Copyright © 1996 General Motors Corp. 6–9

REBUILD OF SUBASSEMBLIES

clutch trimmer valve 21; and springs 31 and 32 (if

present), stop 33, plug 30, and fourth clutch trimmer

valve 29. For models that do not have spring 32, dis-

card spring 31 and install new springs 31 and 32.

(8) If present, remove accumulator valve 28,

spring 27, and stop 26.

NOTE:

•

For AT 545 models, S/N 3210418516 through

3210419140 only, proceed with Step (9).

•

For all other models, skip Step (9) and proceed

with NOTE preceding Step (10).

(9) For AT 545 models S/N 321041856

through 3210419140 only, check the etched part num-

ber on trimmer valves 12, 16, 21, and 29. Replace any

incorrect P/N 23016686 trimmer valves at reassembly

with the correct P/N 23014097 trimmer valves.

NOTE:

Valve stop 39 and spacer 42 are spring-loaded and

must be restrained while retainer pins 36 are being

removed. (Valve stop 39 replaces two parts used in

earlier models.)

(10) Remove one retainer pin 36 from control

valve body 11. Remove spacer 42, spring 41, and 1–2

relay valve 40.

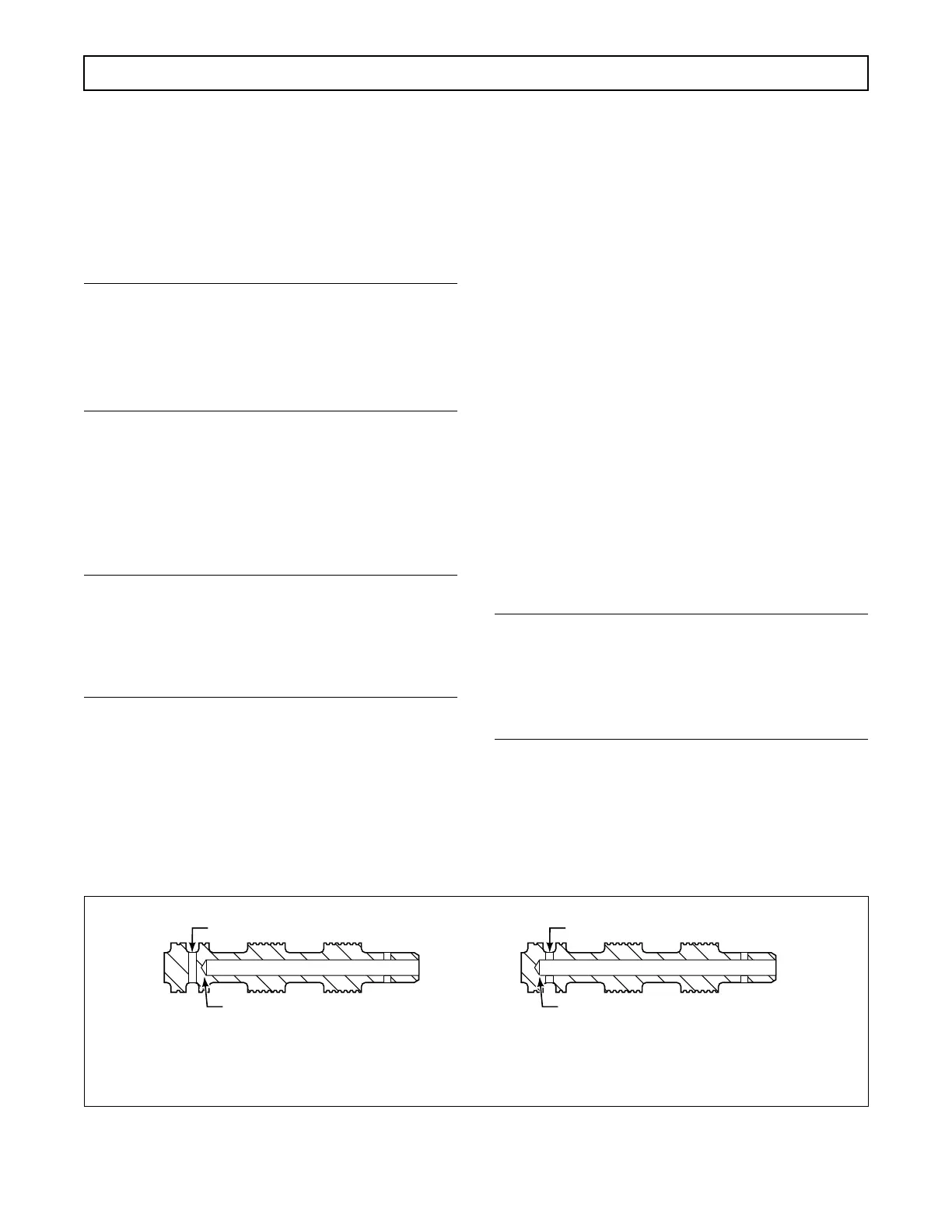

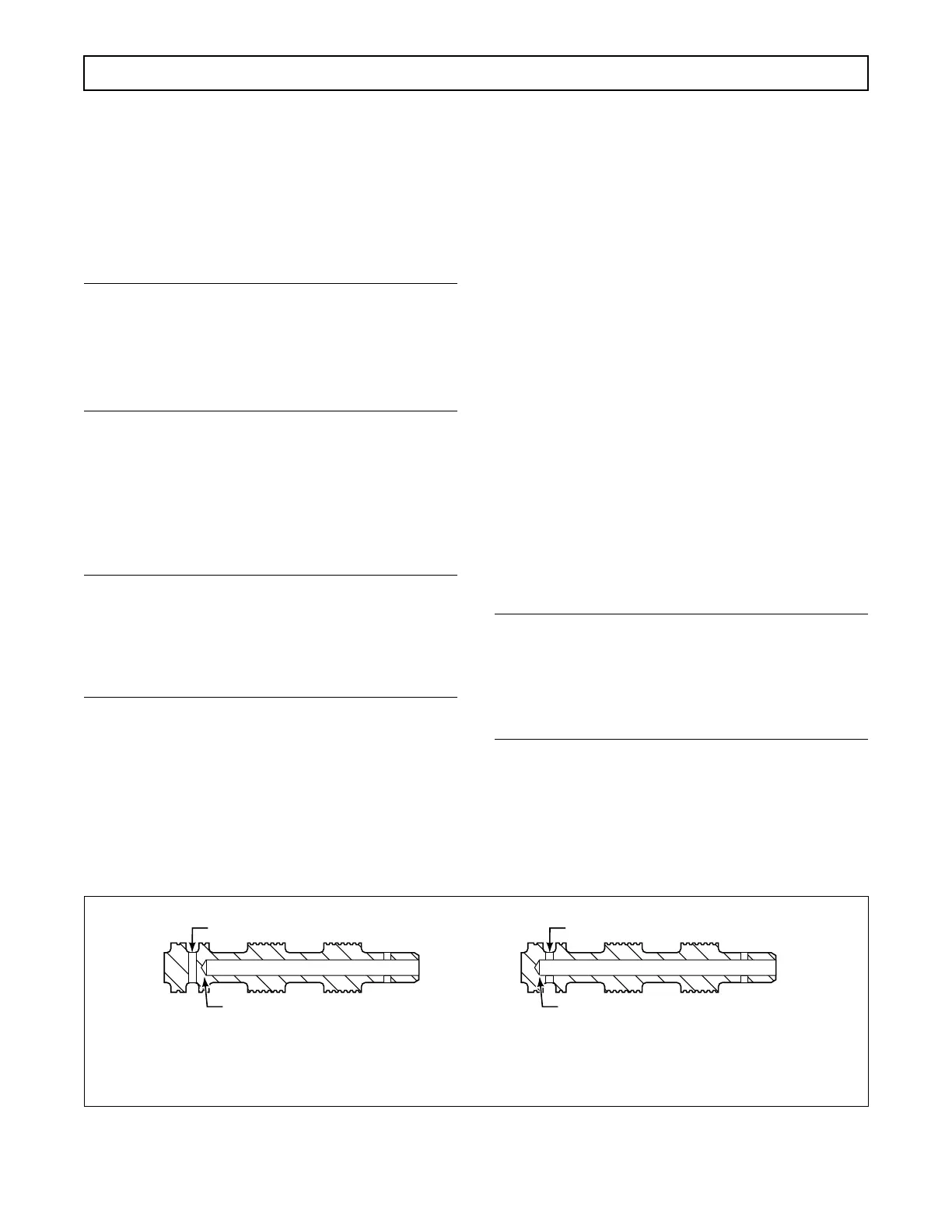

(11) Examine the interior bore of 1–2 relay

valve 40. If the configuration of the valve matches

View

A

, Figure 6–19, discard the valve and replace it

with a new valve at reassembly.

(12) Remove the other retainer pin 36 from

control valve body 11. Remove stop 39, spring 38, and

2–3 relay valve 37.

(13) Compress adjusting ring 51 and remove

retainer pin 52. Remove adjusting ring 51, washer 50,

plug 49 (if present), valve stop 48, valve spring 47, and

hold regulator valve 46 from the bore in control valve

body 11.

(14) Compress adjusting ring 58 and remove

retainer pin 59. Remove adjusting ring 58, stop 57,

spring 56 (if present), 1–2 modulator valve 55, 1–2

shift signal valve 54, and spring 83 (if present).

(15) Compress adjusting ring 64 and remove

retainer pin 65. Remove adjusting ring 64, stop 63,

spring 62, 2–3 modulator valve 61, and 2–3 shift sig-

nal valve 60.

NOTE:

Some units may have been field modified to prevent

the 3–4 shift. Take note of the position of retainer

pin 71 and stop 69; install parts in the same position

as removed.

(16) Compress adjusting ring 70 and remove

retainer pin 71. Remove adjusting ring 70, stop 69,

spring 68, 3–4 modulator valve 67, and 3–4 shift sig-

nal valve 66.

Figure 6–19. 1–2 Relay Valve

Insufficient Bore Depth Drilling

VIEW A

RELAY VALVE

INCORRECT DRILLING, DOES NOT

INTERSECT 0.125 in. (3.18 mm)

EXHAUST PORT

VIEW B

CORRECTLY DRILLED VALVE, DOES

INTERSECT 0.125 in. (3.18 mm)

EXHAUST PORT

0.125 in. (3.18 mm) EXHAUST PORT

Correct Bore Depth Drilling

0.125 in. (3.18 mm) EXHAUST PORT

V03135

Loading...

Loading...