Copyright © 1996 General Motors Corp. 6–21

REBUILD OF SUBASSEMBLIES

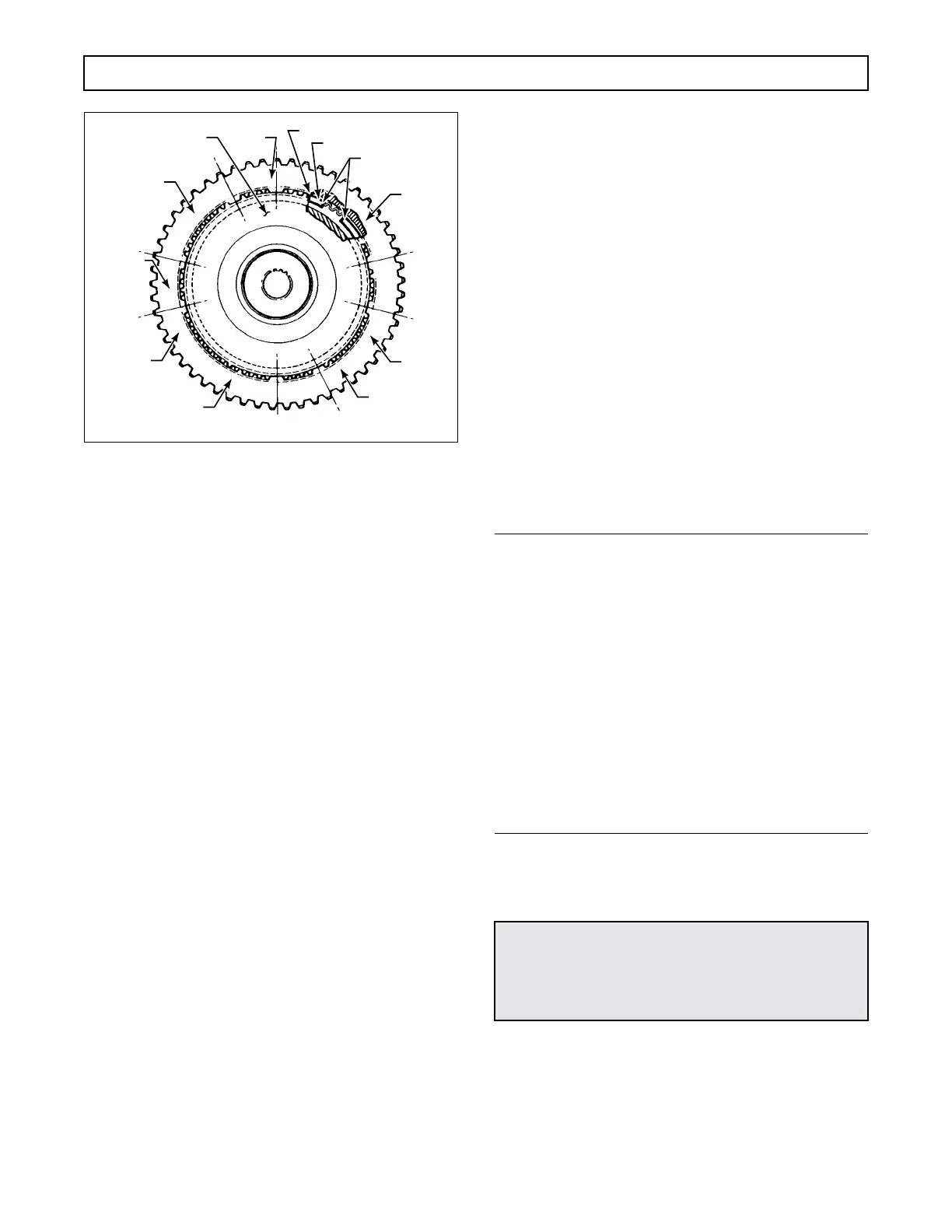

Figure 6–35. Removing PTO Gear From

Forward Clutch Housing

(Later Models Without Retarder)

(5) Using the screwdriver in the openings

(omitted splines) as required to depress the snapring,

place steel strips in housing spline roots as necessary

to hold the snapring inward. Work from the strips first

installed to a point opposite the gap.

(6) Use as many strips as required (8 should

be sufficient) and place them at positions that will hold

the snapring entirely clear of the PTO gear splines.

(7) When the snapring clears the PTO gear

splines, light can be seen through all spaces (except

those holding steel strips) between PTO gear spline

tips and housing spline roots. Remove the gear.

(8) For models with retarder, remove two

hook-type sealrings 12 (Foldout 8) from forward

clutch housing 14.

(9) Remove hook-type sealring 2 (Foldout 8)

from the turbine shaft. Turn the assembly over.

(10) Using a screwdriver, remove snapring 30

from the forward clutch housing. Remove fourth

clutch drive hub 29 from the housing.

(11) Remove forward clutch hub 26 from the

housing.

(12) Inspect forward clutch hub 26 closely on

high mileage transmission units down for overhaul.

Over an extended period of operation, a wear pattern

at the internal spline of the hub may occur. This wear

ring, the result of contact with the transmission main

shaft, is so uniform in shape that it is often overlooked.

Replace this hub where this condition exists. In most

instances, wear of adjacent thrust washers should alert

you to inspect the forward clutch hub for abnormal

wear. Although the transmission may be functioning

properly prior to overhaul, the clutch hub should be re-

placed when wear exists. Reuse of a distressed hub

with new washers will accelerate washer wear and will

not duplicate the original durability and service life.

(13) Remove thrust bearing race 25, thrust

needle bearing 24, and thrust bearing race 23 from the

hub of the forward clutch housing.

(14) Remove five external-tanged clutch

plates 27 and five internal-splined clutch plates 28

from the clutch housing.

NOTE:

• Later models have a wave plate in the forward

clutch next to piston 19 (Foldout 8) which im-

proves the neutral-to-range shift quality. A kit is

available that contains parts required to make

this change. Be sure to confirm all interchange-

ability factors by referring to Parts Catalog

SA1235 or SA2126. Both forward- and fourth-

clutch assemblies have various part numbers af-

fected by this upgrade. Refer also to the latest

version of Service Information Letter 3-TR-93.

• Models that have the wave plate in the forward

clutch assembly use a clutch housing marked

with an identification groove (Figure 6–36).

(15) Place the forward clutch assembly in a

press with the spring retainer upward (Figure 6–37).

(16) Place compressor tool J 23616 on the

spring retainer (Figure 6–37). Compress the retainer

until the snapring is free. Using snapring pliers, re-

move the snapring. Release the press and remove the

assembly.

L02942

FORWARD

CLUTCH HOUSING

PTO

GEAR

SHIM 2

SHIM 1

SHIM 3

SHIM 5

SHIM 7

SHIM 8

SHIM 6

SHIM 4

SNAPRING

SNAPRING

GAP

CAUTION:

When removing the forward clutch snapring, do

not allow the spring retainer to catch in the

snapring groove.

Loading...

Loading...