6–34 Copyright © 1996 General Motors Corp.

AT 500, 1500 SERIES AUTOMATIC TRANSMISSIONS

a. Inspection

(1) Visually inspect the planetary carrier as-

sembly for evidence of excessive wear, indications of

overheating, damage, or heavy metal contamination.

(2) Check the end play of the planetary

carrier pinions. With the washer held flat, insert a

feeler gauge between the carrier and thrust washer.

End play must be within 0.008–0.031 inch (0.20–

0.79 mm).

NOTE:

• Do not disassemble the carrier assembly unless

parts replacement is necessary. Failure of one pin-

ion requires replacement of the entire matched

pinion gear set, pinion pins, and bearings.

• Depending upon the amount of labor (machining

the bushing), time, part replacement, and extent

of rework, complete replacement of the assembly

may be more practical.

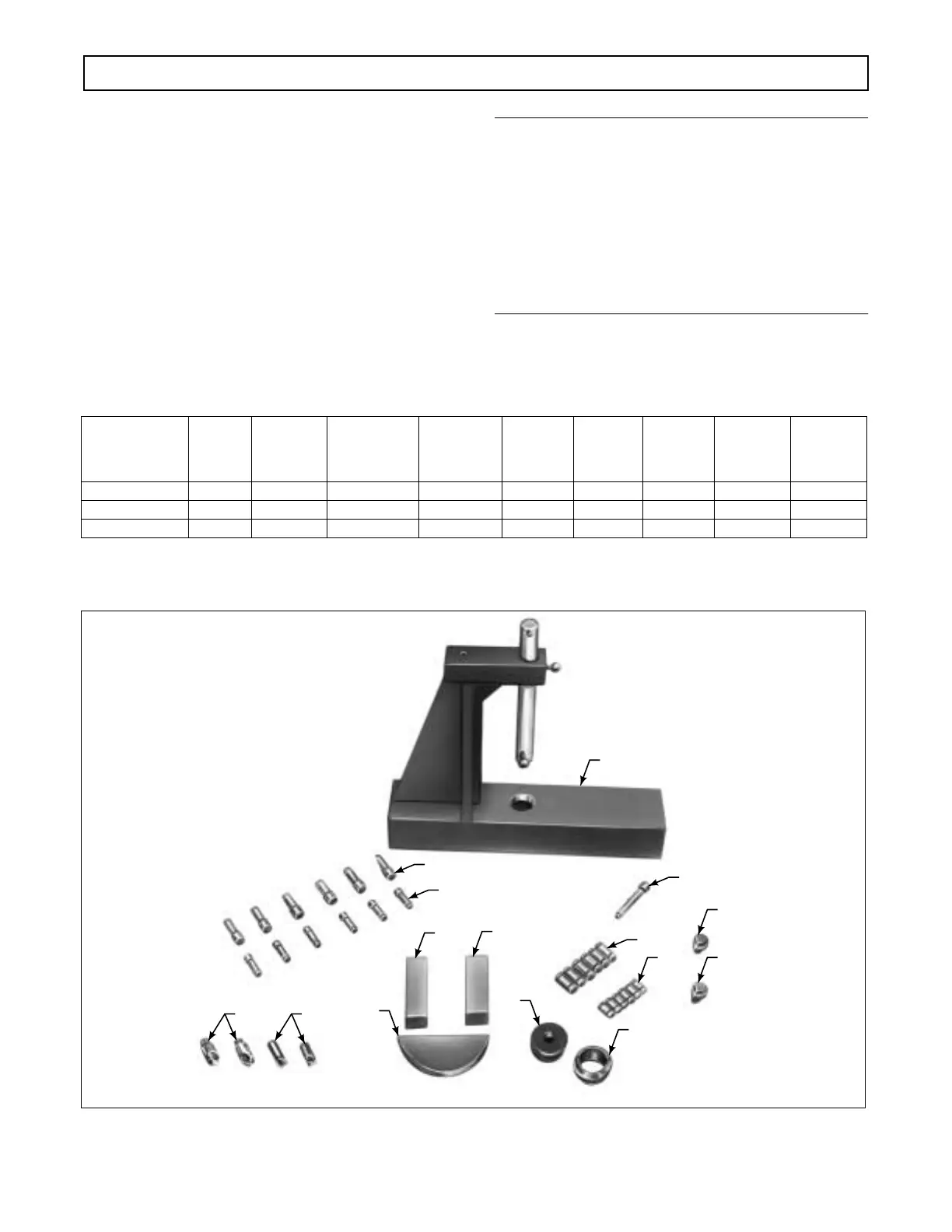

Planetary Carrier Assembly Rebuild Tool Chart

Note — All tools in this chart have a basic number (J 25587) and a suffix. Only the suffix is shown below.

The figures in parentheses are quantities required.

Tools in the chart above are components of Planetary Rebuilding Kit J 25587-01. Refer to Paragraph 4–2b.

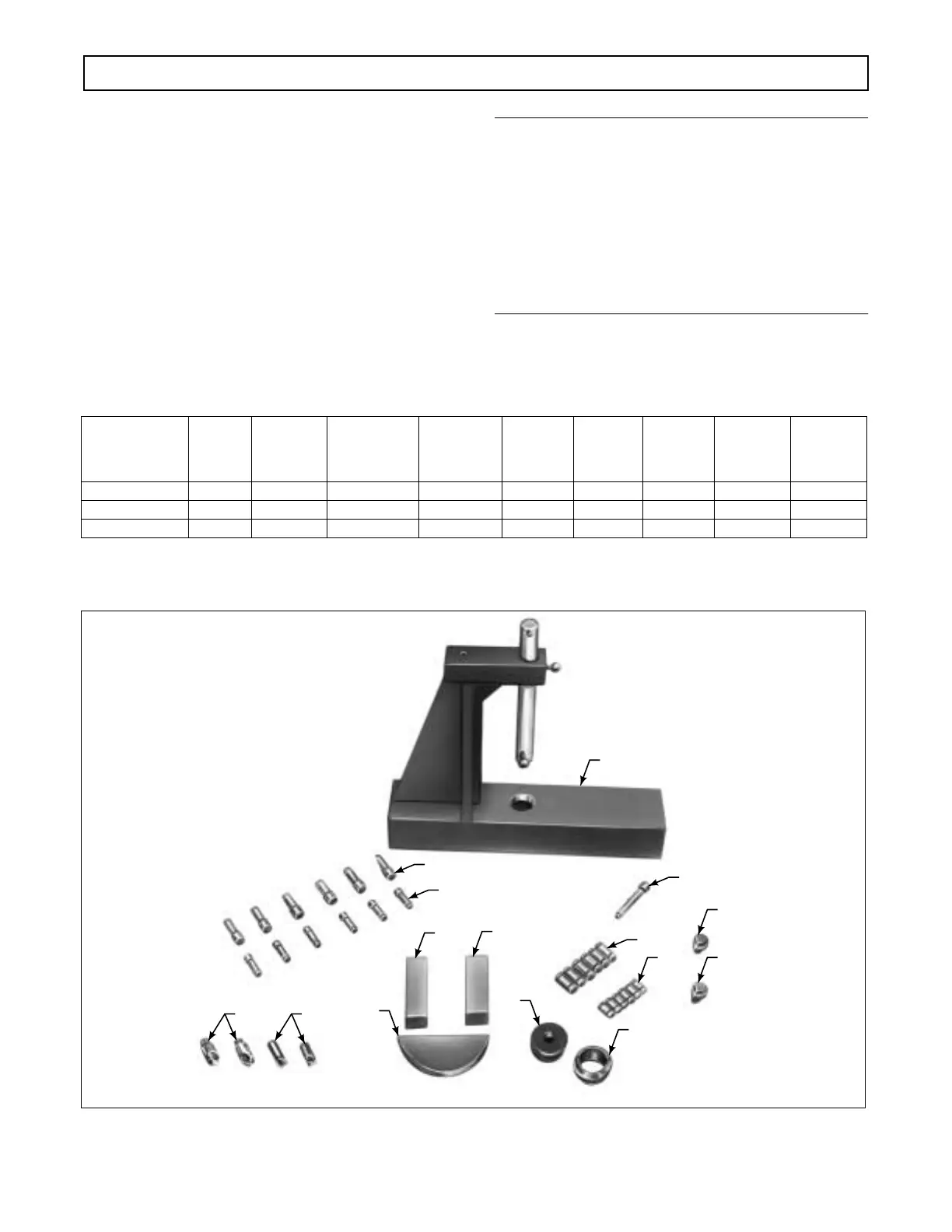

Figure 6–59. Planetary Rebuild Tool Identification

Planetary

Carrier

Assembly

Support

Block

Pin

Remover

Pin Remover

and Installer

Adapter

Pin Remover

and Installer

Spacer

Loading

Pin

Guide

Pin

Pin

Installer

Swaging

Tool

Holder

Swaging

Tool

Front –4 –16 –22 (4) –50 (4) –14 –17 –27 (2)

Center –1 –16 –20 (4) –49 (4) –10 –17 –25 (2)

Rear –3 –16 –2 –6 –20 (4) –49 (4) –10 –17 –25 (2)

H02966

–4

–2

–22

–10

–1

–14

–3

–25 –27

–6

–17

–50

–20

–16

–49

Loading...

Loading...