Copyright © 1996 General Motors Corp. 6–19

REBUILD OF SUBASSEMBLIES

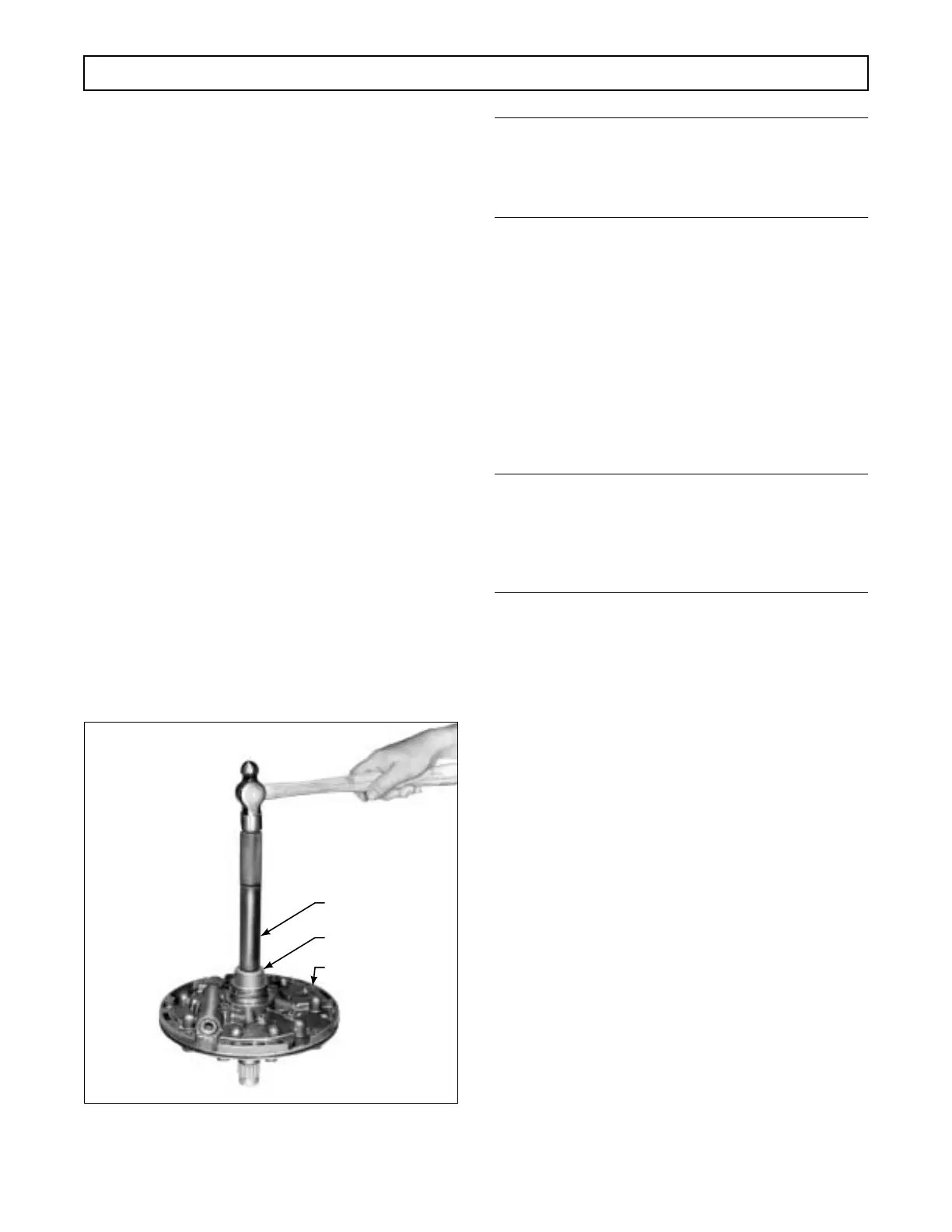

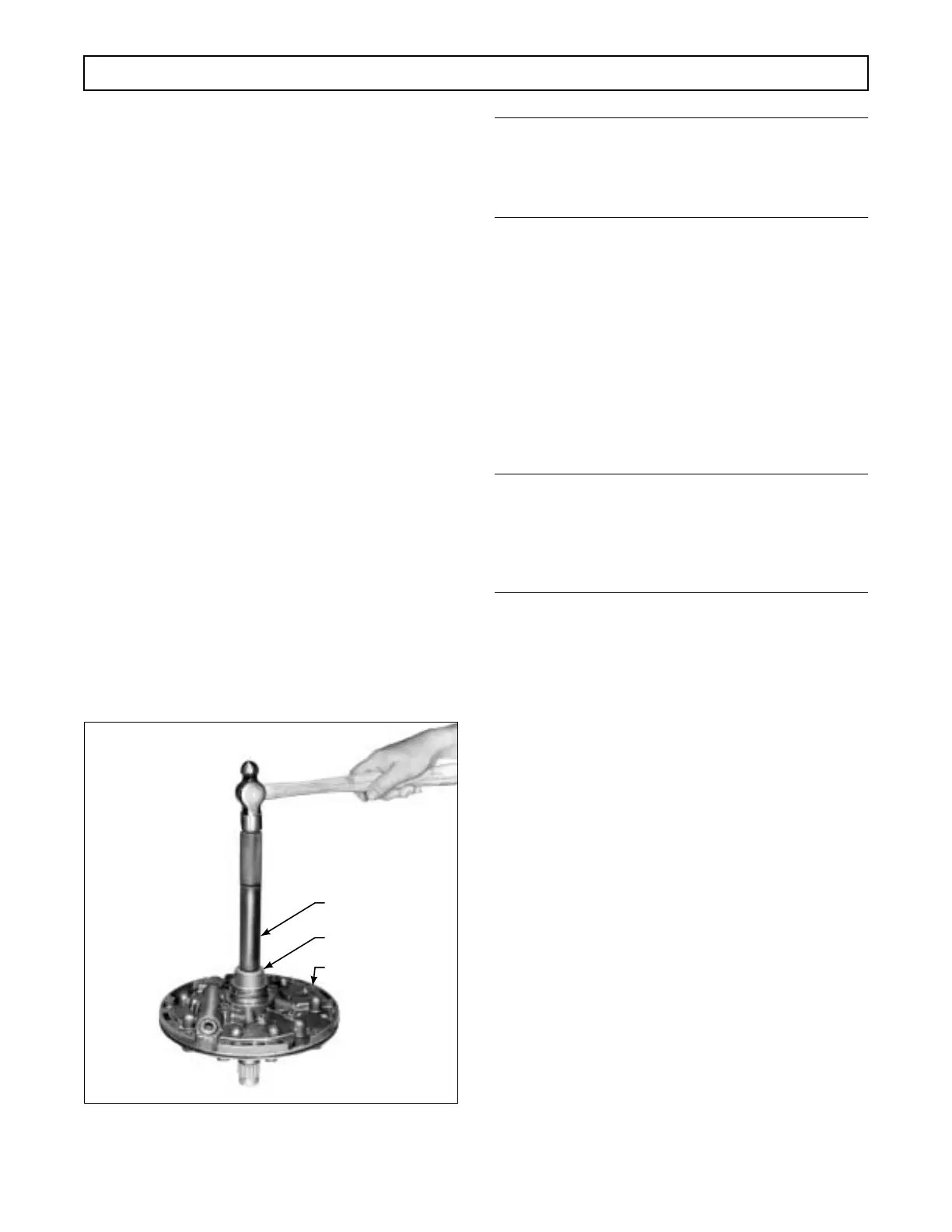

(1) For models without lockup, if roller bear-

ing 23 was removed, using installer J 23615, press on

the lettered end of the new bearing to a depth of

0.595–0.615 inch (15.11–15.62 mm) from the end of

the shaft (Figure 6–32).

(2) Install valve plug 14 (earlier models) into

the main pressure regulator valve bore of front support

21. Install pin 15 (earlier models) into the pump body

side of front support 21. Skip Step (3) and proceed

with Step (4).

(3) For models with lockup, if roller bearing

23 was removed, using installer J 39794, press on the

lettered end of the new bearing to a depth of 0.625–

0.635 inch (15.88–16.12 mm) from the end of the

shaft.

(4) Install main-pressure regulator valve 27,

smaller end first, into its valve bore.

(5) Into the same bore, install valve spring

26 and spring stop 25 (smaller end first).

(6) Install main-pressure regulator valve in-

staller tool J 24787 (Figure 6–24). Restrain spring stop

25 (Foldout 7,B) and install snapring 24, flat side out-

ward. Remove the tool from the assembly.

Figure 6–32. Installing Stator Shaft Rear Bearing

(Models without Lockup)

NOTE:

• For models without lockup, skip Step (7) and

proceed with Step (8).

• For models with lockup, proceed with Step (7).

(7) For models with lockup, install lockup

valve 30 (Foldout 7,B), smaller end first, into pump as-

sembly 16. Into the same bore install spring 31 and

stop 32. Restrain stop 32 and install pin 33 through the

machined side of the front support.

(8) If either plug 20 or 22 was removed, in-

stall a new plug. Press plug 20 into the support to a

depth of flush to 0.010 inch (0.25 mm) below the sur-

face. Press plug 22 to the shoulder in the support.

NOTE:

• For models without lockup, proceed with

Step (9).

• For models with lockup, skip Steps (9) and (10),

and proceed with Step (11).

(9) For models without lockup, if bushing 7

was removed, install a new bushing. The split in the

bushing must be located in an area of the bore that can

completely support it. Use installer tool J 25356 to

press the bushing into the front of the pump body to a

height of 0.010–0.020 inch (0.25–0.51 mm) above the

surface.

(10) Using special installer tool J 21359-A,

install oil seal 3, with the lip facing inward (Figure

6–33). Skip Steps (11) and (12) and proceed with

Step (13).

(11) For models with lockup, if bushing 7 was

removed, install a new bushing. The split in the bush-

ing must be located in an area of the bore that can

completely support it. Use installer tool J 39739 to

press the bushing into the front of the pump body to a

depth of flush to 0.398 inch (10.11 mm).

(12) Using special installer tool J 39757, in-

stall oil seal 3 with the lip facing inward (Figure 6–33).

(13) Lubricate and install sealring 4 (Foldout

7,B) onto pump body 8. Lubricate and install driven

gear 9 and drive gear 10.

H02939

PUMP ASSEMBLY

J 23615

J 8092

Loading...

Loading...