed cycle returns to point R or the start point after hole processing; in G98 mode, Z axis

returns to the start point after hole processing; in G99 mode, it returns to point R.

Generally, if the holes being processed are on a flat plane, we can use G99 instruction, because it will position

next hole after returning to point R in G99 mode; in general programming, point R is close to workpiece

surface, it will shorten part processing time; but if the workpiece surface has convex platform or tendon, the

tool and workpiece may collide if G99 is used; at this moment, G98 should be used to return Z axis to the start

point and then position next hole to ensure the safety. See the figure below.

Loading...

Loading...