3–20 Copyright © 1996 General Motors Corp.

AT 500, 1500 SERIES AUTOMATIC TRANSMISSIONS

(3) Modulator comparison check. Using a

comparison gauge (Figure 3–10), compare the load of a

known good modulator with the assembly in question.

• Install a modulator that is known to be

acceptable on either end of the gauge.

• Install the modulator in question on the

opposite end of the gauge.

• Holding the modulators in a horizontal posi-

tion, bring them together under pressure until

either modulator sleeve end just touches the

line in the center of the gauge. The gap be-

tween the opposite modulator sleeve end and

the gauge line must be 0.062 inch (1.57 mm)

or less. If the distance is greater than this

amount, replace the modulator in question.

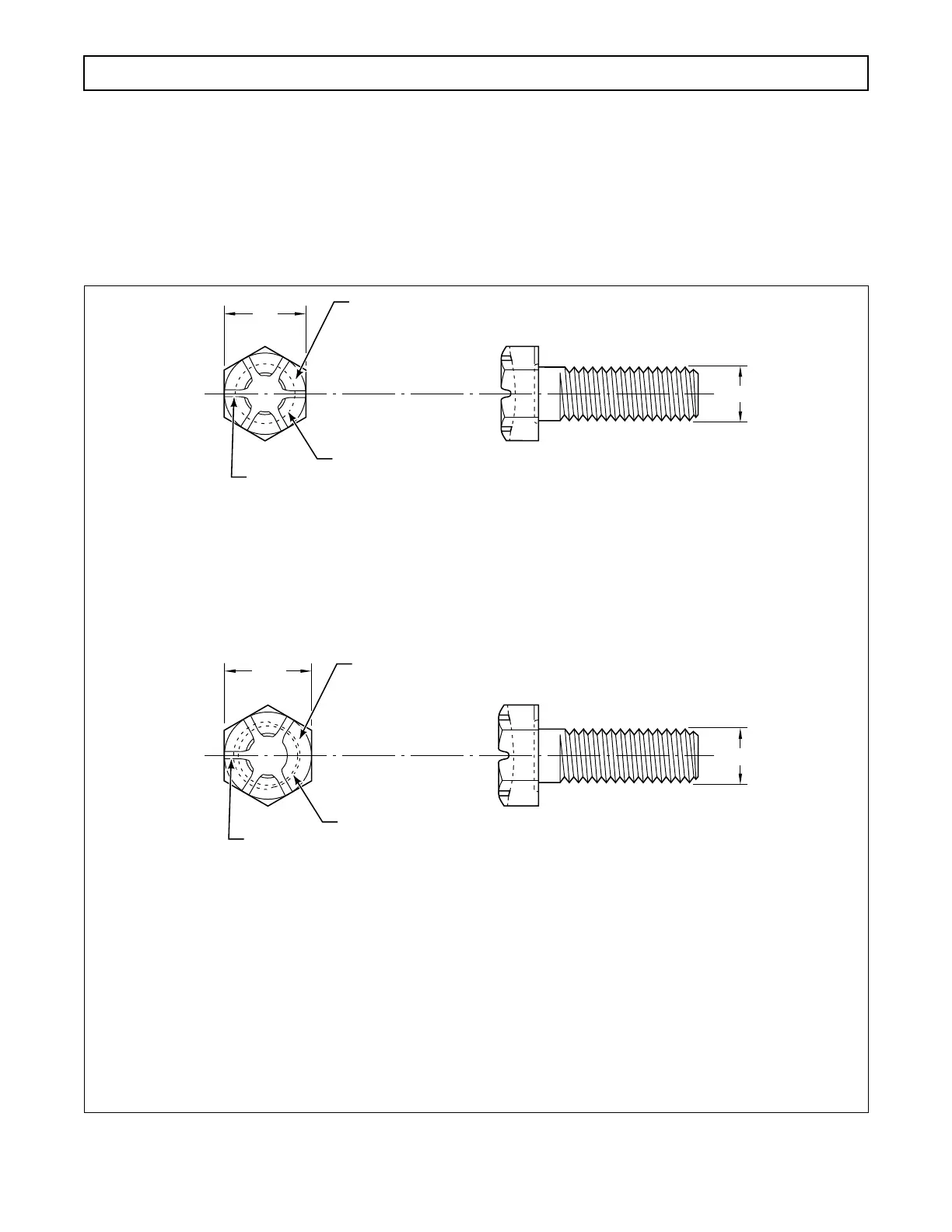

Figure 3–9. Identification of Flange Retaining Bolt

Source and material grade

identification markings to

appear on top of head in

this area

CONSTANT ANNULAR GROOVE

Six (6) radial slots spaced

sixty (60) degrees apart

3

⁄4 in.

1

⁄2 in.

V01301

13

⁄16 in.

1

⁄2 in.

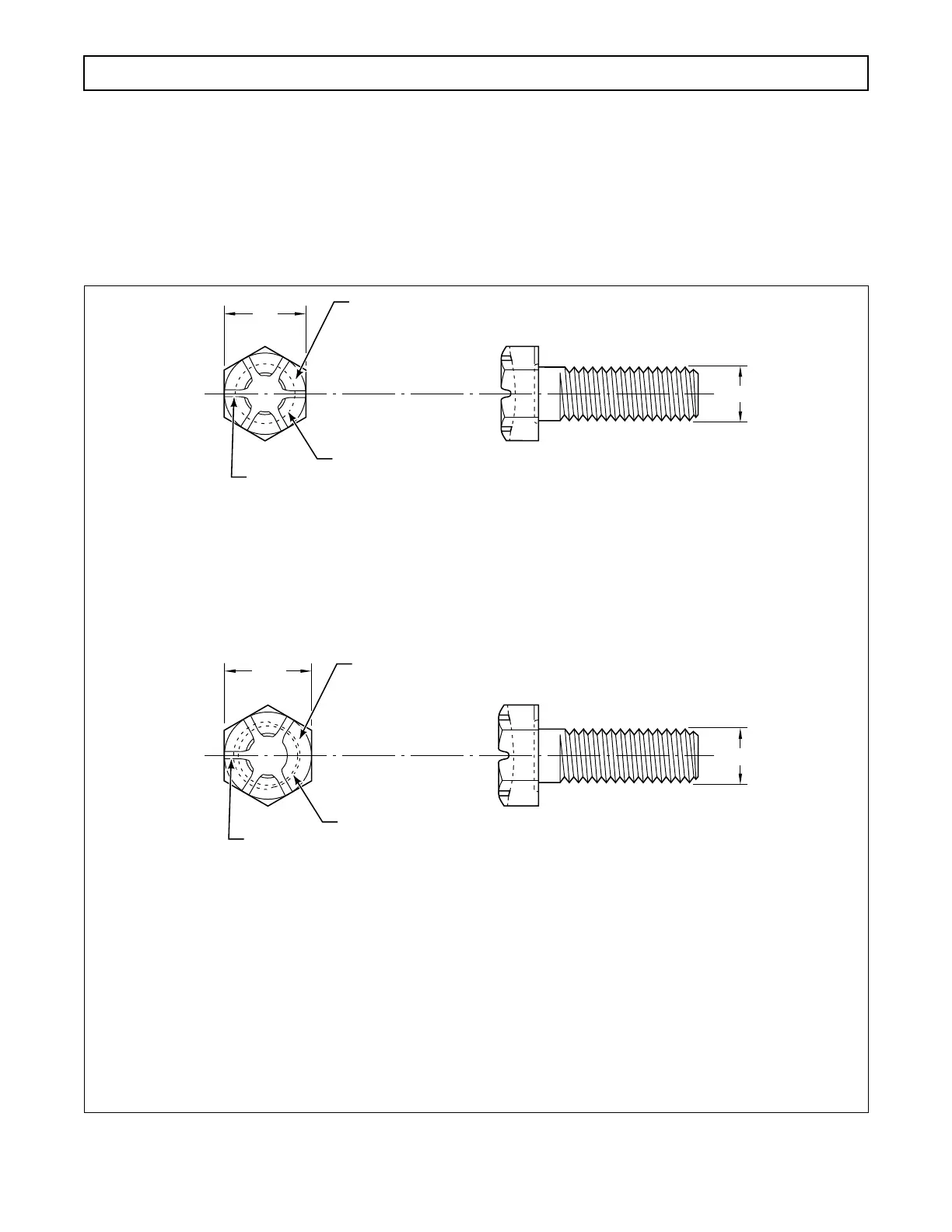

Source and material grade

identification markings to

appear on top of head in

this area

VARYING ANNULAR GROOVE

Five (5) radial slots spaced

sixty (60) degrees apart

EARLIER BOLT

P/N 23014159

STANDARD (TYPE AA PATCH) SAE GRADE 8

3

⁄4 in. HEXAGON HEAD

SIX (6) GRADE ID MARKINGS*

CONSTANT UNDERHEAD FILLET**

LATER BOLT

P/N 29510838

NON-STANDARD (TYPE BH PATCH) SAE GRADE 8

OFFSET,

13

⁄16

in. HEXAGON HEAD

FIVE (5) GRADE ID MARKINGS***

VARYING UNDERHEAD FILLET**

* Radial slots spaced approximately sixty (60) degrees apart.

** Annular groove at the junction of the head bearing surface and the bolt shank.

*** Radial slots spaced approximately sixty (60) degrees apart; may be random relative to hexagon but

shall be oriented such that three (3) wide slots are symmetrically over span of large recess diameter.

Loading...

Loading...