Installation Guide | 3-9

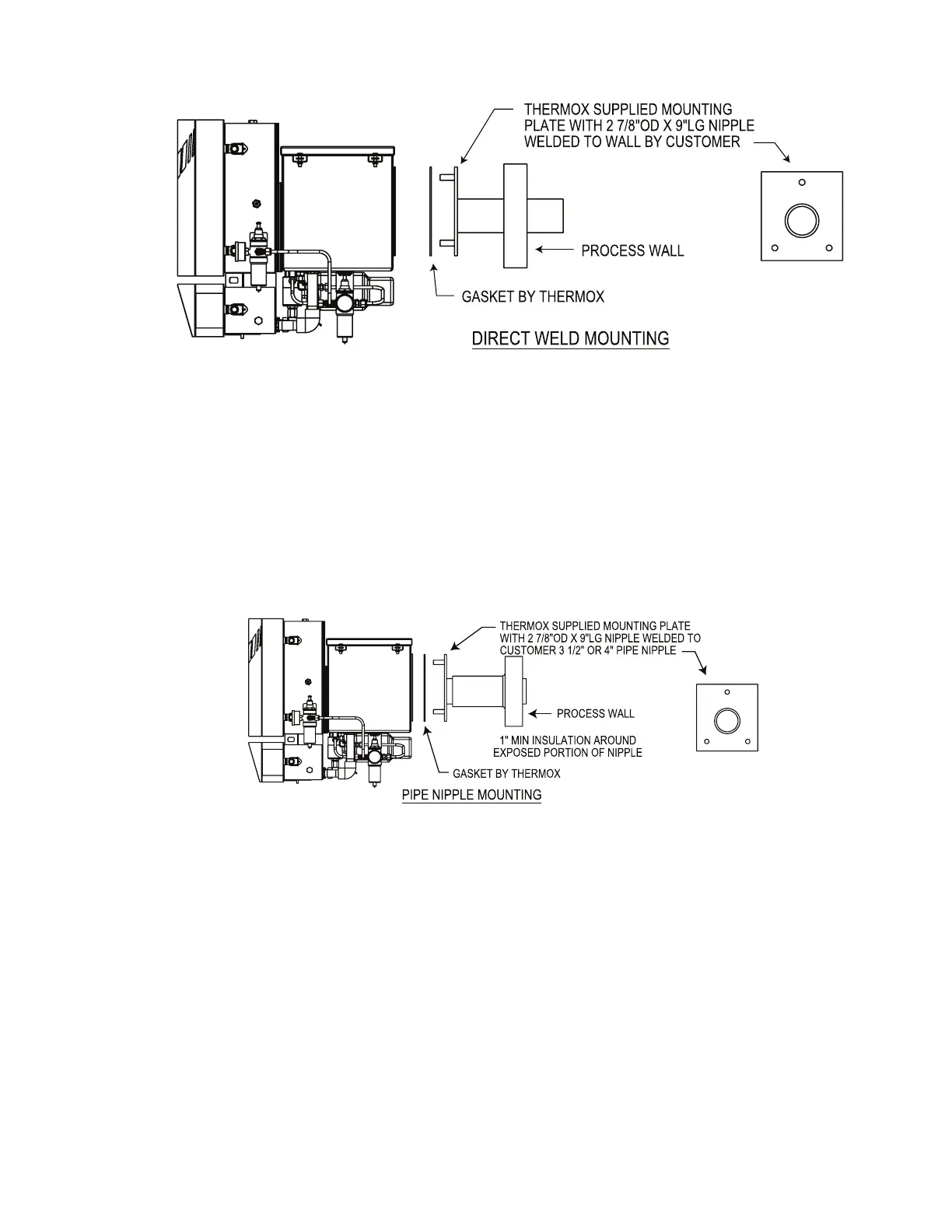

Figure3-8.WDG-Vsensorushmount(preferred).

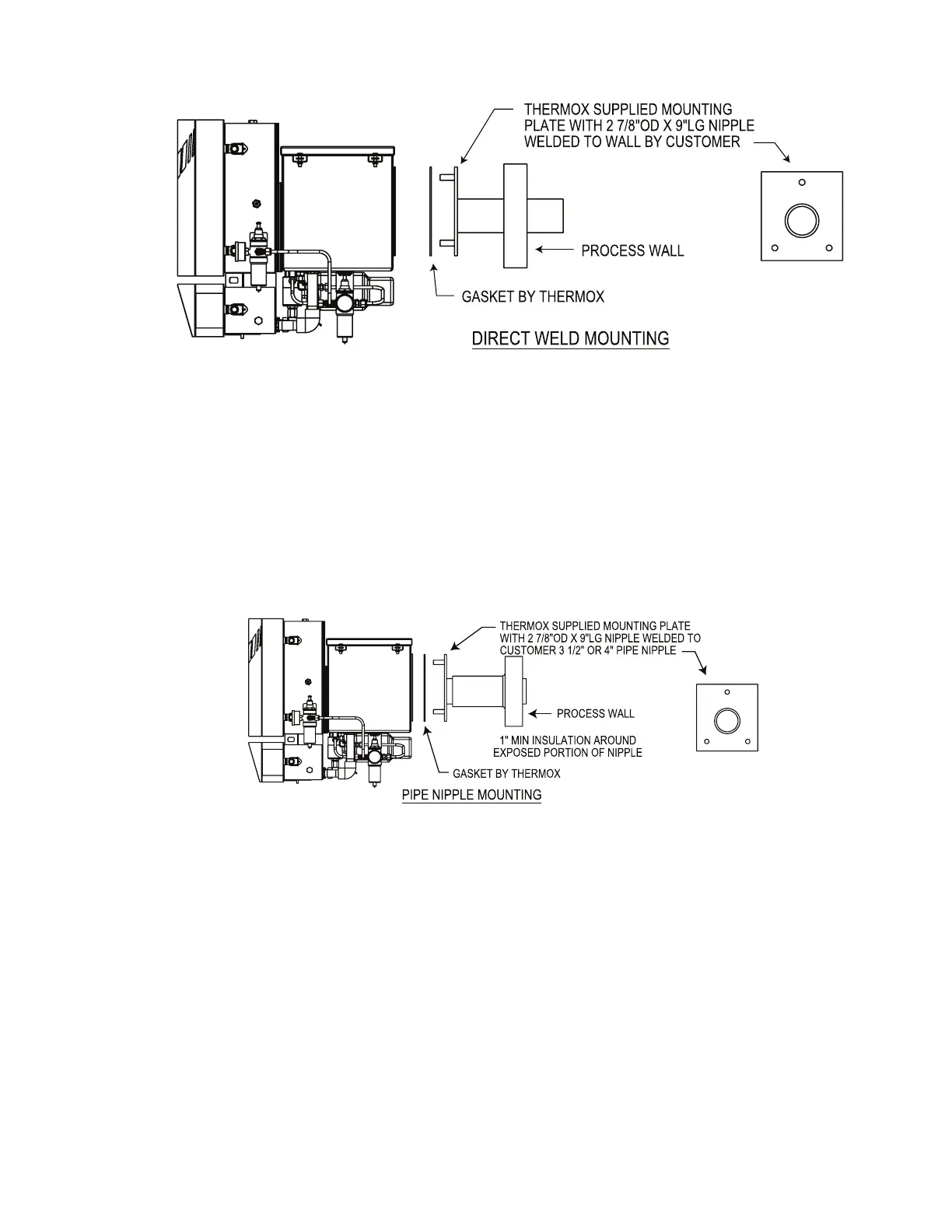

Customer-supplied pipe nipple sensor mounting

If you can’t mount the sensor flush with the process as described in the

previous section (for example, the process wall is curved sharply, covered

with insulation, or obstructed with reinforcing members) you can instead:

1. Weld a short 3 1/2” diameter pipe nipple to the process wall and make

sure to extend the nipple through the skin of the process (see Figure

3-8).

Figure 3-9. Customer-supplied pipe nipple sensor mounting.

•

2. Weld the 7” x 7 5/8” (17.78 cm x 19.37 cm) supplied plate to the end of

the nipple, taking care to center it over the hole

3. Wrap the nipple with at least 1” (2.54 cm) weatherproof insulation and

heat trace it.

4. Bolt the sensor to the plate.

If mounting the sensor using this method, you can also install the probe

heater to minimize the possibility of the sample gas cooling below its dew-

point.

Loading...

Loading...