6–14 Copyright © 1996 General Motors Corp.

AT 500, 1500 SERIES AUTOMATIC TRANSMISSIONS

(6) If present, remove pipe plug 15 (at the

temperature sending unit location) or, if present, re-

move the temperature sending unit.

b. Assembly

(1) If removed, install

1

⁄2-14 pipe plug 15.

Tighten the plug to 16–20 lb ft (22–27 N

.

m).

(2) Place solenoids 7 in place in transfer

plate 14 and install pins 13. Install

1

⁄16 inch pipe plugs

12 to retain pins 13. Tighten plugs 12 to 35–50 lb in.

(4–5 N

.

m).

(3) In preparation for installation of harness

11, carefully strip wire insulation approximately

1

⁄4

inch (6 mm) (unless insulation crimp is over tight).

Automatic wire stripper J 35615 will remove the insu-

lation and crimp from the old terminal without damag-

ing the wire.

(4) Install harness 11, fitting feedthrough

seal 10 into transfer housing 14.

NOTE:

Terminals with white wires install in one connector

and terminals with red wires install in the other

connector.

(5) Install the terminals onto connectors 8 as

follows:

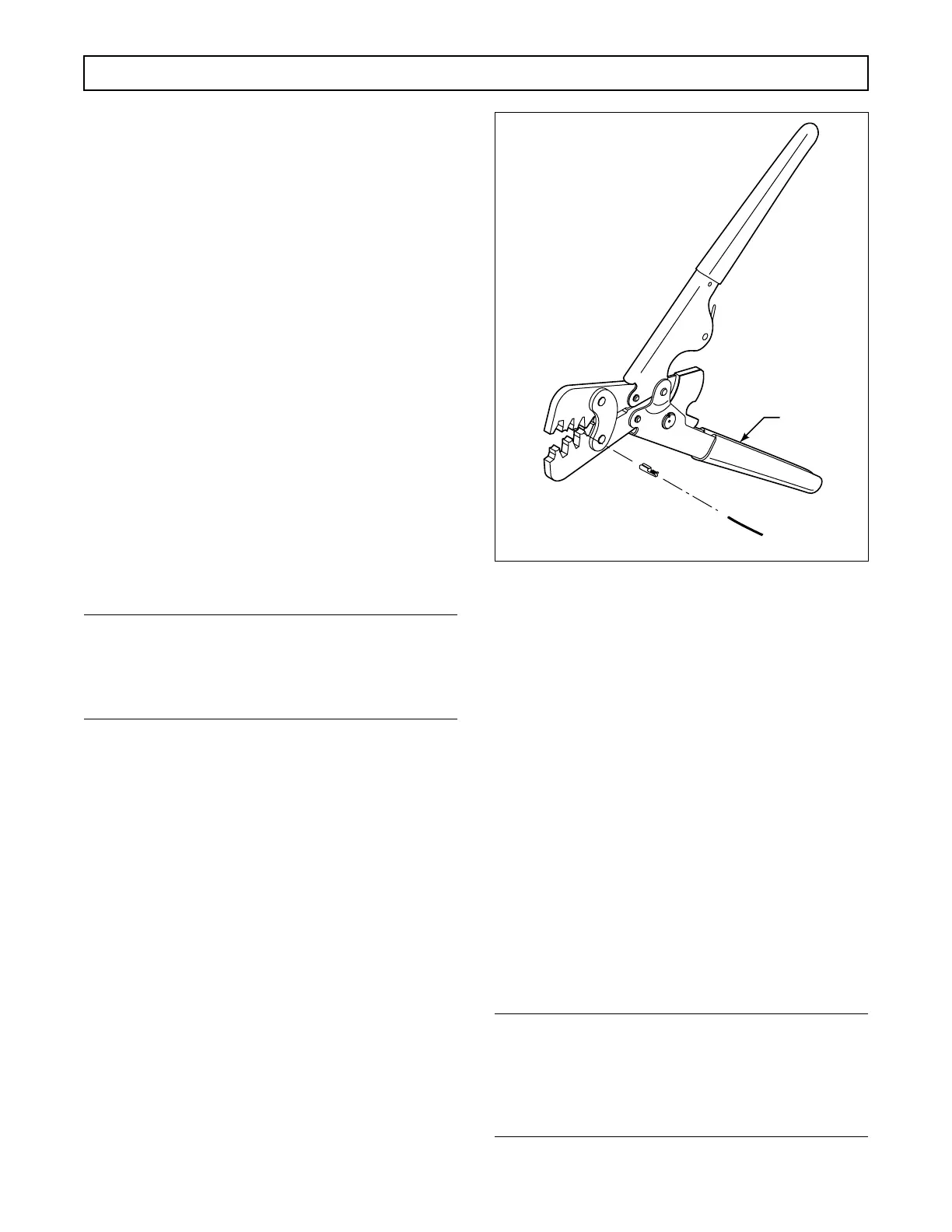

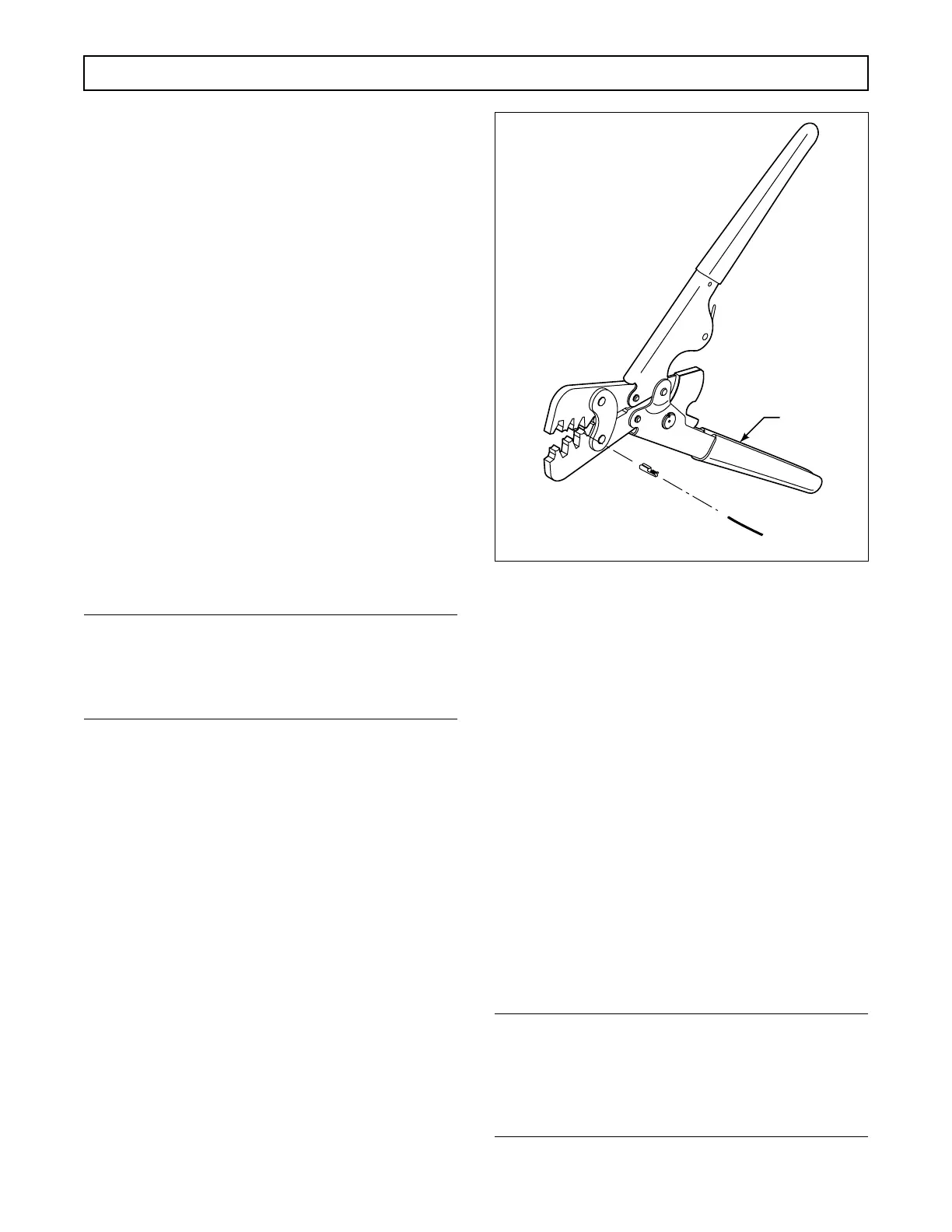

• Place core crimp portion of terminal on bed

of Anvil C on crimping tools J 38125-7 and

squeeze the crimper enough to hold the

terminal from dropping (Figure 6–23).

• Position the wire core in the terminal and

squeeze the crimper tool to complete the

core crimp.

• Position the insulation crimp of the terminal

on Anvil D so that the entire insulation

crimp area and a portion of the terminal

between the core and insulation crimp areas

are supported by the anvil. Complete the

insulation crimp.

• Slip the wire through the slot in the

connector and pull to fully seat the

terminal(s).

Figure 6–23. Terminal Installation

(6) Install snapring 9 to retain the harness.

(7) Connect two connectors 8 until they snap

into place on two solenoids 7. The connector with

white wires connects to the H (upper) solenoid; the

connector with the red wires connects to the F (lower)

solenoid.

6–9. OIL PUMP AND FRONT

SUPPORT ASSEMBLY

a. Disassembly (Foldout 7,B)

(1) Remove sealring 13 from front support 16.

(2) Remove six bolts 11 (eight, some mod-

els) and washers 12 from the front of pump body 8.

Discard the washers.

NOTE:

When removing bolts 28 and 29, if the five bolts are

of two different lengths, take note of the size and lo-

cation of the five bolts. The same size bolts will need

to be installed as are removed.

Loading...

Loading...