Copyright © 1996 General Motors Corp. 3–21

PREVENTIVE MAINTENANCE

PREVENTIVE MAINTENANCE

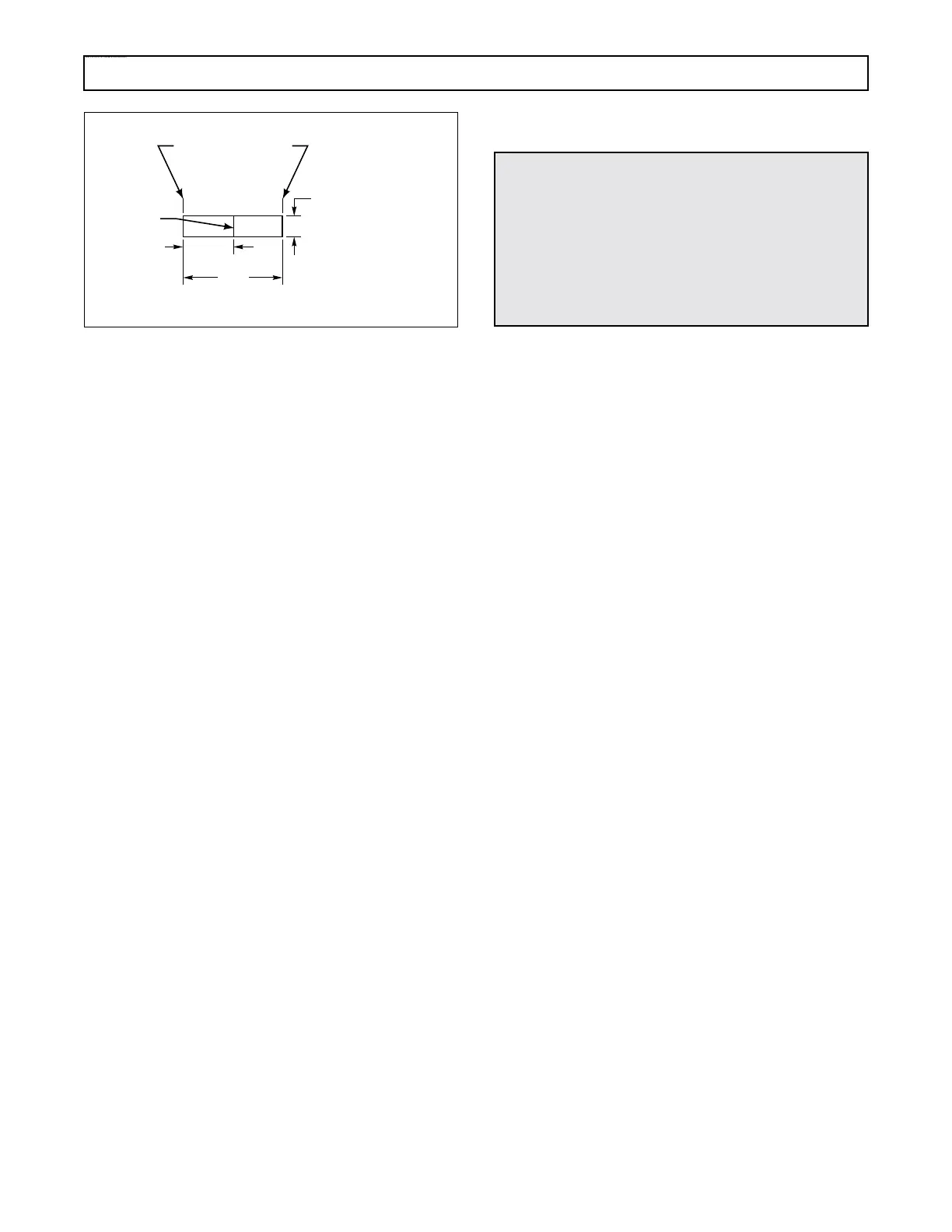

Figure 3–10. Gauge for Comparing Vacuum Modulators

(4) Sleeve alignment check. Roll the main

body of the modulator on a flat surface and observe the

sleeve for concentricity to the can. If the sleeve is con-

centric and the plunger is free, the modulator is ac-

ceptable.

(5) A modulator passing all checks in Steps

(1) through (4) should be an acceptable part.

3–18. TROUBLESHOOTING — BEFORE

REMOVAL AND DURING

OPERATION

a. Determine Cause of Trouble

(1) If the inspections in Paragraph 3–17 do

not reveal the cause of the problem and the vehicle is

operable, further troubleshooting is necessary. Do not

remove the transmission from the vehicle until the

cause of the trouble listed in the troubleshooting chart

is checked.

(2) The engine and transmission must be re-

garded as a single package during troubleshooting. A

thorough study of the description and operation of the

components and hydraulic system will be helpful in

determining the cause.

b. Proper Engine Tuning. In order to make a

thorough test of the transmission while it is mounted

in the vehicle, be sure that the engine is properly tuned

and the fluid level in the transmission is correct. Refer

to Paragraph 3–5 for checking fluid level.

c. Hydraulic Pressure Checking Procedures

(1) Table 3–10 is for checking main pressure

on transmissions having demodulated main pressure.

(2) Table 3–11 is for checking main pressure

on transmissions having modulated main pressure.

(3) Table 3–12 is for checking retarder

pressure.

(4) The pressure check points are shown in

Figures 3–11, 3–12, and 3–13.

3–19. TROUBLESHOOTING —

TRANSMISSION REMOVED

FROM VEHICLE

When the malfunction of a transmission is not ascer-

tained by tests or inspections before removal from

the vehicle, the transmission may be mounted in a

test stand and checked (if a test stand is available).

Particular attention must be given to proper fluid

level and to proper linkage adjustment in every trans-

mission test.

3–20. TROUBLESHOOTING

PROCEDURES

Table 3–13, Troubleshooting Chart, lists possible

causes of transmission troubles and their remedies.

Capital letters indicate the symptom; numerals follow-

ing the symptom indicate several possible causes; cor-

responding numerals in the right column indicate rem-

edies for the causes.

ENDS TO BE SQUARE

WITHIN

1

⁄64 in.

(0.40 mm)

SCRIBED

LINE

V02886

1

⁄2 in.

(12.7 mm)

3

⁄8 in. (131.03 mm) TO

13

⁄32 in. (9.53 mm)

ROUND OR FLAT STOCK

1 in.

(25.4 mm)

WARNING!

Observe safety precautions during hydraulic

pressure check procedures. All personnel must

stand clear of the vehicle. Take precautions

against movement of the vehicle. Be sure that

gauges (vacuum, pressure, tachometer) have ex-

tended lines so that they can be read from inside

the vehicle.

Loading...

Loading...