75

Installation, Operation & Maintenance Manual

OXYvisor Optical Oxygen Analyzer

The following setting are used to communicate with the OXYvisor as a Slave Device.

The OXYvisor Modbus RTU protocol uses a subset of the standard Modbus RTU function codes to provide

access to process-related information. Several standard function codes are employed and supported, shown

in the table below. These standard function codes provide basic support for IEEE 32-bit oating point numbers

and 16-bit integer register representation of instrument’s process data.

A7.2 - Conguraon

A7.2.1 - Sengs

A7.2.2 - Funcon Codes

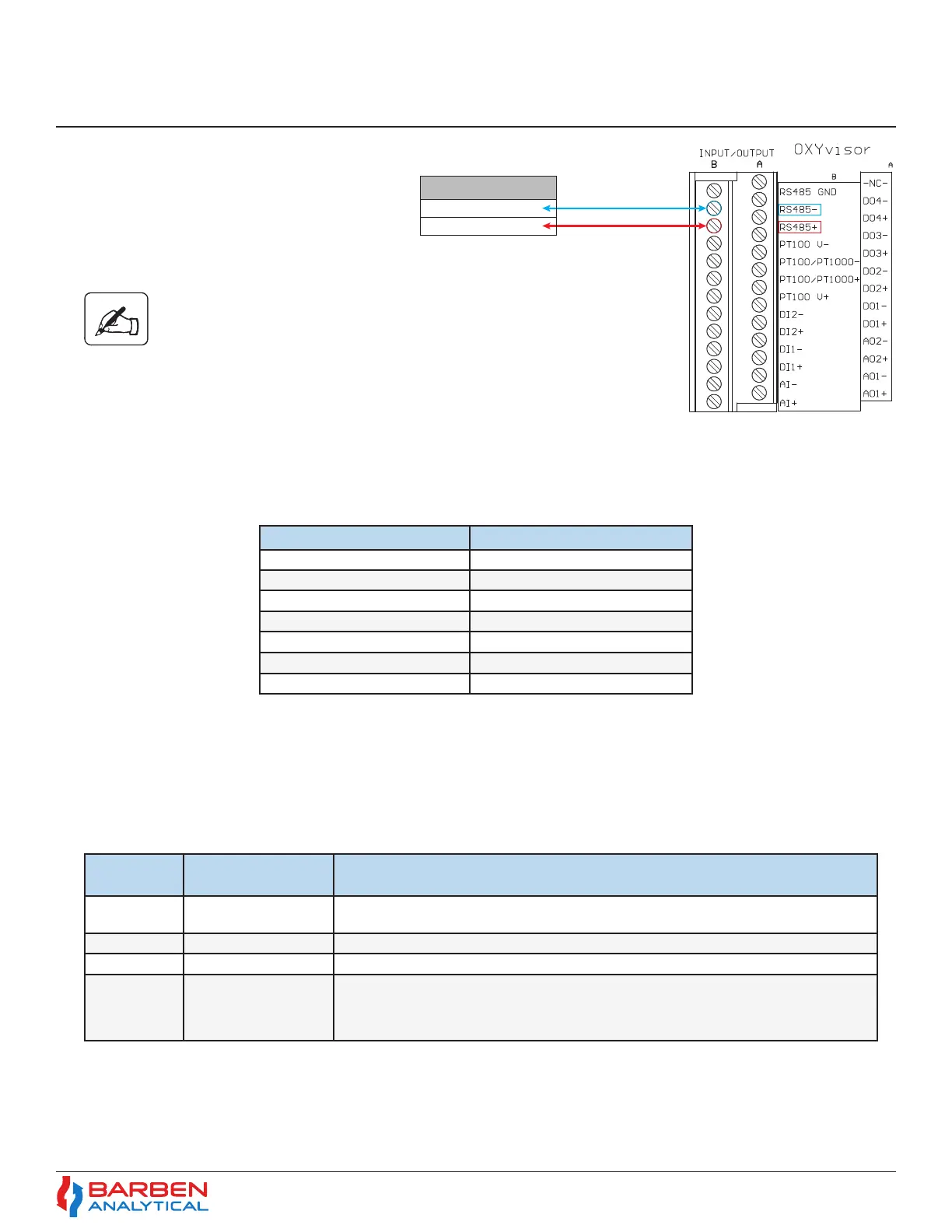

Terminal

Terminal

RS-485 Master

Data (B) -

Data (A) +

< 4000 ft (1220 meters)

The maximum distance of RS-485 without using a repeater is

4000 feet (1220 meters) at baud rates up to 90Kbps. Extend that

distance by adding an RS-485 Repeater or Optically Isolated

Repeater every 4000 feet.

Setting Value

Mode RTU

Baud rate 115200

Data Bits 8

Stop Bits 2

Parity None

High Byte First

Slave ID 01, 02, …

Function

Code

Name Usage

03 Read Holding Registers Read Data in 16-bit Register Format (high/low). Used to read integer or oating-point process

data. Registers are consecutive and are imaged from the instrument to the host.

04 Read Input Registers

06 Write Single Register Write Data in 16-bit Integer Format (high/low) ONLY.

16 Write Multiple Registers Write Data in 16-bit Format (high/low). Used to write integer and oating-point override data.

Registers are consecutive and are imaged from the host to the instrument.

Note: Can write oating point data using this Function Code

Figure A.34 - Modbus Connection

Loading...

Loading...