Copyright © 1996 General Motors Corp. 6–35

REBUILD OF SUBASSEMBLIES

b. Removal of Pinion Components

(1) Using a drill that is slightly smaller than

the pinion pin diameter, drill into the swaged end on

the pins (only one end required). Do not drill into the

carrier. The rear ends of all pinion pins except those in

the center carrier assembly will be drilled. Drill the

front ends of the center assembly pins.

(2) Place press fixture J 25587-1 in a hy-

draulic press. Select the proper spacer and adapter, if

required, from the tool chart and Figure 6–59. Position

these parts (if used) to support the carrier assembly

(drilled ends of pinion pins upward) solidly on the

press fixture.

(3) Install pin remover J 25587-16 into the

ram of the press fixture. Press the pinion pins from the

carrier assembly.

(4) Remove the pinion groups, consisting of

pinions, bearings, and thrust washers.

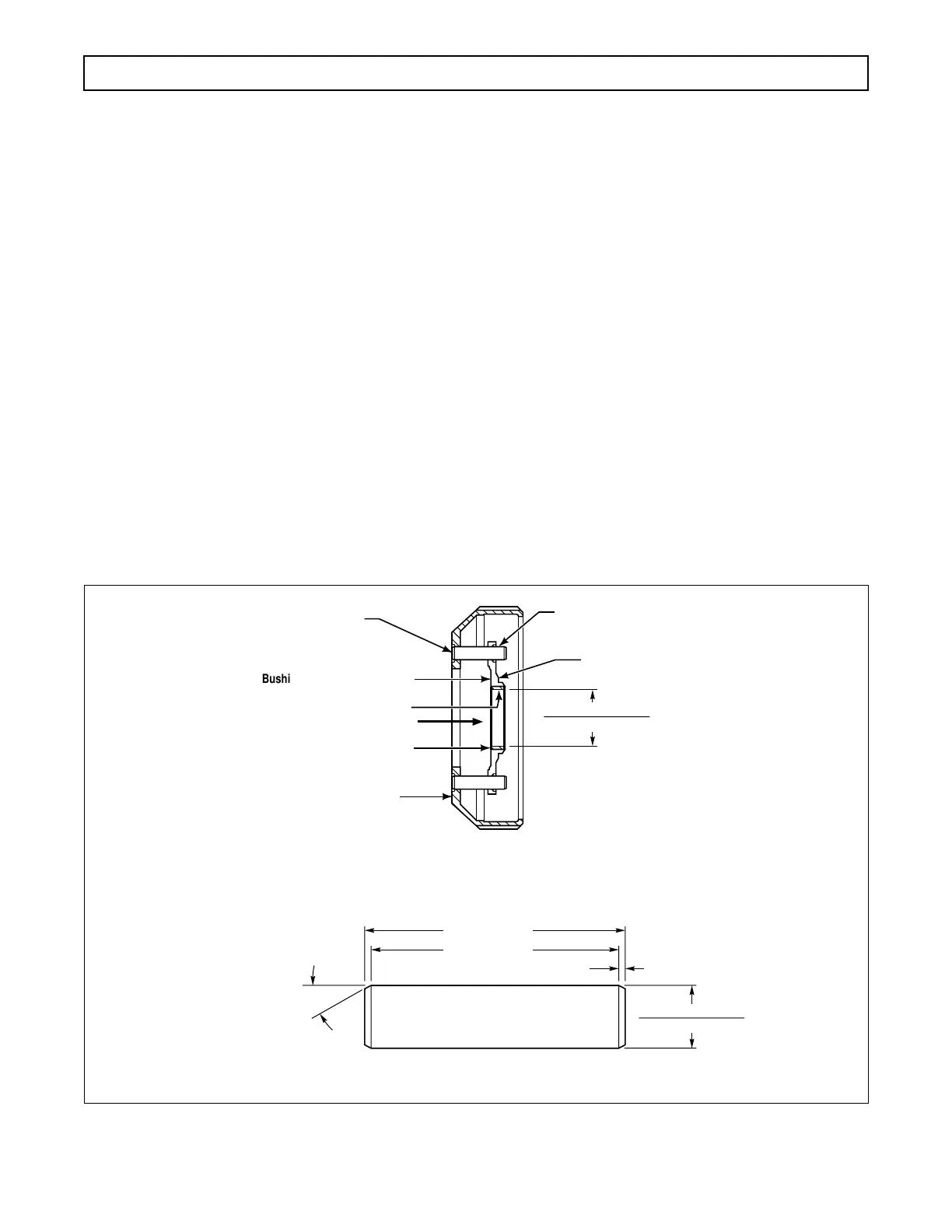

c. Replacing Bushing in

Front Planetary Carrier

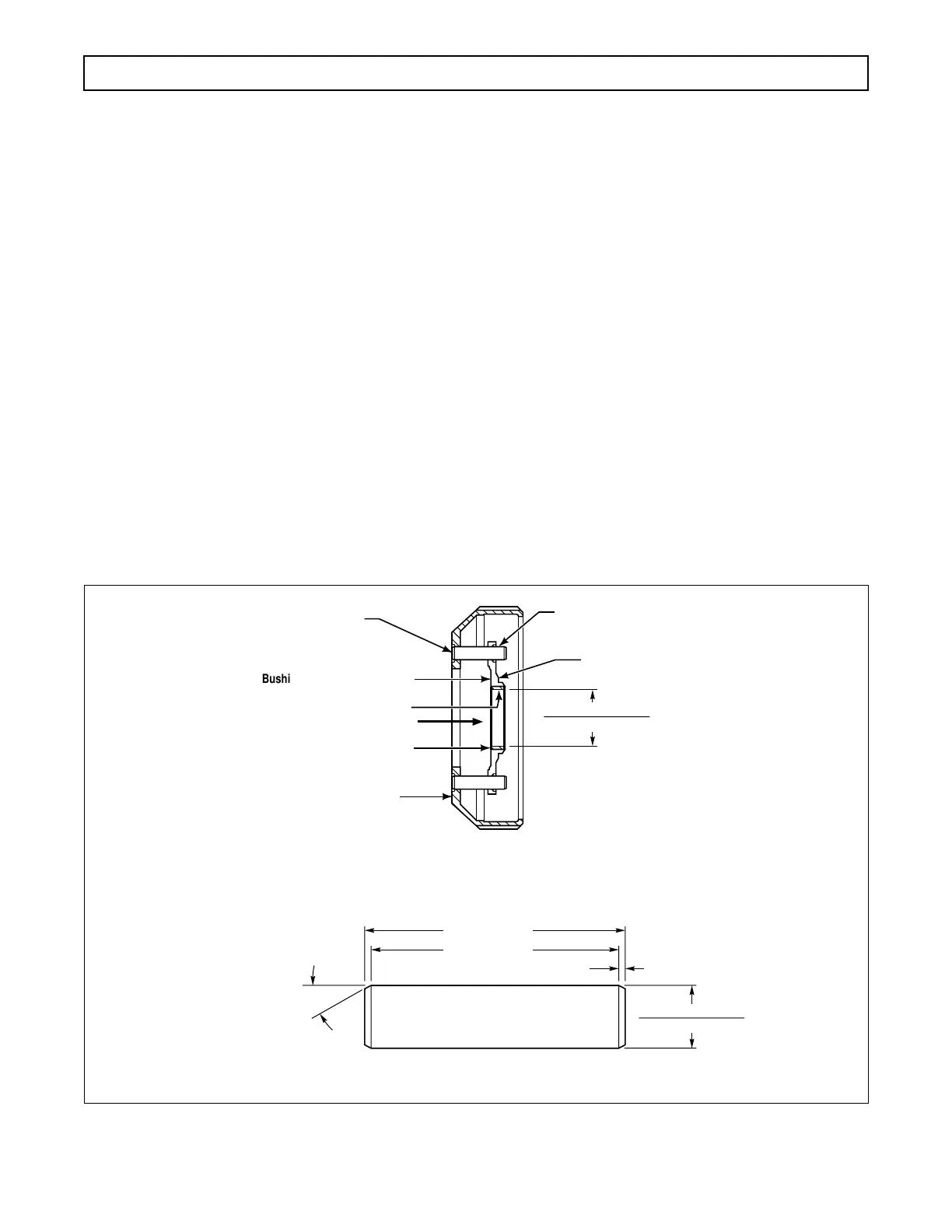

(1) Fabricate four dummy pins to the dimen-

sions shown in Figure 6–60.

(2) Place the front carrier on a work table,

rear downward.

(3) Press the bushing from the carrier. Do

not scratch or score the bushing bore. (Refer to Para-

graph 4–5f(1).)

(4) Place the carrier in a press, rear down-

ward.

(5) Apply Loctite

®

Sleeve Retainer No. 601

(or equivalent) to the OD of the new bushing. Install

the bushing using tool J 28501. Press the bushing

flush to 0.010 inch (0.25 mm) below its adjacent sur-

face (Figure 6–60). Remove excess Loctite

®

from the

carrier.

Figure 6–60. Front Carrier Assembly Bushing Installation

Bushing to be flush to 0.010 in.

(0.25 mm) below this surface

Bushing installation load must be

525 LB (2335 N) in direction shown

BUSHING

DUMMY PINS (6)

SURFACE

A

SURFACE B

DIA A

Diameter A must be perpendicular with surface B within 0.001 in. (0.02 mm) TIR.

With respect to surface B and the true position of the six (6) dummy pins,

diameter

A shall be within the total runout specified by C.

Adjust chuck jaws to achieve

“0” TIR (this locates true

position of dummy pins)

C 0.002 in. (0.05 mm) TIR

2.50 in. (63.5 mm)

2.45 in. (62.2 mm)

0.025 in. (0.63 mm)

0.5117 in. (12.997 mm)

0.5114 in. (12.510 mm)

1.7534 in. (44.536 mm)

1.7524 in. (44.510 mm)

DUMMY PIN

30°

V02273.01

Loading...

Loading...