2–14 Copyright © 1996 General Motors Corp.

AT 500, 1500 SERIES AUTOMATIC TRANSMISSIONS

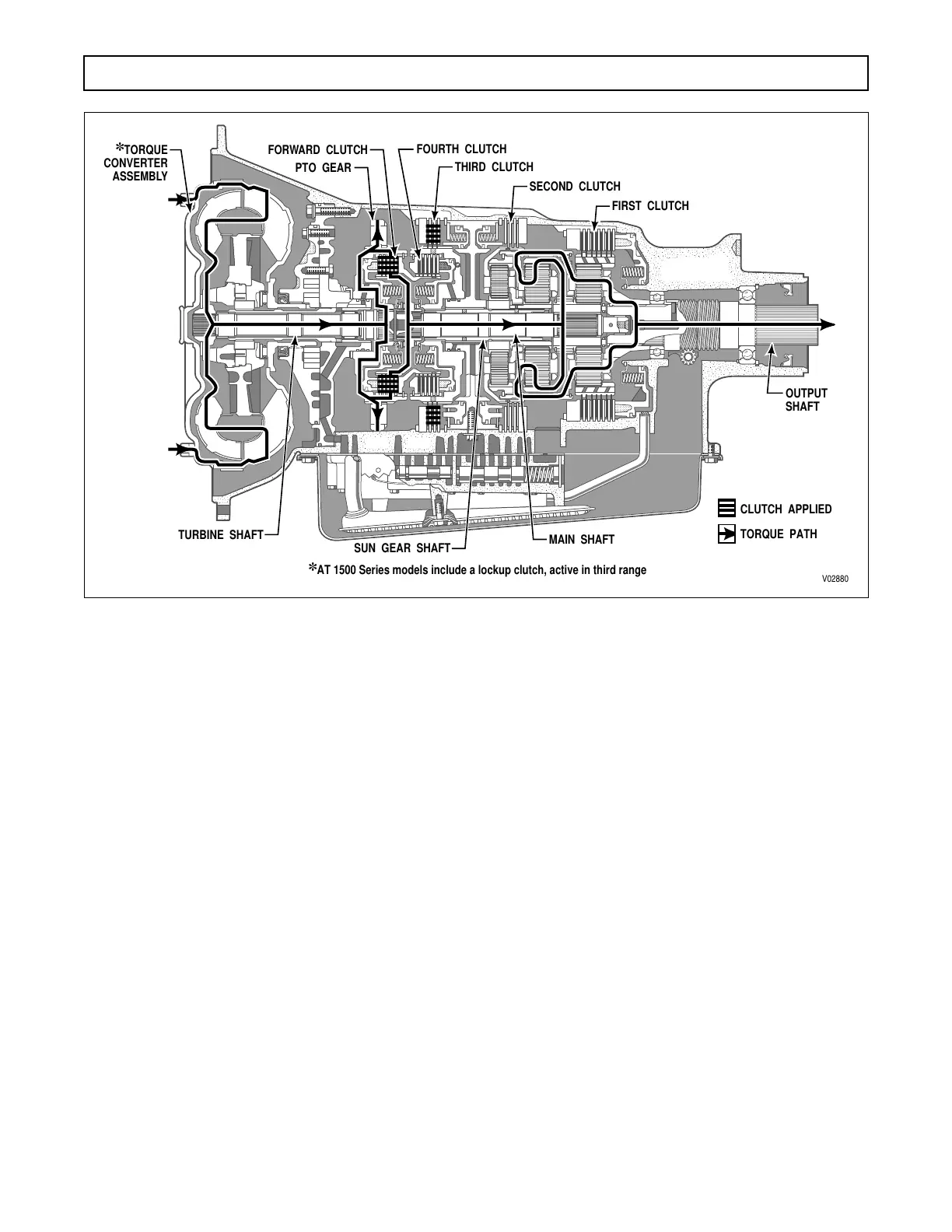

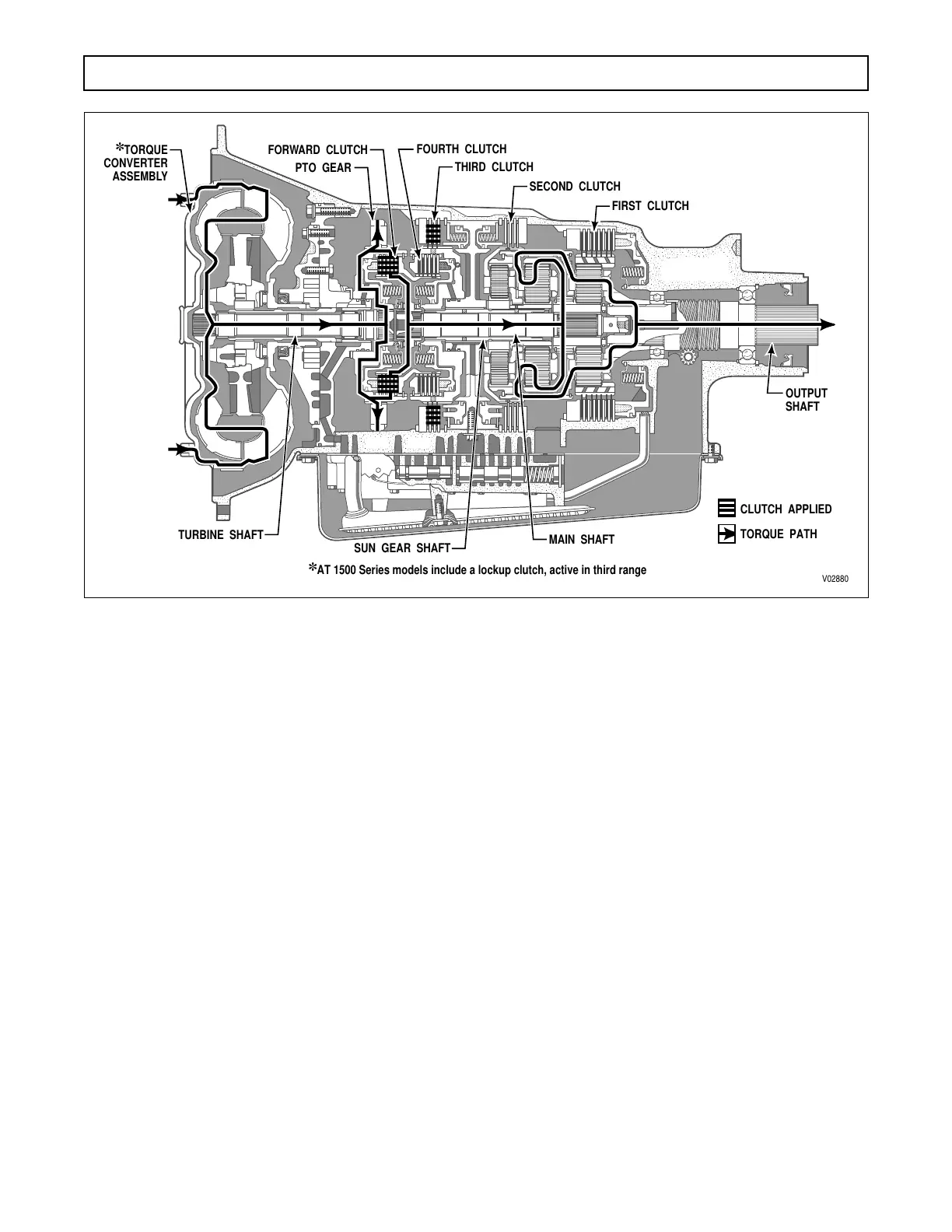

e. Third-Range Operation

(Figure 2–4)

. The

forward and the third clutches are applied. The third

clutch application anchors the sun gear shaft against

rotation, which, in turn, prevents the center sun gear

(splined to rear of shaft) from rotating. The forward

clutch application locks the turbine shaft and main

shaft together, to rotate as a unit. The rear sun gear is

splined to both the main shaft and the center ring gear

and rotates at turbine speed. With the center sun gear

stationary and the center ring gear rotating, the ring

gear drives the center planetary carrier pinions. This

carrier (and also the rear planetary carrier) is splined to

the planetary connecting drum and rotates with it as a

unit. The rear carrier is splined to the transmission out-

put shaft which produces an output ratio of 1.41:1.

f. Converter Operation

(AT 1500 Series Mod-

els).

During converter operation, 3–4 clutch feed

pressure is exhausted, allowing the lockup valve to

remain in the downward (unapplied) position. Main

overage flow is routed through the lockup valve to

the space between the turbine and stator shafts. From

there, fluid passes through slots in the turbine hub to

an area between the torque converter cover and pis-

ton. Converter-in pressure moves the piston away

from the reaction surface and provides the fluid nec-

essary for proper filling of the torque converter ele-

ments. Fluid exhausts through slots in the stator and

is sent to the cooler circuit.

g. Lockup Operation

(AT 1500 Series Models).

After the 2–3 upshift has occurred, main pressure be-

gins to shift the lockup valve upward. As the lockup

shift is made, three simultaneous changes occur: con-

verter-in pressure is exhausted, eliminating the sepa-

rating force between the converter cover and piston;

main overage is routed directly to the cooler circuit;

and 3–4 clutch feed pressure is directed to the torque

converter creating a pressure differential across the

lockup piston. As a result, 3–4 clutch feed pressure ap-

plies the lockup clutch, providing increased operating

efficiency.

Figure 2–4. Third Range Power Flow

;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;

;;;;;;;;;

;;;;;;;;;

;;;;;;;;;

;;;;;;;;;

V02880

TURBINE SHAFT

SUN GEAR SHAFT

PTO GEAR

FORWARD CLUTCH

THIRD CLUTCH

SECOND CLUTCH

FIRST CLUTCH

FOURTH CLUTCH

✽

TORQUE

CONVERTER

ASSEMBLY

MAIN SHAFT

TORQUE PATH

✽

AT 1500 Series models include a lockup clutch, active in third range

CLUTCH APPLIED

OUTPUT

SHAFT

Loading...

Loading...