Copyright © 1996 General Motors Corp. 6–17

REBUILD OF SUBASSEMBLIES

(5) Coat the OD of a new non-prebored re-

placement bushing 18 (Foldout 7,B) with Loctite

®

601

sleeve retainer, or equivalent. Install bushing 18 into

the stator shaft with J 23614-A to a depth of flush to

0.005 inch (0.127 mm) below the end of the shaft (Fig-

ure 6–27). Remove any excess Loctite

®

from the shaft

housing.

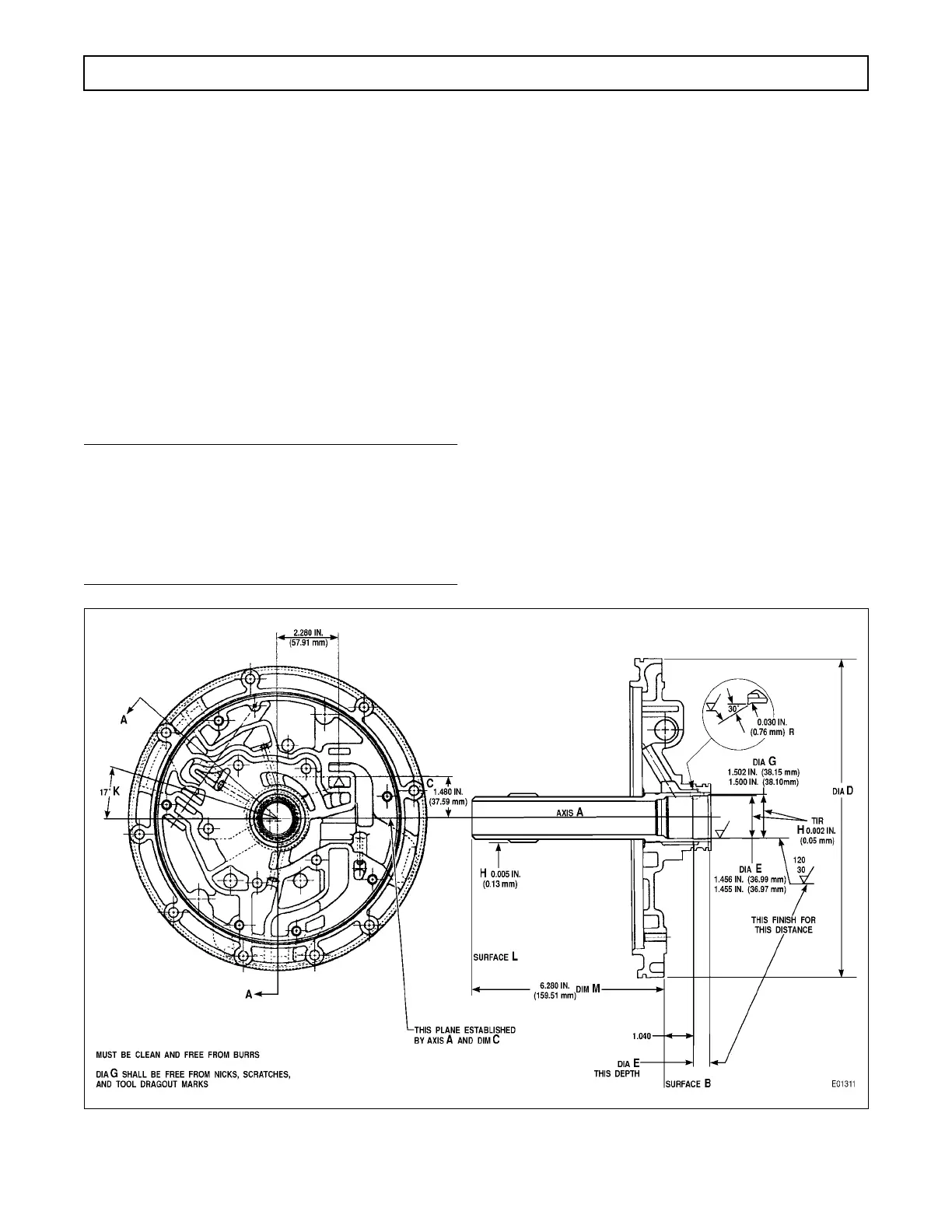

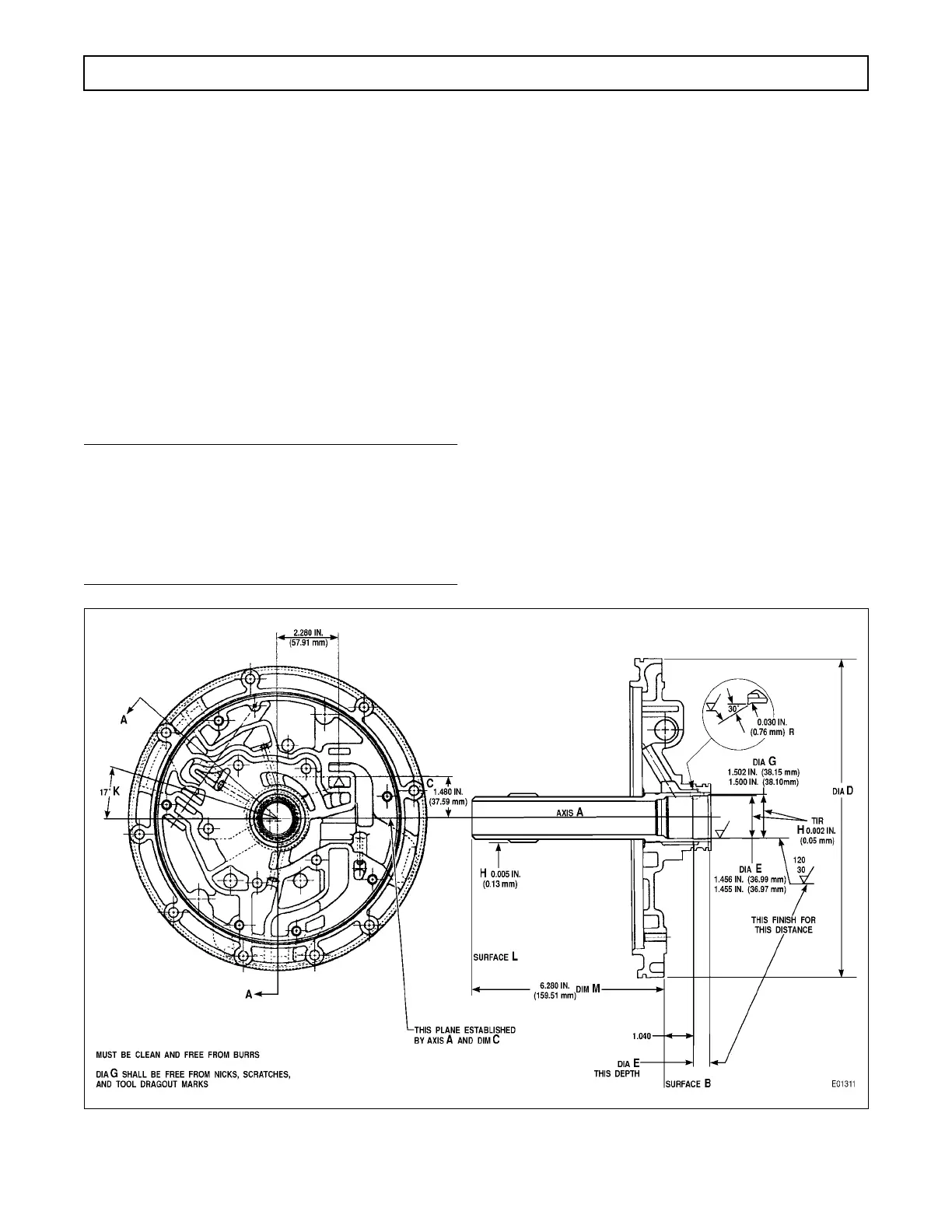

(6) Machine the bushing to the diameter and

microfinish specified (Figure 6–25) while maintaining

TIR not to exceed 0.003 inch (0.076 mm).

(7) Thoroughly clean the assembly of any

metal chips and dirt, being careful to clean all pas-

sages in the front support.

c. Pump Gear Clearance Check (Foldout 7,B)

NOTE:

Proper end play and side clearance of the oil pump

gears must be established before the pump is assem-

bled. Remove all nicks and burrs from the pump

and gear surfaces to facilitate accurate dial indica-

tor readings.

(1) Position oil pump body assembly 6, flat

side upward. Install drive gear 10 into pump body as-

sembly 6, so the internal tangs of the gear are facing

upward. Install gear 9 into the pump body 6 so that

the side of gear 9 marked with a diamond is down-

ward.

(2) Position dial indicator J 26857 on the

pump body as shown in Figure 6–28. Zero the dial while

the stylus (plunger) is contacting the pump body face.

(3) Without disturbing the dial setting, slide

the indicator to the driven gear (Figure 6–29). While

holding the indicator in position, record the reading. If

the clearance is not within 0.0008–0.0022 inch

(0.020–0.056 mm) on a new gear or 0.0008–0.0026

inch (0.020–0.066 mm) on a used gear, replace the

gear and repeat Steps (2) and (3).

(4) Slide the indicator to the drive gear (Fig-

ure 6–30). While holding the indicator in position,

record the reading. If the clearance is not within

0.0008–0.0022 inch (0.020–0.056 mm) on a new gear

or 0.0008–0.0026 inch (0.020–0.066 mm) on a used

gear, replace the gear and repeat Steps (2) and (4).

Figure 6–26. Installation of Stator Shaft (AT 1500 Series)

Loading...

Loading...