30

Installation, Operation and Maintenance Manual

OXYvisor Optical Oxygen Analyzer

Input /Output wiring requirements:

• 26 to 16 gauge (IEC .400 to 1.25)

• Copper, stranded wire

• Minimum 300V Insulation

• Tightened (torque) to .22 to .25 Nm

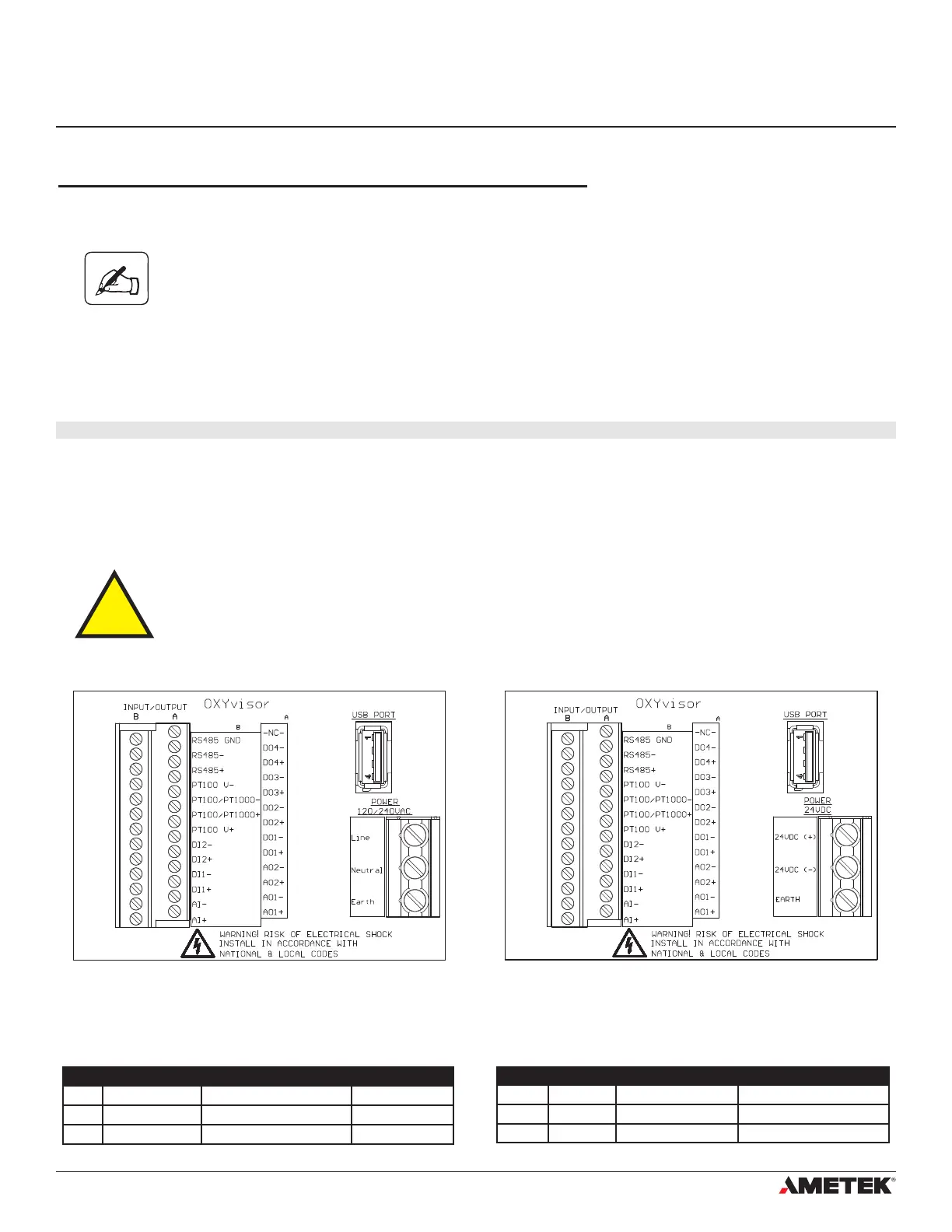

Input / Output Wiring

All Input / Output wiring for the OXYvisor analyzer is located on the left side of the board as shown in Figure (9)

and (10). The wiring assignments are shown in Table (1).

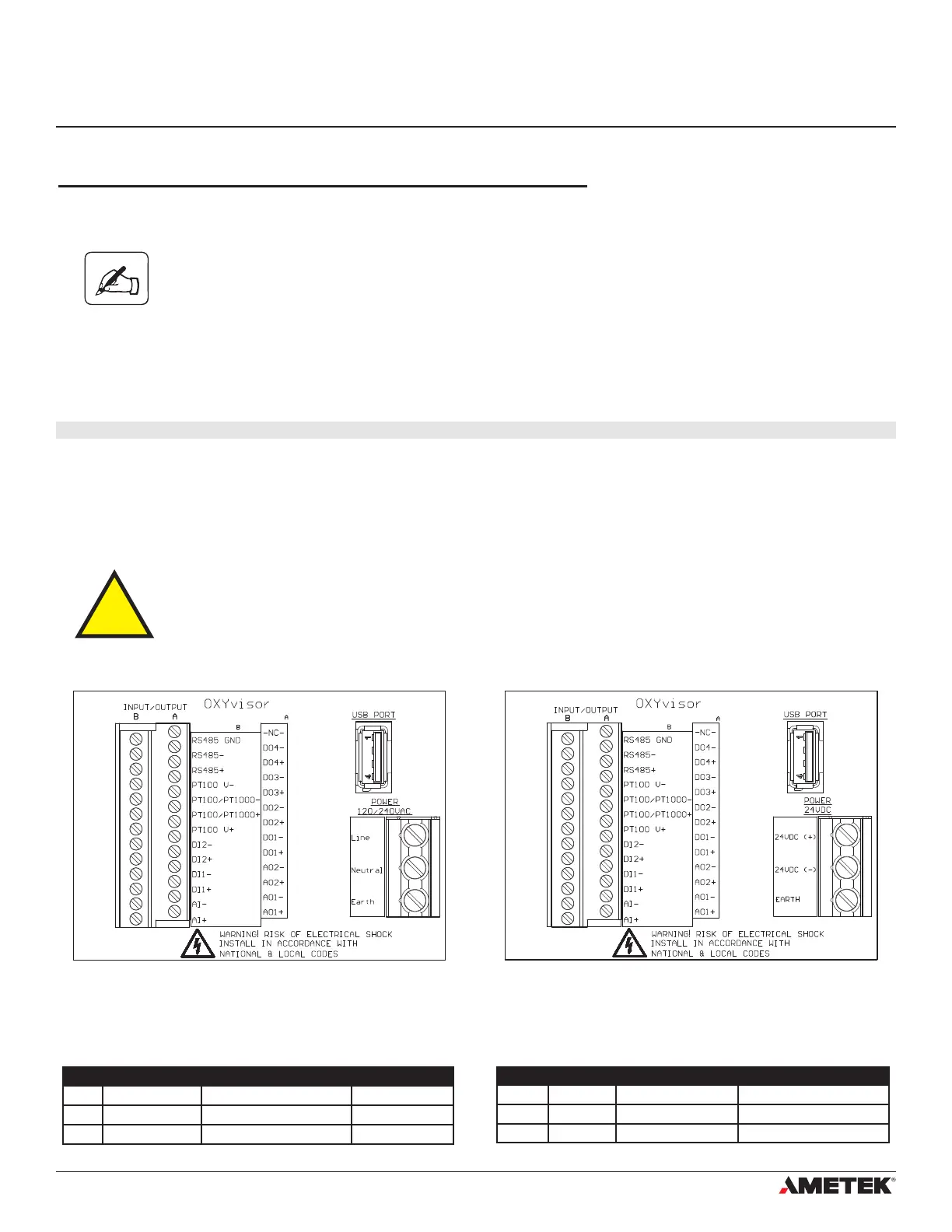

Please note that the 24VDC version of the analyzer is a 4-wire device. It has

separate wiring for power and signal (not a loop powered device).

4�6�3 DC Powered Analyzer

DC Power

OXYvisor analyzers ordered with DC power input will have a termination board labeled with “24VDC (+)”,

“24VDC (-)”, and “Earth” (Ground) as shown in Figure (10).

Analyzer - Power Supply Connections (DC Version)

The OXYvisor control unit can operate using 24 VDC +/-10%. When energized by mains the 24 V DC supply

must be from a Class2 or LPS source, OR that a fuse (1 A) will be required in the installation.

4�7 Wiring - Input/Outputs

Label Terminal Description Function

Line Power 120/240VAC 85-264 VAC 47/63Hz Input Power Line Power wiring

Neutral Power 120/240VAC 85-264 VAC 47/63Hz Input Power Neutral Power Wiring

Earth Power 120/240VAC Earth Terminal Earth Terminal

Label Terminal Description Function

24VDC (+) Power 24VDC 21.6 - 26.4 VDC Positive DC Power wiring

24VDC (-) Power 24VDC 21.6 - 26.4 VDC Negative DC Power Wiring

Earth Power 24VDC Earth Terminal Earth Terminal

AC TERMINAL BOARD POWER WIRING DC TERMINAL BOARD POWER WIRING

Terminal

Terminal

Terminal

Terminal

Figure 13 - AC Terminal Board - Located in Rear (Wiring) Compartment Figure 14 - DC Terminal Board - Located in Rear (Wiring) Compartment

Section 4

Installation

Loading...

Loading...