154 ASC 110

3.6. Individual Operations of Maintenance

Observe cleanliness at work. Avoid con-

tamination of the system with materials

that may cause damage to crucial units!

Do NOT open hydraulic tank uselessly!

When cleaning the tank, use cleaners

with no bre-slip, do not use chemical

detergents.

Rell oil according to par. 3.2.4.

Exchanging the lter element of pressure lter

! NOTE !

Exchange the lter element always in the following

occasions:

- when changing oil

- if the signal lamp of pressure lter lights up

after the working temperature reached 50

through 60 °C (122 - 140 °F).

Use original lter elements according to

spare parts catalogue only.

Exchange oil and lter always when a

destruction of internal parts of the units

occurs (of hydromotors, of hydrogenera-

tors), or during a major overhaul of the

hydraulic system. Clean and rinse out

the hydraulic tank before installing new

unit, and ll it with oil. With the engine

running at increased speed, please test

the functions of the Machine. Check the

tightness.

Used lter elements are environmen-

tally dangerous waste - have them

liquidated.

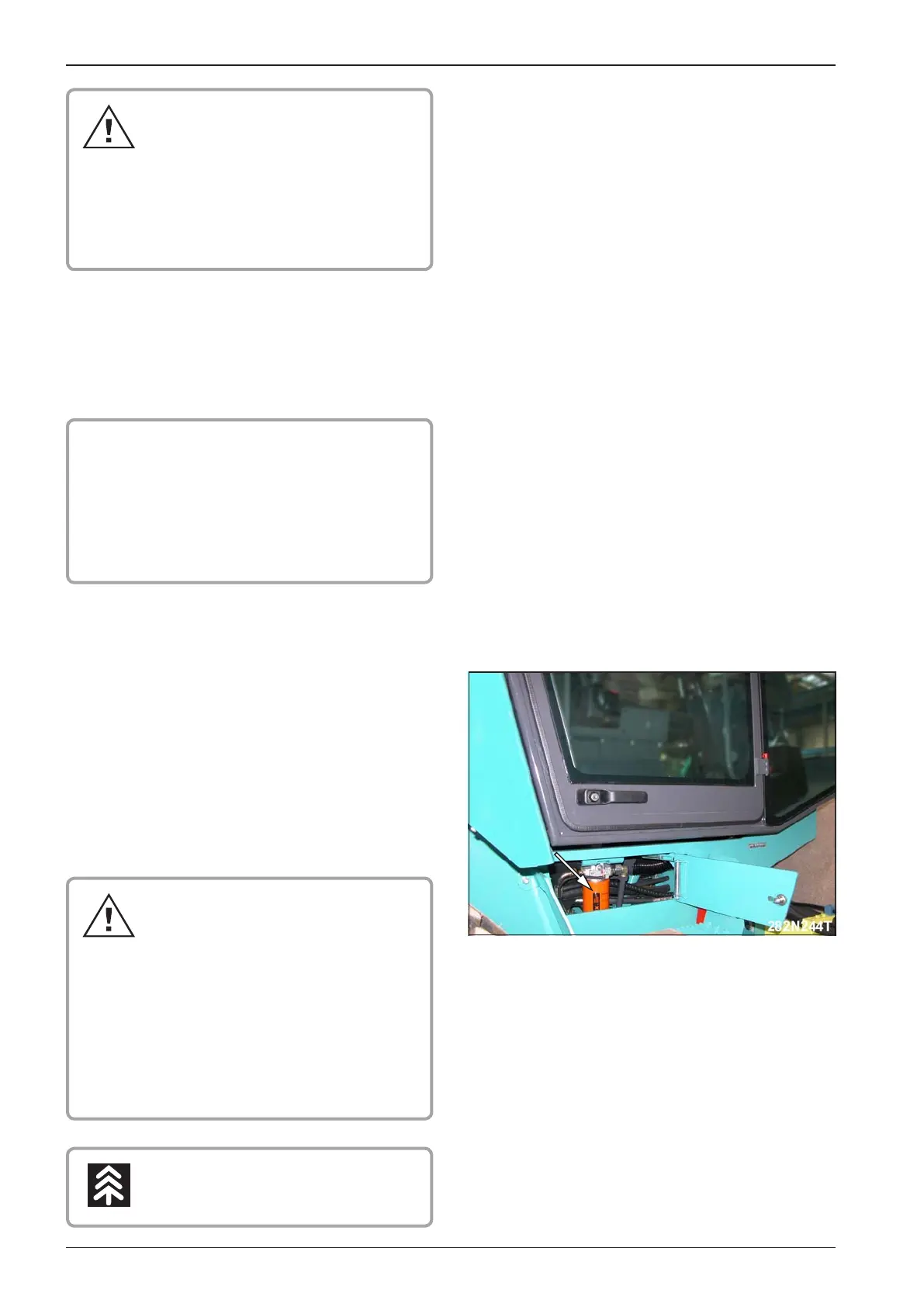

Remove the lter. Clean from below the following: contact •

surface of the ltration block, spread pure oil over the new

lter’s ring, screw down, tighten.

Loading...

Loading...