6–20 Copyright © 1996 General Motors Corp.

AT 500, 1500 SERIES AUTOMATIC TRANSMISSIONS

(14) Install front support assembly 16 onto

pump body assembly 5, aligning the bolt holes.

(15) Install six (eight, some models)

5

⁄16-18 x

1 inch bolts 11 (Foldout 7,B) and new rubber coated

washers 12 into the pump side of the oil pump assem-

bly. Tighten the bolts finger tight.

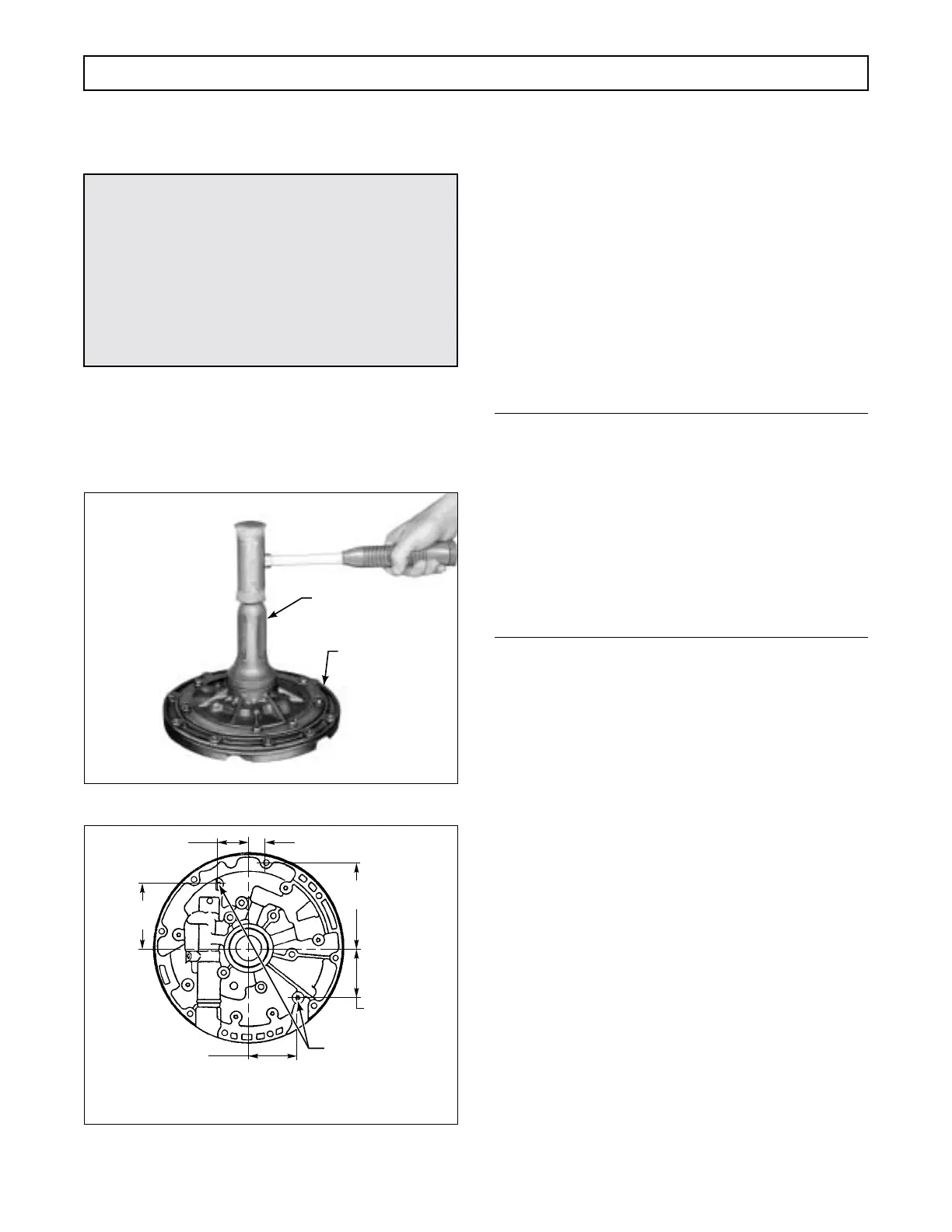

Figure 6–33. Installing Oil Pump Seal

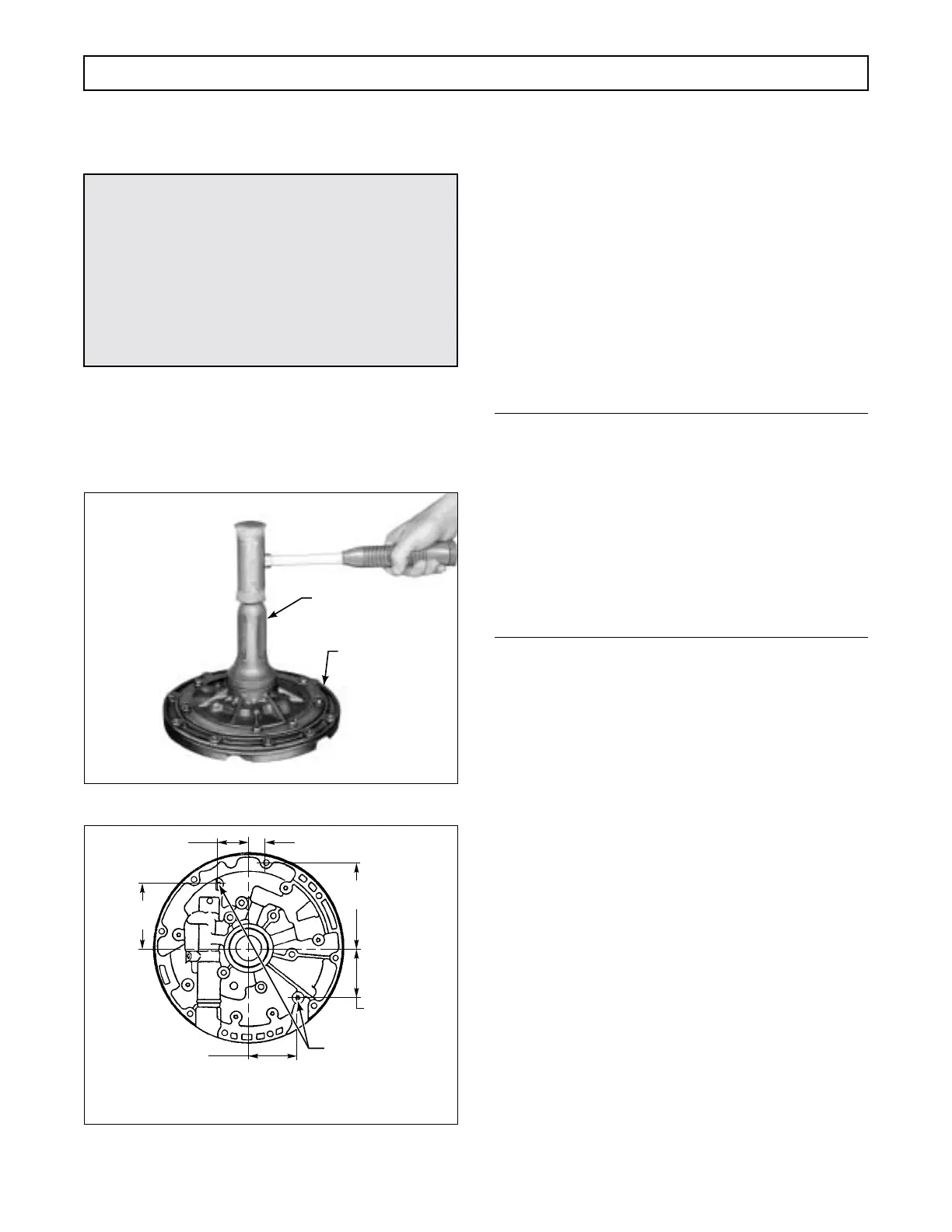

Figure 6–34. Rework Dimensions for Front Support

(16) Install bolts 28 and 29 as were removed.

(For different models, the length may differ).

(17) Tighten all the

5

⁄16-18 bolts to 15–20 lb ft

(20–27 N

.

m).

(18) Lubricate and install sealring 13 onto the

outer diameter of front support 21.

6–10. FORWARD CLUTCH AND

TURBINE SHAFT ASSEMBLY

a. Disassembly

NOTE:

• For earlier models with PTO gear and without

retarder, proceed with Step (1).

• For later models with PTO gear and without re-

tarder, skip Step (1) and proceed with Step (2)

• For models without PTO gear and without re-

tarder, skip Steps (1) through (8) and proceed

with Step (9).

• For models with retarder, skip Steps (1) through

(7) and proceed with Step (8).

(1) For earlier models with PTO gear and

without retarder, place forward clutch and turbine

shaft assembly 7 (Foldout 8) on the work table, with

the shaft upward. Using a screwdriver, remove

snapring 3 that secures PTO drive gear 4 to forward

clutch housing 9. Remove gear 4 and snapring 5. Skip

Steps (2) through (7) and proceed with Step (8).

(2) For later models with PTO gear and

without retarder, locate the snapring gap by looking

between the tips of the PTO gear internal splines and

the roots of the housing splines. Light can be seen in

the gap area.

(3) At the opening (omitted housing spline)

closest to the snapring gap, insert a small screwdriver

and push the snapring toward the housing until a

5

⁄64 x

0.020 inch (2 x 0.5 mm) steel strip, 2 to 3 inches (50–75

mm) long can be inserted in the root of the housing

spline nearest the snapring gap (Figure 6–35).

(4) Repeat Step (3) at the opposite side of

the snapring gap.

CAUTION:

Because of transmission fluid leakage, a six-bolt

support should never be used with an eight-bolt

pump body. However, the six-bolt support may

be modified by tapping two additional holes (Fig-

ure 6–34). Any other combination of parts (6-

hole support with 6-hole body, 8-hole support

with 8-hole body, or 8-hole support with 6-hole

body) is acceptable without modification.

H02940

PUMP BODY

J 21359-A, AT 500 SERIES

(J 39757, AT 1500 SERIES)

L02941

Drill and tap to 0.3125-18

UNC-2B two (2) places,

locate within 0.010 in.

(0.25 mm) radius of the

true position given

3.740 in.

(94.99 mm)

5.036 in.

(127.91 mm)

2.900 in.

(73.66 mm)

1.760 in.

(44.70 mm)

2.920 in.

(74.17 mm)

0.980 in.

(24.89 mm)

REAR VIEW

Loading...

Loading...