6–26 Copyright © 1996 General Motors Corp.

AT 500, 1500 SERIES AUTOMATIC TRANSMISSIONS

NOTE:

Earlier model transmissions use a piston seal on

fourth clutch housing 13. If present, discard the

housing seal. A fourth clutch housing seal should

not be used during assembly. Use only the two seals

on the piston.

(6) Refer to Paragraph 4–5p and Figure 6–45

for housing check ball specifications. Remove the ball

from the fourth clutch housing only if replacement is

necessary. If necessary, clear the bore of the staked

metal and remove the ball.

b. Checking Clutch Pack Clearance

NOTE:

• Two methods of establishing proper clutch clear-

ance are explained and illustrated. The first

method, Steps (1) through (6), is by direct mea-

surement using a go/no-go gauge. The second

method is by stack dimension computation

(Paragraph 6–17). This method may be more

convenient when assembly line overhaul practic-

es are used.

• If piston 8 must be replaced, be sure that the

identification (A, B, C, EF, E, or DE) on the new

piston is the same as that on the old piston.

(1) Install the piston, without sealrings, into

the clutch housing assembly until the piston bottoms

against the housing.

(2) Beginning with an external-tanged plate,

alternately install five external-tanged clutch plates 4

(Foldout 9,A) and five internal-splined clutch plates 3

onto piston 8.

(3) Install clutch backplate 2, flat side first,

onto the last clutch plate 3 installed. Install snapring 1

into housing 13.

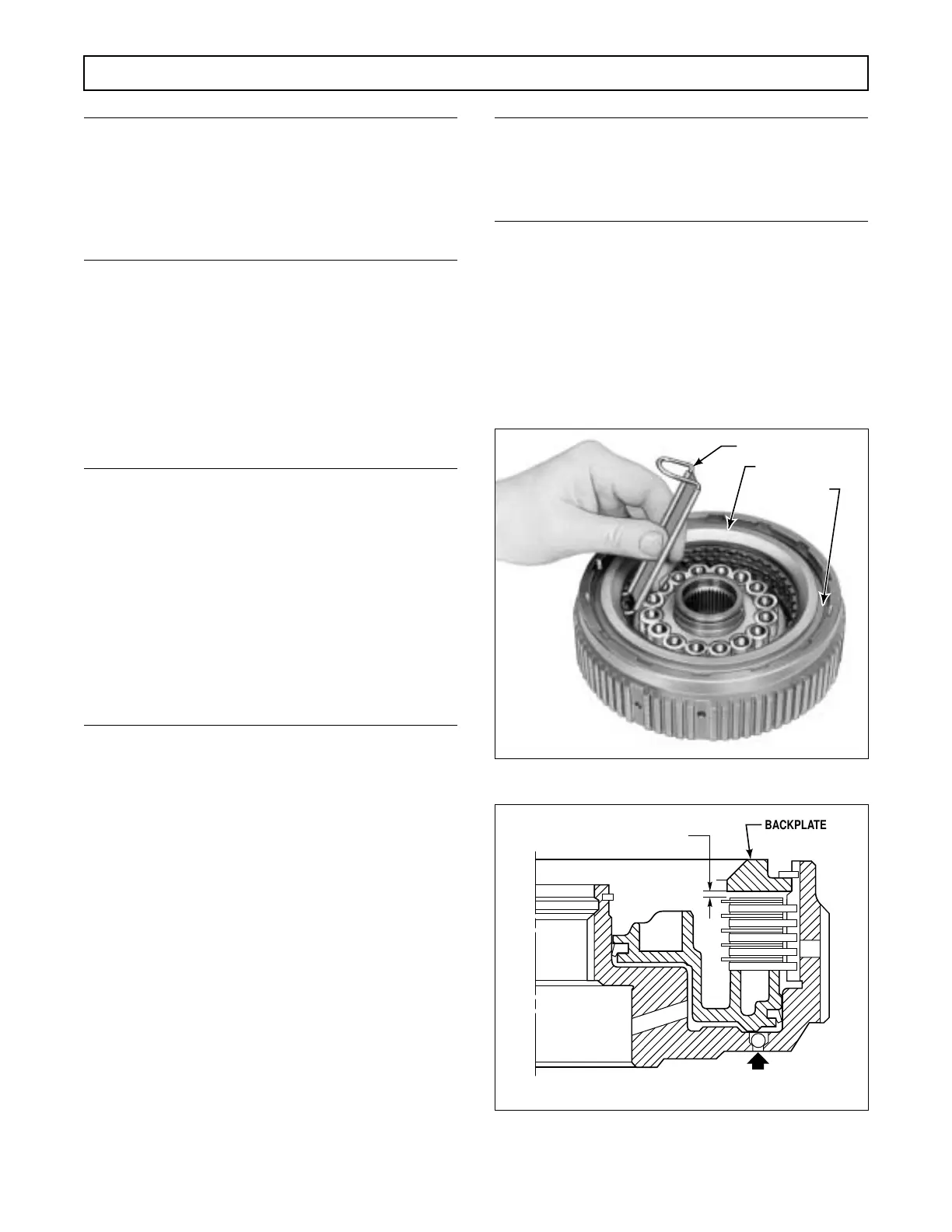

(4) While holding backplate 2 firmly against

snapring 1, use clutch clearance gauge J 23619-01 to

measure the clearance between the backplate and the

clutch plate (Figure 6–44). The smaller end of the

gauge must insert between the backplate and the first

clutch plate. The larger end must not.

NOTE:

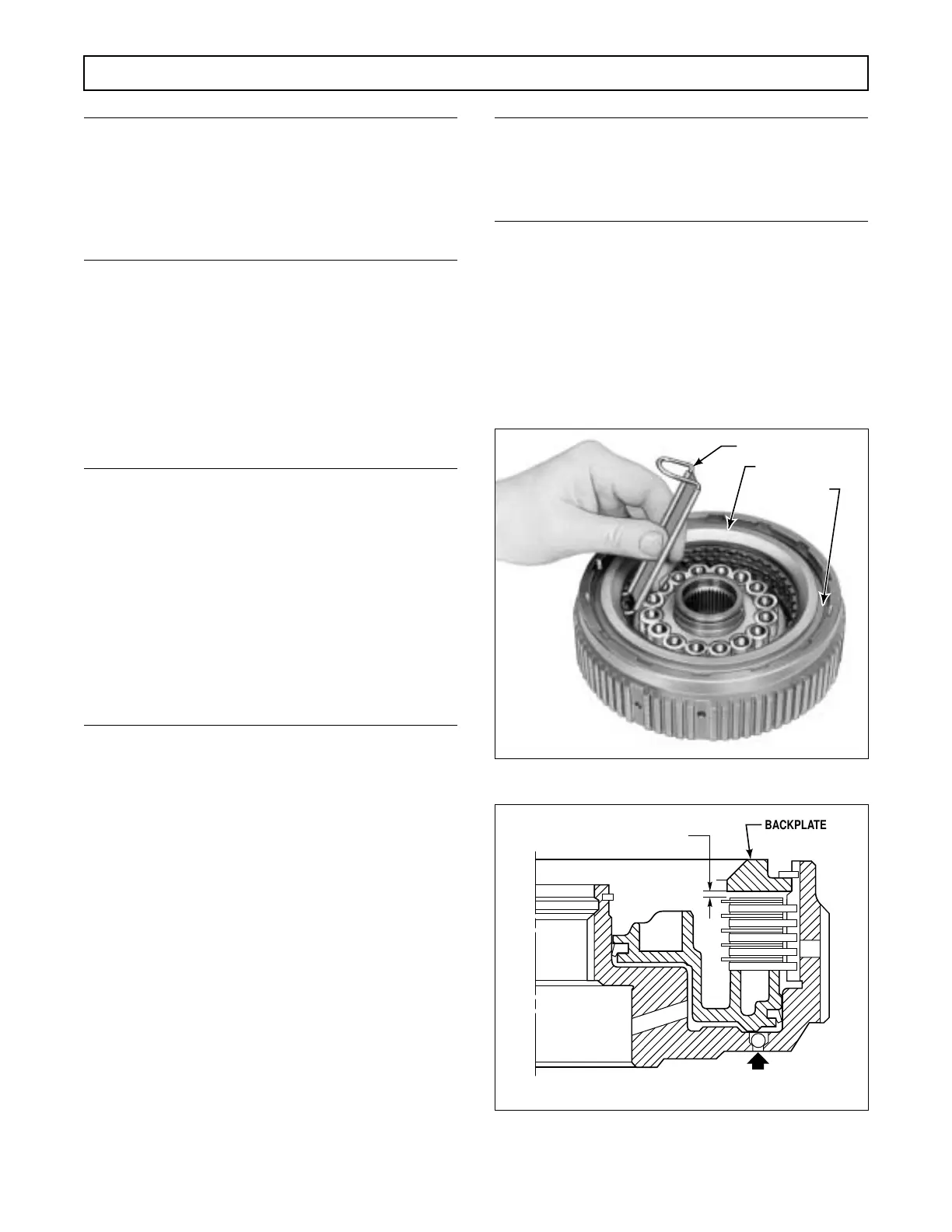

If the J 23619-01 gauge is not available, measure the

clearance between the backplate and the first clutch

plate (Figure 6–45).

(5) If the clutch running clearance is not

within the specified limits, remove snapring 1, back-

plate 2, and clutch plates 3 and 4. Replace clutch

plates 3 and 4 with new plates or replace piston, as re-

quired, to establish the proper running clearance. Re-

fer to wear limits, Section 8, to determine the plates

which should be replaced.

Figure 6–44. Checking Fourth Clutch Clearance

Figure 6–45. Fourth Clutch Clearance Check Point

H02951

J 23619-01

BACKPLATE

FOURTH

CLUTCH

ASSEMBLY

V02952

Minimum Axial Movement

0.040 in. (1.02 mm)

Check clearance here

0.0765 – 0.1265 in.

(1.944 – 3.213 mm)

Loading...

Loading...