15

Installation, Operation & Maintenance Manual

OXYvisor Optical Oxygen Analyzer

The OXYvisor analyzer uses a quench uorescence technique with a sensor optically isolated from the

process, using the absorbency as a diagnostic function and analyzing the phase angle for measurement of the

analyte, oxygen, in the modulated time domain. This gives the analyzer the ability to measure accurately and

precisely under various and changing ambient and process conditions.

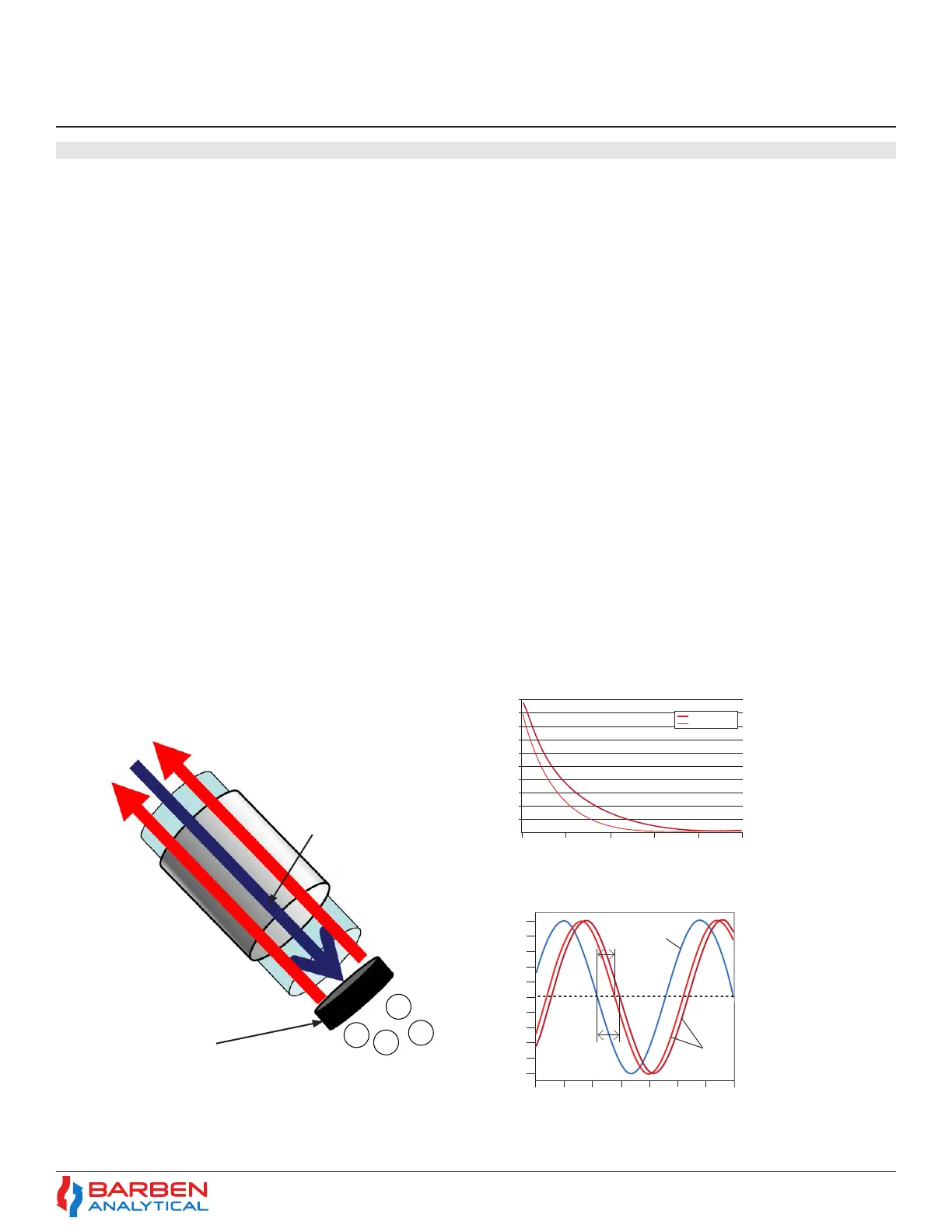

The analyzer uses an LED to emit blue light through ber optic cable down to the luminophore which resides

at the sensor tip [Fig 1]. The luminophore absorbs the energy and rises to an excited state indicated by red

light returned back through the ber optic cable. The properties of the emitted light are measured through a

photomultiplier tube back at the spectrometer within the analyzer.

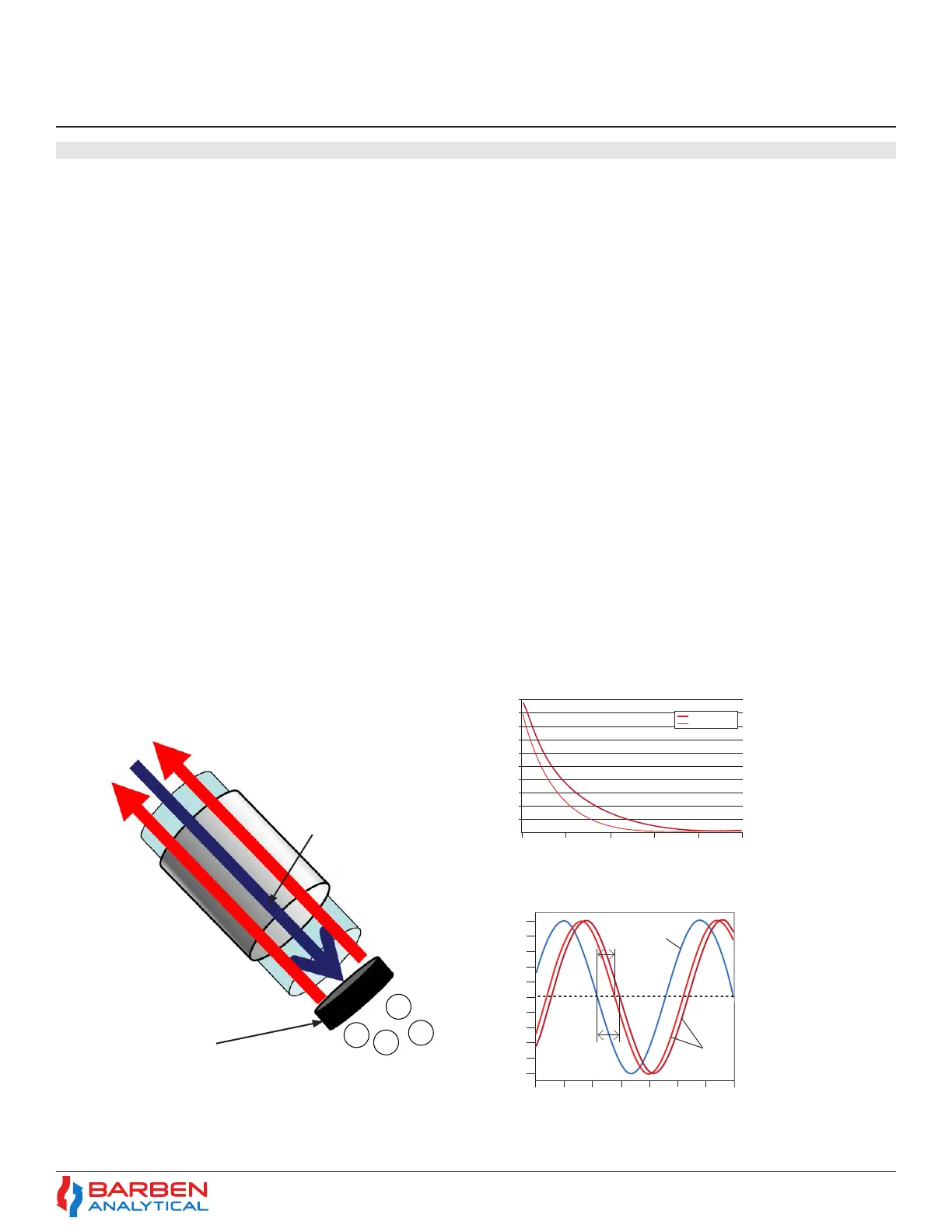

In the absence of oxygen, the excited luminophore will fall back to its ground state at a specic intensity

and phase angle. When oxygen is present it quenches the uorescence at a lower rate proportional to the

oxygen concentration [Fig 2.]. The phase shift and intensity dierences between the excitation source and the

uorescent signal is measured and the oxygen concentration is calculated [Fig 3].

The resulting measurement is specic to oxygen concentration. The luminophore is unaected by other

constituent gases and ow rate. The measurement is applicable in both gas and liquid phase. Temperature

compensation is required to account for quenching eciency at dierent temperatures and pressure

compensation is required to measure at process pressured dierent than the pressure at time of calibration.

O

2

O

2

O

2

O

2

Fiber optics transmits light

and receives emitted light

back from the luminophore

Oxygen sensitive luminophore

exposed to the process liquid

Figure 1 - Light Transmission

Figure 2 - O

2

Quenching Intensity vs Time

Figure 3 - O

2

Quenching AC Modulation

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

Intensity

-5 0 5 10 15 20 25 30

Time (µseconds)

ϕ

1

ϕ

2

reference

signal

measuring

signal

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

Intensity

0 5 10 15 20 25

Time (µseconds)

0% Oxygen

100 ppm Oxygen

Effects of 100 ppm oxygen quenching

The eect of O2

quenching on light

intensity from the

luminophore sensor is

shown above. Light

emitted from the

excited luminophore

has higher intensity

over a longer period

than when oxygen is

present. The intensity

and time are measured

by the spectrometer

withing the OXYvisor

to provide an oxygen

measurement.

AC modulation of the

blue light results in a

similar waveform of the

emitted red light from

the luminophore sensor.

The presence of oxygen

causes a phase shift

between Փ1 and Փ2 of

the red light waveform.

Measurement of

this phase shift

proportionally matches

the loss of intensity

shown in Fig 2 above.

The combination of

both measurement

techniques provides a

stable, accurate method

to measure oxygen in

liquid and gas phase

applications.

Light transmission through ber optic to luminophore

AC modulation and the phase shifted output

2.5 General principle of operaon

Section 2

Technical Product Specication

Loading...

Loading...